Food metal detectors are used to detect any metal impurities in powdered and granular products, such as iron, copper, stainless steel, aluminum and all other metals. Metal detection machine can be used to detect raw materials, semi-finished products, cost and other products, and can also be used for pre-production, in-production, and post-production testing.

Food metal detectors are used to detect any metal impurities in powdered and granular products, such as iron, copper, stainless steel, aluminum and all other metals. Metal detection machine can be used to detect raw materials, semi-finished products, cost and other products, and can also be used for pre-production, in-production, and post-production testing.Please feel free to contact us if you have any needs.

Ps:

1.The above sensitivity is empty machine detection sensitivity, the actual sensitivity should exist. Product effects will vary according to different products.

2.The size is for reference only and can be customized

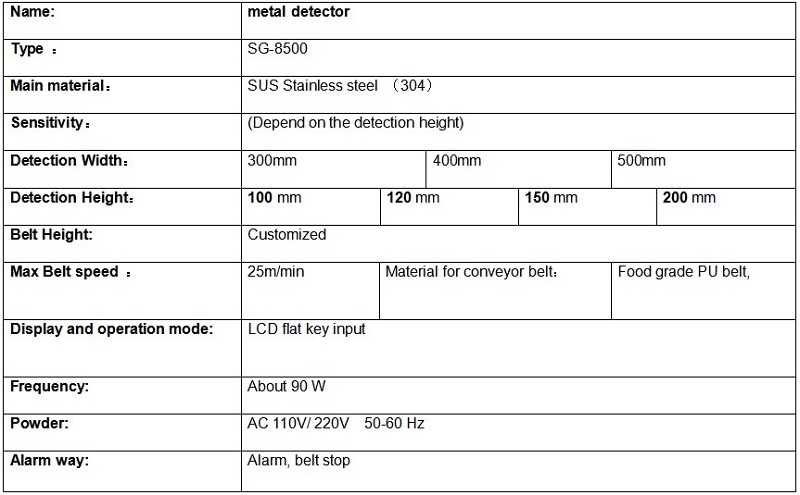

Display operation mode: LCD color screen, panel operation

Product configuration quantity: 100 kinds

The packaging form of the tested product: non-metal packaging, plastic bag, paper bag, carton, etc., both bulk materials

Conveyor belt type: food grade PVC belt (PU belt is optional)

Transmission speed: fixed speed 27m/min (other speeds can be customized, 5~40m/min), if you need to adjust the speed, you can choose a speed controller, frequency conversion speed control

Alarm elimination method: alarm to stop, or alarm and automatically eliminate (alarm lamp, elimination device optional)

1.The double loop electromagnetic wave detection, the new analog circuit and the digital circuit combination, greatly improve the reliability and intelligence of the product.

2.It adopts a new type of touch screen input and a large-scale integrated circuit. The CPU completes the collection of analog signals and converts them into digital quantities for processing and output, automatically collecting the best points of the metal content of the detected objects, greatly improving the sensitivity and reliability of detection.

3.Adopting humanized interface design, the entire operation process is simple and intuitive, the man-machine interface is clear at a glance, and all functions can be operated directly on the screen to complete the executed functions.

4.You can set various required functions and modes, and set up a self-check function.

5.Sensitivity can be adjusted to increase or decrease (1-9 gears adjustable).

6.When trace metal is detected, sound, light, and instrument will alarm at the same time, and the machine will stop or kick out unqualified products.

7.This product uses a computer to form a control system. According to the special requirements of the user, it can complete the number of detections, the classification statistics of qualified products, non-conforming products, data storage and printing, dry and wet concentration product identification, and mutual interference caused by multiple devices working simultaneously Separation and other requirements.

Food digital metal detector is suitable for all kinds of food packaging products, such as: aquatic products, meat, chocolate, biscuits, sausages, quick-frozen products, candy, etc.

The company has been focusing on the development and sales of metal detection equipment and weight sorting equipment for more than ten years. It has become a relatively well-known professional testing equipment manufacturer and service provider in the industry. The company attaches great importance to independent research and development ability training and technical team construction, and has formed A technical team with independent research and development capabilities ensures that the company can continuously launch new products that meet customer needs.

The company always adheres to the production, sales and service concept of "providing customers with precise customized metal detection equipment", resolutely takes meeting customer needs as the primary goal, and strives to provide customers with professional services and qualified products. To this end, we have begun to establish a nationwide marketing service network, aiming to provide customers with thoughtful and timely services.

1. What is a metal detector and how does it work?

The metal detector is an instrument used to detect metal impurities. Usually, a metal detector is composed of a transmitter and a receiving sensor. When metal passes through the electromagnetic field generated by the transmitter, the signal received on the receiving sensor will change. The electronic components in the metal detector "see" this change and "judge" whether the change is caused by metal. If metal is found, perform corresponding alarm or elimination actions.

2. What is the use of metal detection for you?

There are usually two reasons for using metal detectors.

(1) Protect your valuable equipment or key equipment

(2) Make sure your product is perfect

3. Where should the metal detector be installed?

If the purpose of using a metal detector is to protect your equipment, you should install the metal detector as close as possible to the entrance of the protected equipment, but leave enough space for the metal detector to detect When reaching the metal, it can stop before the metal enters the equipment.

If the metal detector is used to inspect your final product, then the detector should be installed at the end of the production line as much as possible. In this way, the possibility of metal being mixed in the packaging is theoretically avoided.

4.What factors affect the sensitivity?

The sensitivity of a metal detector is determined by many factors: product effects, the shape, size and direction of metal impurities, the size of the probe, and the operating environment.

5.What should I do after detecting metal?

Many metal detectors are equipped with automatic elimination devices, which can automatically remove products containing metal impurities from the production line when the metal is detected. This can help collect and verify where these metal impurities come from. The shedding of small pieces of metal is a precursor to a big problem. If there is no automatic removal device, the product containing metal impurities should be removed manually. Also find the source of the metal and analyze the reason.

Shanghai Shigan Service:

Shigan service principle: Shigan’s electronic scale products have a warranty period of 12 months. During the warranty period, the supplier will repair and replace parts damaged due to quality reasons free of charge. Damage to parts outside the warranty period will be provided The accessories only charge cost, and the equipment damage caused by the demander's human factors, the accessories repaired or provided by the supplier are calculated at the cost price.

Shigan service goal: service quality to win customer satisfaction,

Shigan's service tenet: fast, decisive, accurate, thoughtful and thorough

Related Products

Digital Metal Detector Pharmaceutical Metal Detector Conveyor Supplier

Metal Detector for Aluminum Foil Packaging Products Metal Detector-Biscuit Detection

Food Seafood Checkweigher and Metal Detector Automatic Checkweigher With Metal Detector System

Metal Detector for Tissue Paper Products

Hot Labels:food metal detector,metal detection machine,best,sale,supplier,manufacturer,customized

High-Sensitivity Compact Metal...

View MoreThis compact checkweigher for ...

View MoreThis high-precision industrial...

View MoreThis high speed liquid stick m...

View MoreThe dynamic multi-stage weight...

View MoreThis lightweight sachet checkw...

View More