The express sorting checkweigher detects the weight of the product on the production line with a high-speed dynamic weight reading method. It can detect the unqualified products in the continuous production line, and execute the control of the upper and lower line discrimination or automatic weight sorting according to this. , Especially suitable for the inspection of missing parts in food packaging products.

Products Description

The express sorting checkweigher detects the weight of the product on the production line with a high-speed dynamic weight reading method. It can detect the unqualified products in the continuous production line, and execute the control of the upper and lower line discrimination or automatic weight sorting according to this. , Especially suitable for the inspection of missing parts in food packaging products. The packaged products pass the intelligent automatic checkweigher weighing test, the qualified ones will be sent back to the original conveyor belt, the unqualified ones will be rejected (or alarm shutdown), and it has the functions of classifying and counting the products according to the settings.Our product specifications and sizes are rich, various styles, welcome to contact us for quotation information.

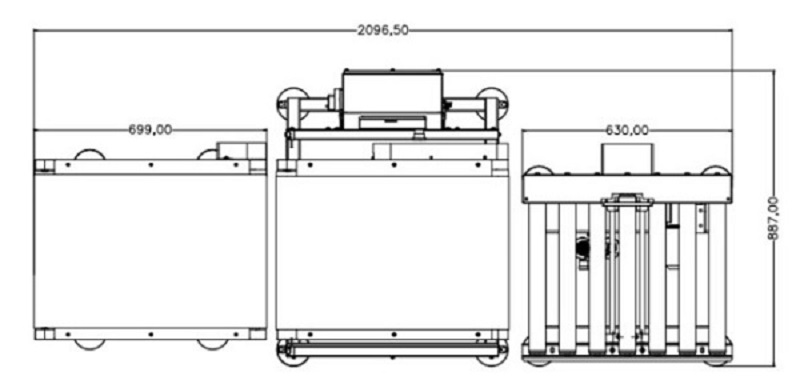

Specification Parameter

Type SG-450

Weighing Range 0.05-20/30kg

Limited of product L: 500 W:450 H: 3-400mm

Accuracy ±1g

Division Scale 0.1g

Belt Speed 0- 40 m/min

Max Speed 40 pcs/min

Belt Width 450mm

Machine Weight 100kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

Note:

1.The above accuracy is the empty test sensitivity, the actual accuracy will vary due to the product's own effects, environment, temperature and other reasons.

2.The size shown is the size of the standard model, and the size can be customized.

Main Features

1) The weight sorting checkweigher is embedded in the user assembly line to automatically weigh and detect each product to achieve full product inspection;

2) The weight detection range of the express automatic checkweigher supports free setting, and the type of abnormal quality can be set to automatically reject defective products;

3) The express scale conveyors adopts the HBM weighing module imported from Germany to continuously and accurately weigh;

4) Automatic dynamic weight compensation technology, automatic zero-point tracking and zero-clearing processing technology;

5) The intelligent checkweigher multiple communication protocol interfaces, supports report export, and facilitates production data management;

6) The express conveyor belt check weigher has its own fault detection function and automatic protection function when power is off;

7) Support 100 kinds of test formula storage, call, modify and use at any time;

8) The speed of the online express automatic checkweigher can be adjusted by frequency conversion, which can flexibly match the speed of the production line;

9) Support the full-function customization service of express sorting checkweigher to ensure that it fully matches the needs of assembly line weighing equipment.

Application

Express intelligent sorting checkweigher is widely used in online high-speed packaging checkweighing applications in pharmaceutical, food, health care, daily chemical, battery, light industry, logistics and other industries.

About Shanghai Shigan Industrial Co,. Ltd

Founded in 2010, Shanghai Shigan Co., Ltd. is a high-tech enterprise specializing in R&D, production and sales of testing equipment. The company has been focusing on the development and sales of automatic checkweighers, digital metal detection equipment, vertical packaging machines and other assembly line equipment for more than ten years. It has become a well-known professional equipment manufacturer and service provider in the industry. The main products are automatic checkweighers,digital metal detection machine, vertical packaging machines, premade pouch packaging machines, linear scales, weighing labeling machines, etc. Companies attach great importance to independent research and development ability training and technical team construction, and have formed a technical team with independent research and development capabilities,to ensure that the company can continue to introduce new products that meet customer needs.

The company can customize testing equipment of various specifications according to the special requirements of customers, and can carry out engineering design and installation according to the characteristics of the customer's production line, which can be tailor-made for customers. The quality of the company's products is trusted by users and has won praise from customers in domestic and foreign markets. The products have passed the EU CE certification and are sold throughout the country and exported to many foreign countries and regions.

After-sale Service

Shigan after-sales service commitment:

Shanghai Shigan has always pursued lofty ideas and solved all needs for customers. Our company solemnly promises you with the principle of "low price, good service, and good product quality":

⑴ Service tenet: fast, decisive, accurate, thoughtful and thorough

⑵Service goal: service quality wins customer satisfaction

⑶ Service efficiency: If the equipment fails during or outside the warranty period, after the supplier receives the notice, the maintenance personnel can reach the site and start the repair within 24 hours.

⑷Service principle: The product warranty period is twelve months. During the warranty period, the supplier will repair and replace the parts damaged due to quality reasons free of charge. If the parts are damaged outside the warranty period, only the cost will be charged for the accessories provided. For equipment damage caused by human factors on the demand side, the repair or accessories provided by the supplier shall be calculated at the cost price. After the warranty period, our company's technical staff will return visits from time to time to investigate the user's usage.

Related Products

300g Weighing Sorting and Rejecting Checkweigher Overweight / Underweight Detection Weighing Equipment

Full Box Detection Automatic Checkweigher Assembly Line Terminal Test Scale Checkweigher

High Speed Bottle Automatic Checkweigher Accessories Real-time Testing Checkweigher Scale

Grain Automatic Checkweigher Customized Checkweigher Conveyor

Hot Labels:automatic check weigher,intelligent sorting scale,checkweigher,express, weighing scale,conveyors belt,manufacturer,supplier

The multi-lane checkweigher fo...

View MoreThe box check weigher with met...

View MoreThe digital soft gel capsules ...

View MoreThis capsule tablet checkweigh...

View MoreShampoo bag multi-lane checkwe...

View MoreBottle rotary weighing checkwe...

View More