The conveyor belt checkweigher is suitable for product net weight detection/full box missing parts detection/missing package detection, weight checker is embedded in the production line, each product is fully checked and NG products are automatically rejected, automatic weighing machine ±0.2g, accurate check and re-selection of defective products.

The conveyor belt checkweigher is suitable for product net weight detection/full box missing parts detection/missing package detection, automatic check weight machine is embedded in the production line, each product is fully checked and NG products are automatically rejected, automatic weighing machine ±0.2g, accurate check and re-selection of defective products.Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

Type SG-400

Restrictions of product 10-10000g

Accuracy L:450 W:400 H:3-400mm

Division Scale ±1-10g(Depends on products)

Belt speed 1g

Highest speed 0-60m/min

Belt Width 50pcs/min

Weight of Machine 400mm

Weight of Machine 80Kg+44Kg

Power Supply AC 220V±10%50HZ

Power About 300W

Main Material SUS304 Stainless Steel

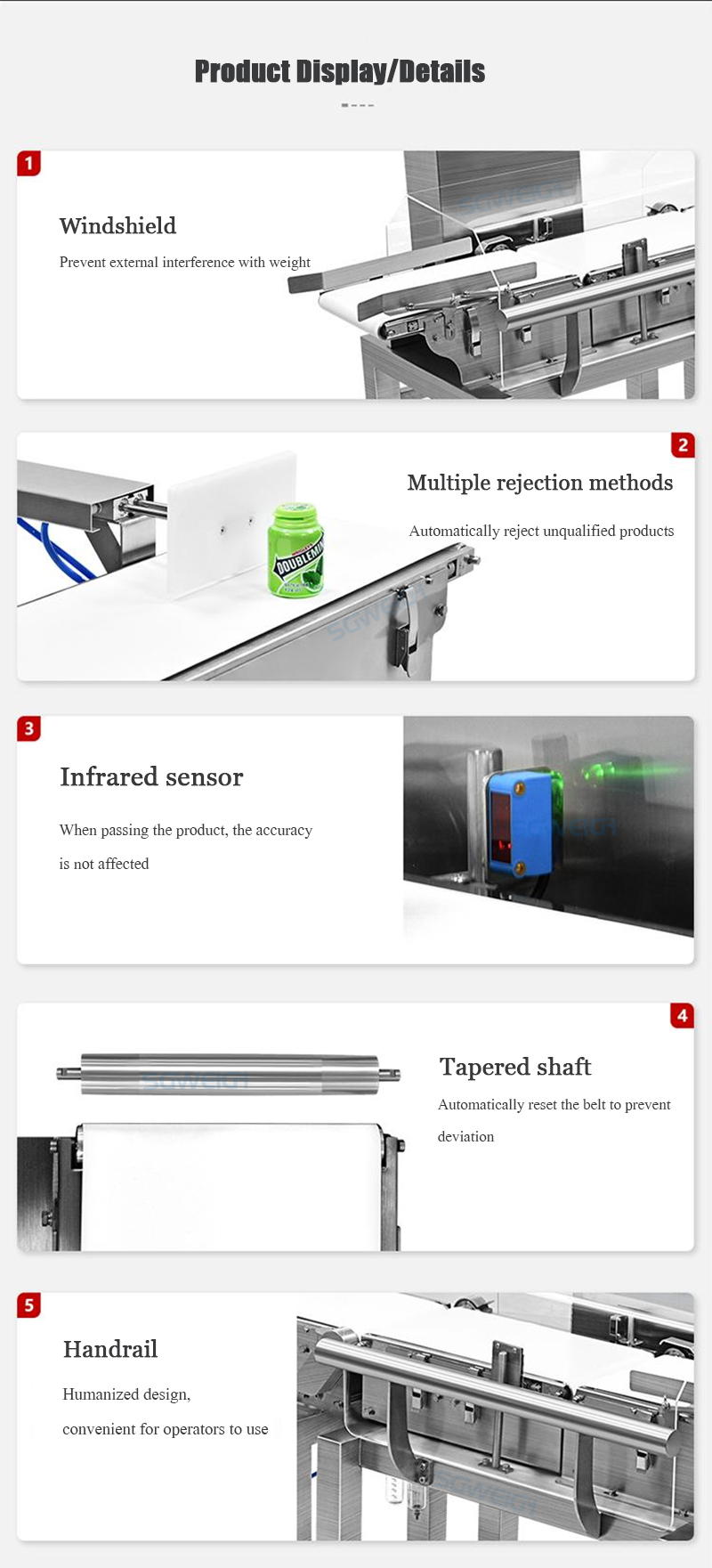

1) The automatic checkweigher can be embedded in the user assembly line to automatically weigh and detect each product to achieve full product inspection;

2) The range of the inline check weigher supports free setting, and the abnormal quality type can be set to automatically reject defective products;

3) The weight checker adopts the HBM weighing module imported from Germany to continuously and accurately weigh;

4) Automatic dynamic weight compensation technology, automatic zero tracking and zero clearing processing technology;

5) The digital checkweigher supports multiple communication protocol interfaces, supports report export, and facilitates production data management;

6) The high quality check weigher has its own fault detection function and automatic protection function when power is off;

7) Support storage of 100 kinds of detection formulas, which can be called, modified and used at any time;

8) The speed of the automatic checkweigher can be adjusted by frequency conversion, which can flexibly match the production line speed;

9) Support full-function customization service of checkweigher to ensure that it fully matches the needs of assembly line weighing equipment.

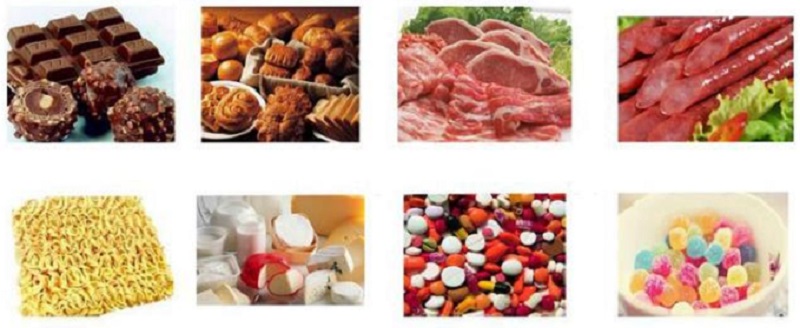

Convetor belt checkweigher is widely used in online high-speed packaging checkweighing applications in pharmaceutical, food, health care, daily chemical, battery, light industry and other industries.

As a manufacturer of automatic checkweighing scales, Shanghai Shigan Industrial Co., Ltd. has more than ten years of industry experience and provides reference for multiple sets of free packaging solutions. Since its establishment, the company has been engaged in the R&D, design, manufacturing, installation, commissioning and technology of assembly line testing packaging and supporting equipment Service, with technology as the core, flexibly improve the production design of the checkweigher according to the actual product needs and investment status of customers, in a true sense to meet the actual needs of customers, and greatly improve customer production efficiency.

After-sales service commitment guarantee:

Over the years, our company has continued to innovate and improve after-sales service. It has always been based on the idea of serving customers as the core, providing users with stable and high-quality projects, while adhering to the purpose of "pursuing excellence and moving into the future". Good after-sales service makes customers feel relieved to buy and use happily. Good products in the world require follow-up after-sales service. In order to eliminate customers' concerns about future maintenance of products, our company solemnly makes the following commitments regarding after-sales service.

1. The customer will have a free warranty within one year from the date of acceptance, and will be responsible for lifelong maintenance.

2. Answer all questions and answers to customers' calls, and achieve high-quality service of "one call to do it right away".

3. Establish a customer after-sales service special person responsible system, each time the service is completed, the after-sales service form must be filled in and the customer signed and approved the file and save it.

4. Warm and serious reception of visiting customers, and deal with related matters in a short time until the customers are satisfied.

Related Products

Automatic Checkweigher Checkweigher

High Speed Bottled Checkweigher High Speed Assembly Line Packaging Checkweigher

Checkweigher for Facial Mask-Flake Cosmetics Industry Checkweigher Conveyor System Manufacturer

High Accuracy Food Checkweigher Chemical Industry Checkweigher-Automatic Weighing Scale

Large Range Automatic Checkweigher Customization Food Seafood Checkweigher and Metal Detector

Hot Labels:10kg checkweigher,high quality check weigher,checkweigher conveyor,manufacturer,supplier,price

Equipped with advanced load ce...

View MoreThis industrial spray bottle c...

View MoreThis multi-lane checkweigher f...

View MoreThe multi-lane checkweigher fo...

View MoreThe box check weigher with met...

View MoreThe digital soft gel capsules ...

View More