The box check weigher with metal detector combo is integrated into one unit, allowing the product to pass these two inspection processes seamlessly, with high precision, fast detection, high adaptability and intelligent automatic control, which meets the needs of modern industrial production. The high-precision check weigher with metal detector combo provides a comprehensive solution for product inspection, ensuring weight compliance and metal contamination detection in a single integrated unit.

SG-JS150 High-precision Conveyor Box Check Weigher With Metal Detector Combo

The box check weigher with metal detector combo is integrated into one unit, allowing the product to pass these two inspection processes seamlessly, with high precision, fast detection, high adaptability and intelligent automatic control, which meets the needs of modern industrial production. The high-precision check weigher with metal detector combo provides a comprehensive solution for product inspection, ensuring weight compliance and metal contamination detection in a single integrated unit. For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

Box check weigher with metal detector combo pictures

1. New box check weigher with metal detector combo system can upgrade your entire production line:

Food safety and quality have been upgraded simultaneously. So, why only use new technology in some parts of your product inspection solution and old technology in other parts? The new combined system allows you to enjoy both technologies at the same time, improving your brand protection capabilities.

2. Combination can save space:

Floor space and line length can be very important factors in a typical food processing facility. Installing a box check weigher with metal detector combo on the same conveyor can save up to 50% more floor space than two separate systems.

3. Combinations are easier to use:

Communication between the box check weigher with metal detector combo, including setup, program management, statistics, alarms and rejects, can be managed from a single controller, making it easier to use.

4. The combination offers excellent value:

A truly integrated combination shares hardware, resulting in significant savings compared to purchasing separate metal detectors and checkweighers.

5. The combination is easier to maintain/repair:

The combination is designed to operate as one system, making troubleshooting easier and faster. A single point of contact also means you can have factory-trained field service engineers diagnose issues with your entire system, maximizing equipment uptime.

High-precision Conveyor Box Check Weigher With Metal Detector Combo

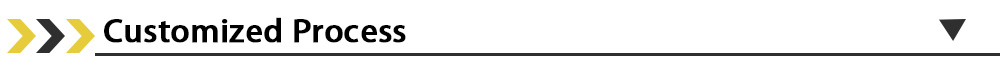

Customized support: OEM, ODM

Place of Origin: China

Brand Name: SHIGAN

Rated power: 0.4KW

Single weighing range: ≤40KG

Accuracy: ±5G~±30G

Conveying speed: 20~35m/Minute

Belt size: 1200mm(L)600mm(W)

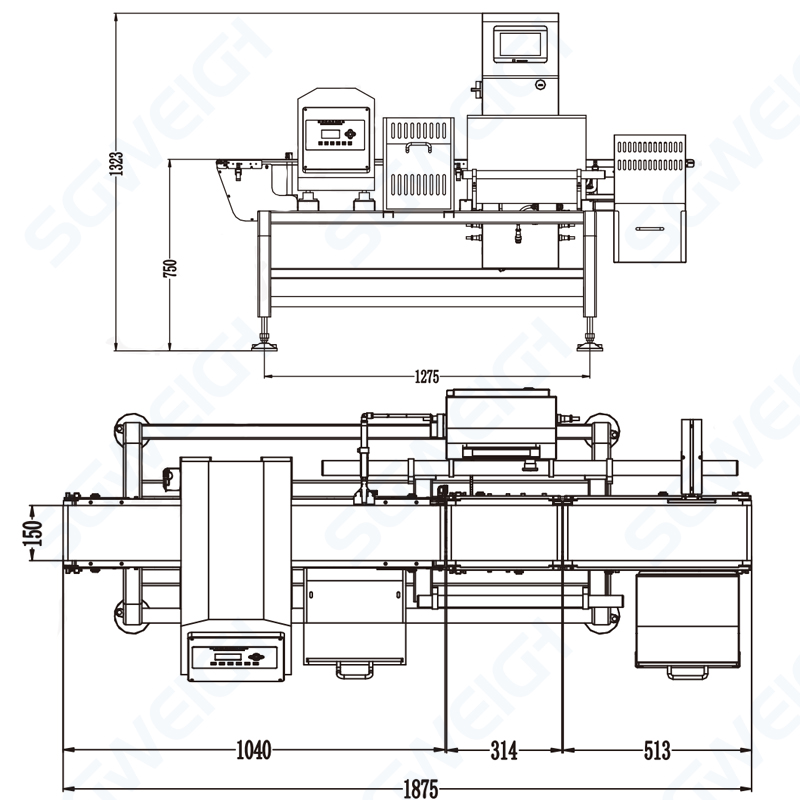

Product size: 1888mm(L)*935mm(W)*1060mm(H)

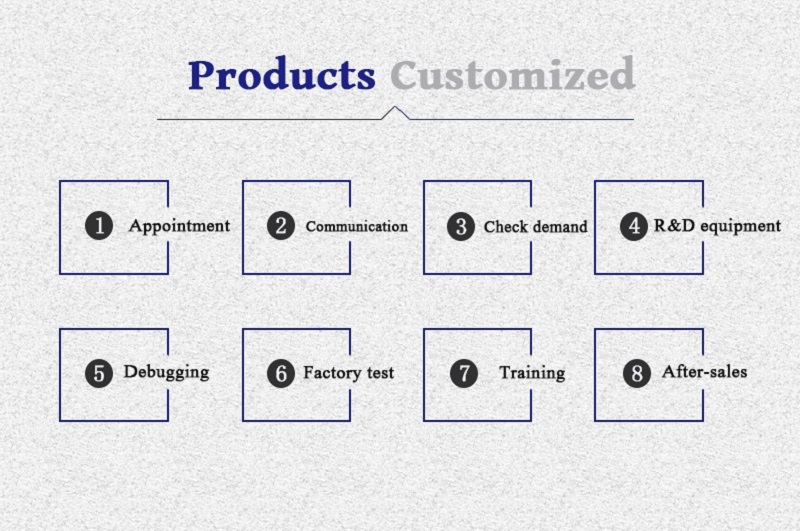

Removal method:Push-rod

Fuselage material: 304 Stainless Steel

Working temp: 0°~40°&30%~95%

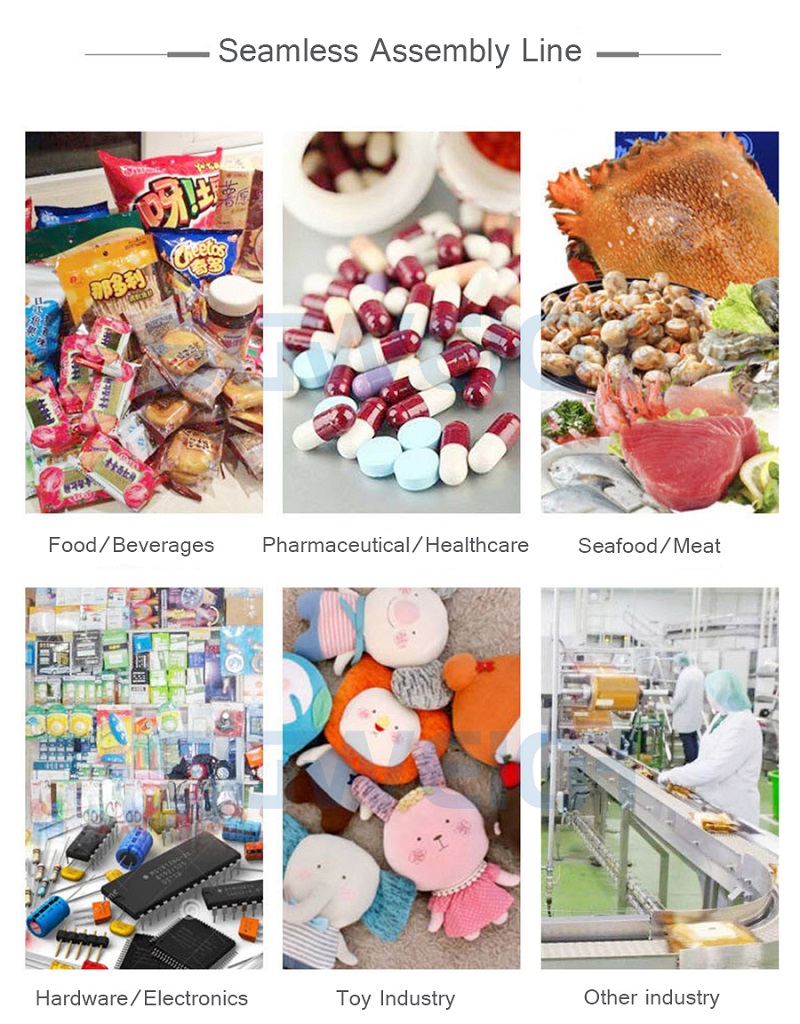

High-precision check weigher with metal detector combo is mainly used in food, medicine, packaging, printing, logistics equipment, IT digital, home appliances, stationery and toys, precision manufacturing, agricultural product processing and other industries to detect stainless steel, copper, aluminum, iron and other metal foreign bodies and online weight detection

1. Choose from a variety of metal detector models to optimize system size, sensitivity and price

2. Multiple checkweigher conveyor widths and lengths to meet production line needs

3. Dual rejectors separate foreign material from overweight/underweight material to help identify root cause and appropriate action

High-precision Conveyor Box Check Weigher With Metal Detector Combo

1. Packaging materials: Usually international standard export packaging boxes are used, which have good wear resistance, shock resistance and waterproof performance. The box material can be hard wooden boxes, plastic boxes or export-specific cartons.

2. Protective measures: To ensure that the machine is not damaged during transportation, it is necessary to add sufficient filling materials such as foam, shockproof cotton, etc. in the packaging box.

1. Equipment installation and commissioning: The company provides a detailed operation manual and free operation training to ensure that customers can use the equipment proficiently.

2. Technical support: The company provides 24-hour technical support to help customers solve problems encountered during use.

3. Accessories supply: The company provides original accessories to ensure the quality and stability of accessories.

4. Quality assurance: The company is responsible for the products sold and ensures that the quality and performance of the equipment meet industry standards.

5. Warranty policy: One-year warranty and lifetime maintenance to solve worries for customers.

Related Products

Auto Cream Sauce Filling Multi-lane Packaging Machine

Efficiency Hardware Dynamic Weighing Checkweigher

Medicine Plastic Bottle Weighing Check Weigher

Capsules Tablets Throat Metal Detector

Weighing Conveyer Check Weigher for Rubber Industry

Health Care Liquid Sachet Multi-lane Packing Machine

Soft Gel Capsules Tablets Metal Detector

Corn Multi-level Sorting Check Weigher

Checkweigher With Metal Detector System for Box Bottle

Hot Labels: high-precision,conveyor,box,check weigher with metal detector combo,manufacturer,supplier,factory,price

The multi-lane checkweigher fo...

View MoreThe box check weigher with met...

View MoreThe digital soft gel capsules ...

View MoreThis capsule tablet checkweigh...

View MoreShampoo bag multi-lane checkwe...

View MoreBottle rotary weighing checkwe...

View More