The automatic weighing detection and automatic rejection of non-conforming products during the production process of small packaging products for high speed checkweigher produced by Shanghai Shigan ensure that the weight of each product meets the quality requirements of industry production, industry, users, regulations, etc., and is the current product one of the key testing and quality control methods for quality control.

The automatic weighing detection and automatic rejection of non-conforming products during the production process of small packaging products for high speed checkweigher produced by Shanghai Shigan ensure that the weight of each product meets the quality requirements of industry production, industry, users, regulations, etc., and is the current product one of the key testing and quality control methods for quality control.The assembly line packaging checkweigher can ensure the user's daily chemical, food, completeness and quality inspection rate, avoiding fines and quality complaints.For further information about our services, or if you would like one of our professionals to contact you, please contact us.

Type SG-100

Weighing Range 2-300g

Limited of product L: 100 W: 100 H: 2-150mm

Accuracy ±0.5g Depends on product

Division Scale 0.01g

Belt Speed 0- 80 m/min

Max Speed 300 pcs/min

Belt Width 100mm

Machine Weight 60kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

Main performance characteristics of checkweigher

1) The high speed checkweigher is embedded in the user assembly line to automatically weigh and detect each product to achieve full product inspection;

2) The weight detection range of the inline checkweigher can be set freely, and the abnormal quality type can be set to automatically reject defective products;

3) The assembly line checkweigher adopts the HBM weighing module imported from Germany to continuously weigh accurately and dynamically;

4) Automatic dynamic weight compensation technology, automatic zero tracking and zero clearing processing technology;

5) The dynamic checkweigher supports multiple communication protocol interfaces, supports report export, and facilitates production data management;

6) The automatic checkweigher has its own fault detection function and automatic power-off protection function;

7) Support storage of 100 kinds of detection formulas, which can be called, modified and used at any time;

8) The speed of the online automatic checkweigher can be adjusted by frequency conversion, which can flexibly match the production line speed;

9) Support full-featured customized service of checkweigher to ensure that it fully matches the design of assembly line weighing

1.Unqualified detection of net content of packaged products-product underweight detection

2.Lack of single product quantity detection-missing parts/missing pieces/missing packages/missing cans/missing bottles, etc.

3.Lack of packaging accessories detection-product integrity testing such as missing/less packaging of accessories

Shanghai Shigan Industrial Co., Ltd. was established in 2010 and is located in Shanghai, China. It is a high-tech enterprise specializing in R&D, production and sales of testing equipment. A technical team with independent research and development capabilities has been formed to ensure that the company can continuously launch new products that meet customer needs. The product quality is trusted by users and has won praise from customers in domestic and foreign markets. The products have passed the EU CE certification and are sold throughout the country and exported to many foreign countries and regions.

The company can customize various specifications of testing equipment according to the special requirements of customers, and can carry out engineering design and installation according to the characteristics of the customer's production line, which can be tailor-made for customers.

1.Are you a manufacturer?

Yes, we are a professional checkweigher manufacturer with our own factory, and we also welcome you to visit our factory

2. What is the detection accuracy of your company? How fast can it be?

Answer: There are many determinants of the accuracy of testing products, which are related to the weight, size, speed and use environment of the product. In general, the greater the weight, the larger the product size, and the faster the speed, the worse the accuracy of the product detected, which is inversely proportional. The inspection speed can currently reach 300 pieces/minute.

3. How long does it take for your company's products to be delivered?

Answer: For customers who can use standard machines, our company has them in stock. After receiving the payment, they can be shipped within three working days. For non-standard equipment, due to the need to redesign and change, the delivery time is about 2-3 weeks. The company currently introduces a processing technology team to shorten the delivery time as much as possible.

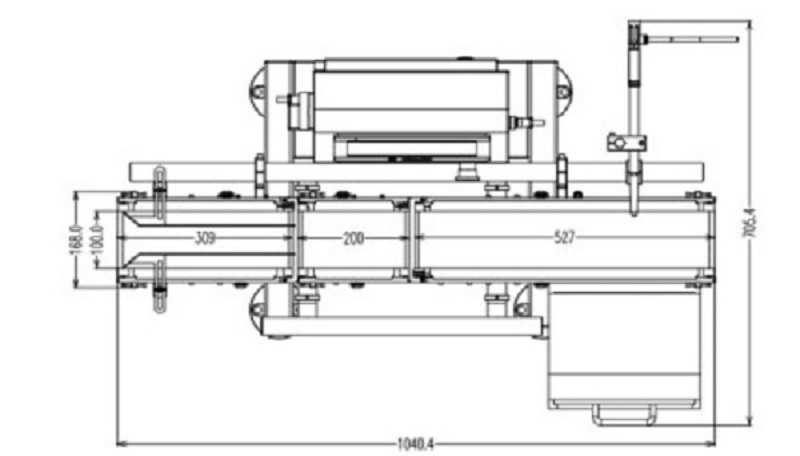

4. What are the dimensions of the product?

Answer: Our company supports product size customization, please contact technical staff for details

5. Payment method

There are many payment methods we support, such as:TT,L/C,Western Union,Money Gram,Paypal,International Credit Card.

Based on the business tenet of providing customers with satisfactory products and services, Shanghai Shigan Industrial Co., Ltd. solemnly promises: While ensuring the reliability and stability of the instrument, it will continue to improve the quality of service, from in-sale to after-sale delivery, commissioning, instrument maintenance and management, technical services, user technical training and other aspects, to ensure that customers can receive caring services, so that customers are satisfied and assured.

1. Ensure that the instrument packaging meets the requirements of moisture, rain, rust, corrosion, and shock resistance, and the identification is clear and correct, so that the goods can be delivered to the site safely and in time.

2. High-quality and fast technical services

In order to better ensure the normal operation of the instrument, answer questions raised by users in a timely manner, and help users solve problems, the company's maintenance center is responsible for providing customers with free technical consulting services at any time.

The company's maintenance center has a 24-hour call service, and a full-time engineer accepts incoming calls from users to ensure that users receive timely technical support in the process of using the instrument.

Related Products

SG-150H High Speed Bottled Checkweigher

SG-220 Industry Checkweigher Conveyor System

SG-300 High Precision Checkweigher for Daily Necessities

SG-400 10kg High Quality Checkweigher Conveyor

SG-JS220 Food Seafood Checkweigher and Metal Detector

Hot Labels:checkwiegher,high speed,automatic,assembly line,check weight machine,supplier,customized

Equipped with advanced load ce...

View MoreThis industrial spray bottle c...

View MoreThis multi-lane checkweigher f...

View MoreThe multi-lane checkweigher fo...

View MoreThe box check weigher with met...

View MoreThe digital soft gel capsules ...

View More