High precision checkweigher adopts advanced weighing technology and simple design method, which is economical and affordable, ensuring stable and reliable check weighing accuracy and speed. It has optional three-zone and five-zone checkweighing function, and up to 5 weight zones can be divided.

High precision checkweigher adopts advanced weighing technology and simple design method, which is economical and affordable, ensuring stable and reliable check weighing accuracy and speed. Checkweigher for daily necessities has optional three-zone and five-zone checkweighing function, and up to 5 weight zones can be divided.The special 10-inch color LCD display for the checkweigher has a beautiful and simple operation interface. It can also count and display production data at the same time.For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

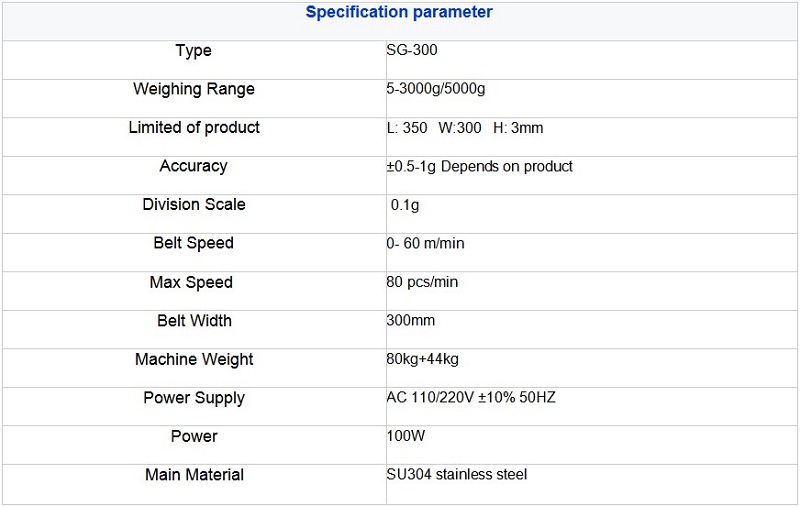

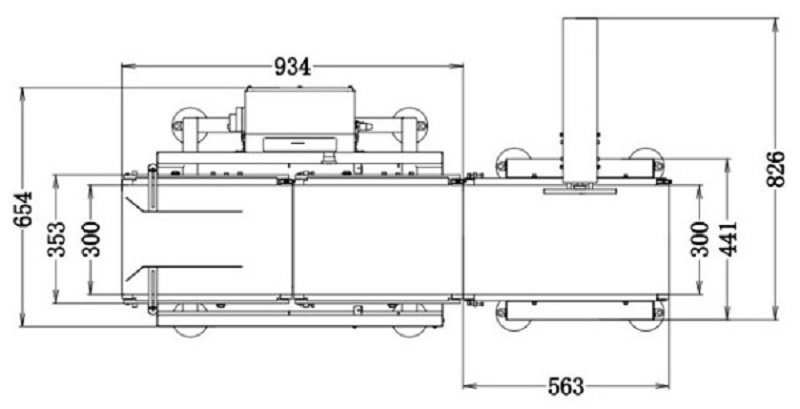

PS:The display size is the size of the standard model, and the size can be customized according to actual needs.

High precision: use imported high-speed weighing module and weight sensor to ensure detection accuracy

Simple structure: The whole dynamic checkweigher is made of stainless steel. The structure is simple and easy to maintain and maintain. It conforms to GMP and HACCP specifications

Convenient operation: Schneider touch screen is used for simple operation, intuitive display and support for multiple languages (default Chinese and English)

Convenient external connection: It can be connected to other equipment in the production line, such as printer labeling machine and inkjet printer, etc.

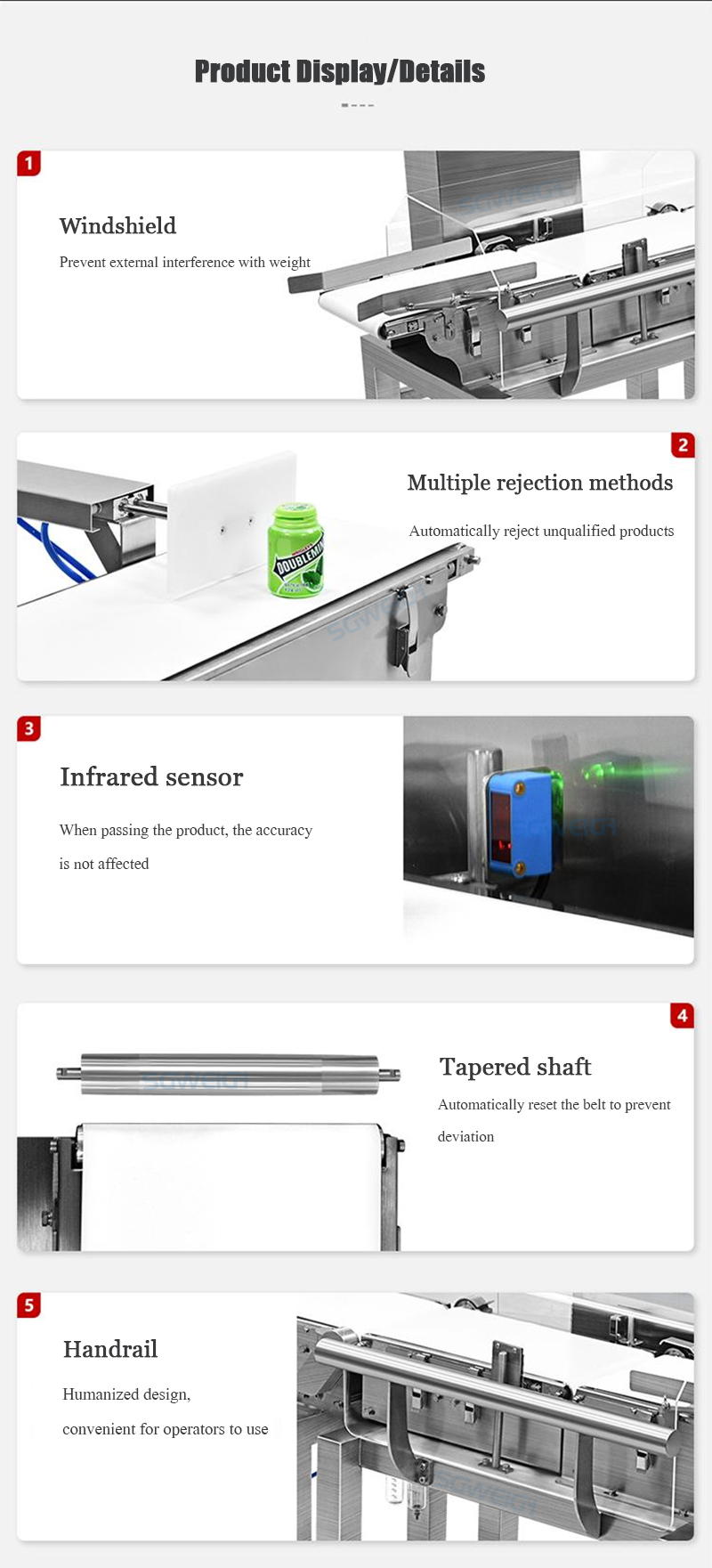

Wide range of applications: for the weight detection of bagged filling products, a variety of rejection methods can be selected (dial lever type air blowing type push can type, etc.

Automatic feedback function: It can feed back the packaging accuracy to the front-end equipment signal in time to adjust the feeding status of the connected equipment

1. Assembly line weighing detection:

1) Overweight/underweight detection; 2) FCL missing parts detection; 3) Accessories missing detection.

2. Assembly line weighing sorting:

1) multi-stage weight sorting; 2) substandard product sorting; 3) substandard product rejection.

3. Combined application of checkweigher machine:

Shanghai Shigan Automation provides a combination of weighing machine and metal detection, automatic coding, automatic scanning and automatic sealing equipment.

4. Customer customization:

Shanghai Shigan Automation provides specialized customized solutions and equipment based on the actual testing needs of enterprise users and the characteristics of the production environment.

Shanghai Shigan is a manufacturer of automatic checkweigher equipment with many years of experience. It is committed to providing solutions for quality inspection on the product assembly line, so that the required inspection process can be more effectively coordinated, beautiful, and product quality improved. At the same time, the detection efficiency is greatly improved, and the productivity of industrialization is improved in an energy-saving manner.

Based on the business tenet of providing customers with satisfactory products and services, Shanghai Henggang Instrument Co., Ltd. solemnly promises: While ensuring the reliability and stability of the instrument, it will continue to improve the quality of service, from in-sale to after-sale delivery, Commissioning, instrument maintenance and management, technical services, user technical training and other aspects, to ensure that customers can receive caring services, so that customers are satisfied and assured.

1. Ensure that the instrument packaging meets the requirements of moisture, rain, rust, corrosion, and shock resistance, and the identification is clear and correct, so that the goods can be delivered to the site safely and in time.

2. High-quality and fast technical services

In order to better ensure the normal operation of the instrument, answer questions raised by users in a timely manner, and help users solve problems, the company's maintenance center is responsible for providing customers with free technical consulting services at any time.

The company's maintenance center has a 24-hour call service, and a full-time engineer accepts calls from users to ensure that users receive timely technical support during the use of the instrument.

Related Products

Automatic Checkweigher High Speed Assembly Line Packaging Checkweigher

High Speed Bottled Checkweigher Industry Checkweigher Conveyor System Manufacturer

Checkweigher for Facial Mask-Flake Cosmetics High Accuracy Food Checkweigher

10kg High Quality Checkweigher Conveyor Manufacturer Chemical Industry Checkweigher-Automatic Weighing Scale

Large Range Automatic Checkweigher Customization Food Seafood Checkweigher and Metal Detector

Hot Labels:checkweigher,high precision checkweigher,daily necessities check weight machine,5kg checkweigher,customized machine,supplier,manufacturer

Equipped with advanced load ce...

View MoreThis industrial spray bottle c...

View MoreThis multi-lane checkweigher f...

View MoreThe multi-lane checkweigher fo...

View MoreThe box check weigher with met...

View MoreThe digital soft gel capsules ...

View More