The packaged chemical industry products pass the checkweigher weighing test, the qualified ones will be sent back to the original conveyor belt, the unqualified ones will be rejected (or alarm shutdown), and the products are classified and counted according to the settings, and the feedback signal is automatically provided to adjust and correct the feeding equipment , Text display fault alarm information, multiple graphic statistics display and other functions.

The packaged products pass the chemical industry checkweigher weighing test, the qualified ones will be sent back to the original conveyor belt, the unqualified ones will be rejected (or alarm shutdown), and the products are classified and counted according to the settings, and the feedback signal is automatically provided to adjust and correct the feeding equipment , Text display fault alarm information, multiple graphic statistics display and other functions.It can save manpower, improve efficiency, avoid unnecessary loss due to excessive packaging or customer complaints due to insufficient weight, so as to improve customer satisfaction. Automatic weighing scale is a quality inspection equipment for automatic production lines and packaging lines.Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

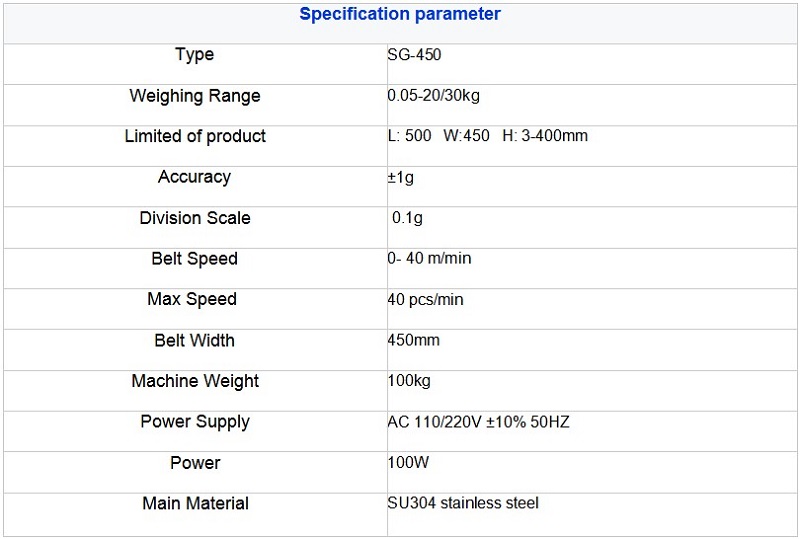

Note 1: The above specifications are standard specifications, other sizes can be customized according to customer needs.

Note 2: The above detection sensitivity is the surface accuracy of the empty conveyor belt. The actual detection sensitivity is affected by the product to be tested, the use environment, or the location of the metal mixing.

■Rejection method: alarm/stop/push rod type (optional)

◆Equipment material: stainless steel/carbon steel paint (high-gloss white)

■Optional configuration:

◆The front automatic separation conveyor line, the way of rejecting unqualified products.

■Optional customization:

◆ Various weights and sizes of checkweighers can be customized according to customer requirements.

■Note:

◆There should be a relative interval between two products during continuous checkweighing to ensure that only one product is on the weighing platform at a uniform time

◆The button adopts the design of tactile feeling, and the back glue adopts 3M glue sticker for waterproof;

◆Optional RS232/485 interface, which can be connected to PC and printer; large subtitles can be purchased.

◆ The instrument is small in size and light in weight, very suitable for portable use.

◆ Backlit display, clearly visible during the day and night.

◆ There is a perpetual calendar clock inside.

◆Multi-language display: 7-inch full Chinese color LCD screen, full guidance operation, intelligent alarm display;

◆Intelligent efficiency: Chinese touch interface, multi-group formula storage, password authority management, Chinese weighing record, intelligent fault detection, etc.;

◆Easy to operate: touch-sensitive start/stop button

◆Function switching: optional parking check weighing or continuous weighing, stop alarm or automatically reject when abnormal;

◆System protection: the system sets zero zone protection;

◆Control system: PLC control loop, special software for checkweigher.

◆Suitable for heavy product inspection in assembly line;

◆The automatic checkweigher is equipped with two-color indicator lights red and green, respectively representing overweight, underlight and moderate;

◆When the weight is OK, the green light is displayed, and the product will pass automatically;

◆When the weight is HI or LO, the red light is displayed, and the product will be judged as unqualified and automatically rejected;

◆The instrument adopts all Chinese interface mode, the interface design is humanized, and the operation is convenient;

◆The detection weight range can be set arbitrarily;

◆The upper and lower limit weight parameters can be set arbitrarily.

Shanghai Shigan Industrial Co., Ltd. is a professional supplier of assembly line weighing equipment and production line automation equipment, providing technical services, technology development, technical consultation and professional automatic checkweigher equipment for different packaging industries! Products mainly cover pharmaceutical, food, health products, daily chemical, battery, light industry and other industries!

Shanghai Shigan after-sales service commitment:

Based on the spirit of pursuing high-quality products and customer satisfaction, Shanghai Shigan Company solemnly promises you with the principles of preferential prices, considerate service and reliable product quality.

1.Product quality commitment:

(1). The manufacturing and testing of products have quality records and testing data.

(2). For product performance testing, we sincerely invite users to personally check the whole process and performance of the product. After the product is confirmed qualified, it will be packed and shipped.

2. Product price commitment:

(1). Under the same competitive conditions, our company will sincerely provide you with preferential prices on the basis of not reducing product technical performance or changing product components.

3. Delivery time commitment:

(1). Product delivery time: try to meet user requirements, if there are special requirements, need to be completed in advance, and strive to meet user needs.

Related Products

Roller Scale With Three-color Warning Light

10kg High Quality Checkweigher Conveyor

Checkweigher for Daily Necessities Below 5kg

Metal Detector for Aluminum Foil

Checkweigher for Facial Mask-Flake Cosmetics

Large Capacity Weighing and Filling Machine

Hot Labels:chemical,industry,checkweigher,automatic checkweigher, weighing scale,manufacturer,supplier,price,customized

The rotary checkweigher for be...

View MoreThis pharmaceutical packaging ...

View MoreThis dual-lane checkweigher fo...

View MoreThis high-speed bottle weighin...

View MoreThis daily necessities packagi...

View MoreThis online weight checker for...

View More