The food industry checkweigher is a high speed, high accurcay online checkweighing equipment. The high accuracy checkweigher has an advanced dynamic weight signal processing system, and a wealth of software, electronics, and mechanical options. This series of high-speed checkweighers can meet online checkweighing requirements for the food industry.

The food industry checkweigher is a high speed, high accurcay online checkweighing equipment. The high accuracy checkweigher has an advanced dynamic weight signal processing system, and a wealth of software, electronics, and mechanical options. This series of high-speed checkweighers can meet online checkweighing requirements for the food industry.If you want to know more,please contact me!

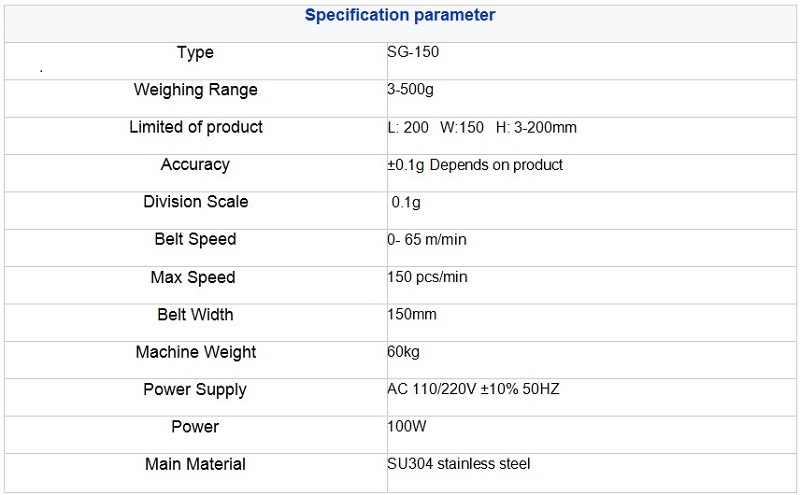

Remarks:

The highest checkweighing capacity and accuracy of the checkweigher vary according to the actual product being tested, the selection part and the application environment

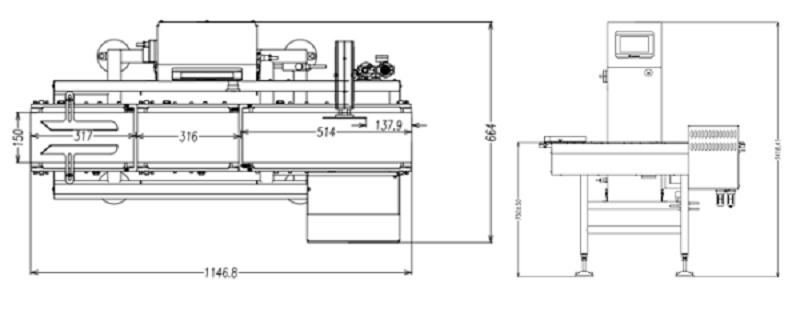

The size is for reference only and can be customized

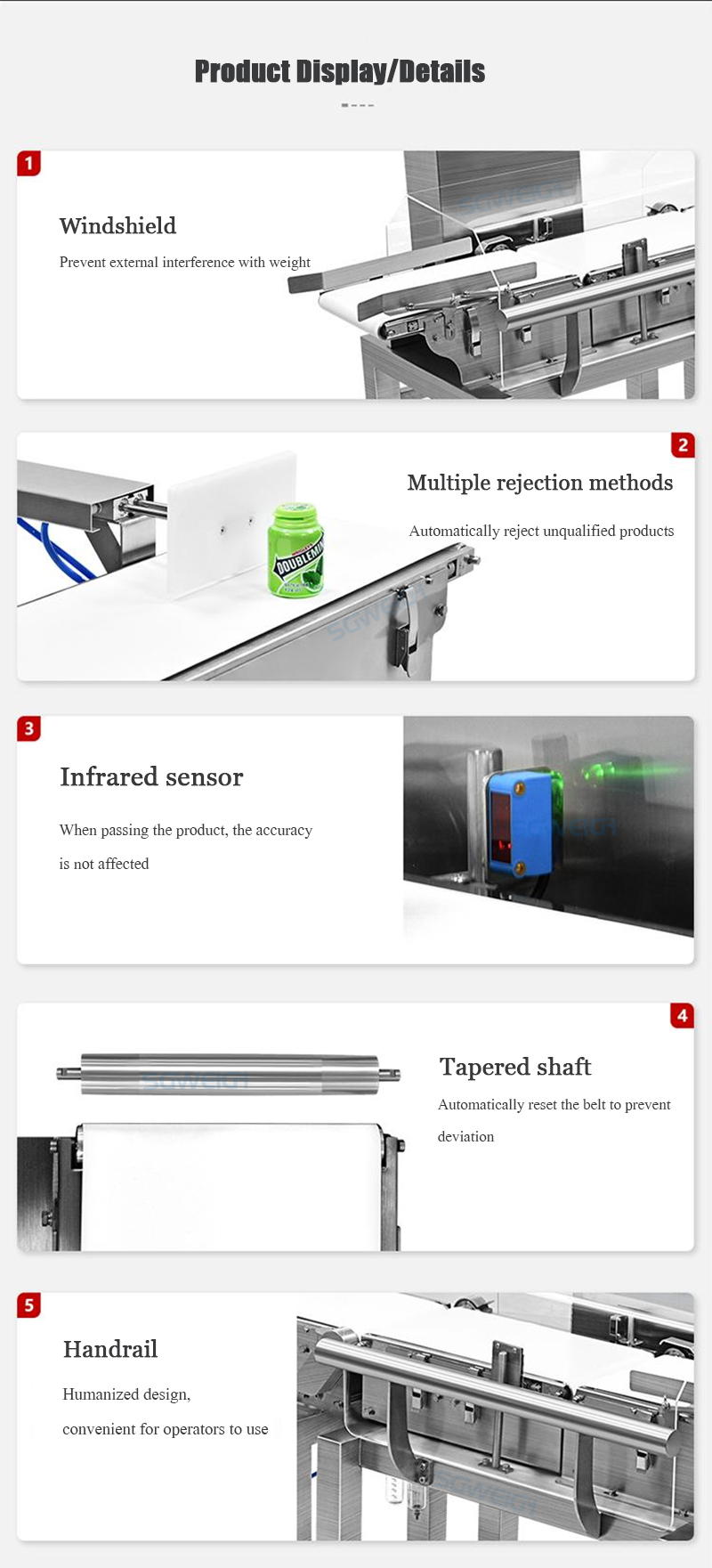

1) The assembly line dynamic checkweigher is embedded in the user assembly line to automatically weigh and inspect each product to achieve full product inspection;

2) The weight detection range of the automatic check weigher supports free setting, and the abnormal quality type can be set to automatically reject defective products;

3) The weight checker adopts the HBM weighing module imported from Germany to continuously and accurately weigh;

4) Automatic dynamic weight compensation technology, automatic zero tracking and zero clearing processing technology;

5) The checkweigher supports multiple communication protocol interfaces, supports report export, and facilitates production data management;

6) The checkweigher has its own fault detection function and automatic power-off protection function;

7) Support storage of 100 kinds of detection formulas, which can be recalled, modified and used at any time;

8) The speed of the automatic checkweigher can be adjusted by frequency conversion, which can flexibly match the speed of the production line;

9) Support full-function customization service of drug checkweigher to ensure that it fully matches the needs of assembly line weighing equipment.

The high accuracy checkweigher is suitable for testing whether the weight of a single product is qualified, and is widely used in many industries such as electronics, pharmaceuticals, food, beverages, health care products, daily chemicals, light industry, and agricultural and sideline products. Such as prepared products, cakes, ham sausages, instant noodles, frozen foods, food additives, pigments, modifiers, preservatives, etc. in the food industry.

Shanghai Shigan Industrial Co., Ltd. was established in 2010. The company has been focusing on the development and sales of automatic checkweighers, metal detectors, assembly line packaging machines and other equipment for more than ten years. It has become a well-known professional testing equipment manufacturer and service provider in the industry , The main products are a series of assembly line testing equipment such as automatic checkweigher, digital metal detector, automatic packaging machine, premade pouch packaging machine, roller scale, etc.

In line with the business tenet of "providing customers with satisfactory products and services", Shanghai Shigan Industrial Co., Ltd. solemnly promises: While ensuring the advanced nature, reliability and stability of the equipment, it will continue to improve the quality of service, from sale to After-sales delivery, commissioning, equipment maintenance and management, technical services, user technical training, etc., ensure that customers can get good services and make customers satisfied and assured.

1. Ensure that the equipment packaging meets the requirements of moisture-proof, rain-proof, rust-proof, anti-corrosion and shock-proof, and the identification is clear and correct, so that the goods can be delivered to the site safely and in time.

2. High-quality and fast technical services

In order to better ensure the normal operation of the equipment, answer questions raised by users in a timely manner, and help users solve problems, the company's maintenance center and local maintenance outlets are responsible for the opening, maintenance and technical consulting services in each region. In the maintenance center, a full-time engineer is responsible for providing customers with free technical consulting services at any time.

The company's maintenance center has a 24-hour call service, and a full-time engineer accepts incoming calls from users to ensure that users receive timely technical support in the process of using the equipment.

3. Free debugging and activation for users, and responsible for the training of operators.

Related Products

Automatic Checkweigher High Speed Assembly Line Packaging Checkweigher

High Speed Bottled Checkweigher Industry Checkweigher Conveyor System Manufacturer

Checkweigher for Facial Mask-Flake Cosmetics High Precision Checkweigher for Daily Necessities Below 5kg

10kg High Quality Checkweigher Conveyor Manufacturer Chemical Industry Checkweigher-Automatic Weighing Scale

Large Range Automatic Checkweigher Customization Food Seafood Checkweigher and Metal Detector

Hot Labels:high accuracy checkweigher,food checkweigher,check weight machine,customized,checkweigher manufacturer,supplier,price

This pharma bottle checkweighe...

View MoreThis metal detector + weight c...

View MoreLeveraging advanced load cell ...

View MoreThis auto checkweigher with du...

View MoreThis inline metal detector for...

View MoreThis sensitivity metal detecto...

View More