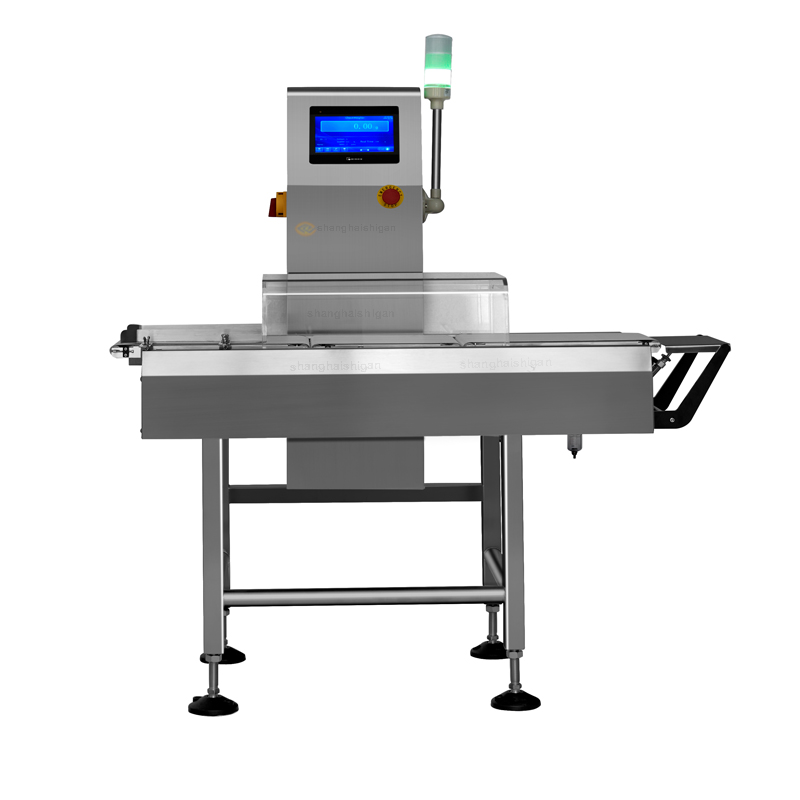

This series of automatic high speed checkweigher scales is suitable for checking weighing of plastic bottle packaging products on medium and high speed production lines. Automatic weight sorting scales are generally installed at the back end of production lines such as production instruments and automatic packaging. The purpose is to dynamically weigh and count product weights, sorting settings to prevent defective products from leaving the factory, and to protect consumers while analyzing measurement data for further manage production.

Product Description

This series of automatic high speed checkweigher scales is suitable for checking weighing of plastic bottle packaging products on medium and high speed production lines. Automatic weight sorting scales are generally installed at the back end of production lines such as production instruments and automatic packaging. The purpose is to dynamically weigh and count product weights, sorting settings to prevent defective products from leaving the factory, and to protect consumers while analyzing measurement data for further manage production.Our product specifications and sizes are rich, various styles, welcome the vast number of willing to buy friends contact us for quotation information.

Specification parameter

Type SG-150H

Weighing Range 3-500g

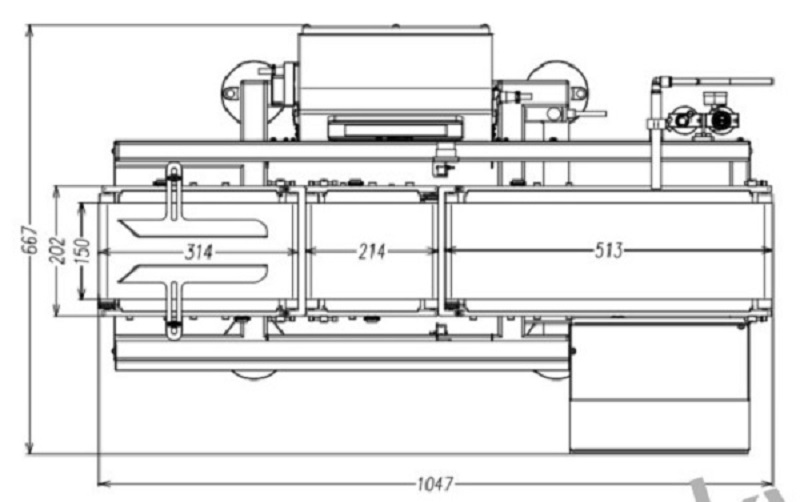

Limited of product L: 100 W:150 H: 3-150mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 90 m/min

Max Speed 160 pcs/min

Belt Width 150mm

Machine Weight 60kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

1.The highest checkweighing capacity and accuracy of the checkweigher vary according to the actual test product, the selection part and the application environment.

2.The size is for reference only and can be customized.

Main Features of high speed online weighing sorting scale

1. Structural improvement: The center of gravity of the whole machine is moved down, and the chassis is more stable.

2. The display instrument can be rotated by 360° horizontally and 180° vertically, making it more convenient to watch the screen.

3. Self-directed sorting organization, the sorting speed is fast in the industry.

4. Better sealing performance, higher waterproof grade, stronger resistance to external interference.

5. Conveyor belt is easy to disassemble and install, convenient to install, repair and maintain.

6. Powerful data statistics storage function, which can pre-store 200 formula data and store tens of thousands of records.

7. The speed of the conveyor is adjustable, which can meet the requirements of the site and effectively ensure the working accuracy.

8. Various expansion devices can be installed according to user requirements.

Application

The plastic bottle automatic checkweigher is widely used in industries that require precise weight detection, such as medicine, fine chemicals, cosmetics, light industry, batteries, health products, food, precision machining, and so on.

About Shanghai Shigan Industrial Co,.Ltd

Shanghai Shigan Industrial Co., Ltd. is located in the beautiful scenery of Shanghai, China. It has been engaged in the production and development of assembly line packaging weighing equipment since 2010, and has obtained CE certification and a number of professional certificates. The company has always been adhering to the "innovative, high-quality, and efficient" business philosophy. Provide you with perfect, high-quality products and services. Now our company's products have been sold all over the world, and have gained the trust and praise of countless customers!

Our main products are: automatic checkweighers, digital metal detectors, vertical packaging machines, premade bag packaging machines, multihead weighers, linear scales, and a series of assembly line packaging testing equipment.

After-sale Service

After-sales service commitment:

1. Service tenet: fast, decisive, accurate, thoughtful and thorough

2. Service goal: service quality wins customer satisfaction

3. Service efficiency: If the equipment fails during the warranty period or outside the warranty period, our company will arrange maintenance personnel to provide maintenance services for customers within 24 hours after receiving the notice.

4. Service principle: The product warranty period is one year. During the warranty period, our company will repair the parts damaged due to quality reasons for free. If the parts are damaged outside the warranty period, the provided accessories will only charge cost. If due to human factors If the equipment is damaged, the parts repaired or provided by our company will be calculated at the cost price.

Related Products

20kg Accessories Real-time Weighing Checkweigher

Customized Checkweigher Conveyor For Textile

Check Weigher Rejector For 30kg Price

Dynamic Weight Checker Supplier

Checkweigher Manufacturers Supply

100kg Assembly Line Roller Scale Price

Multi-stage Checkweigher for Meat

Hot Labels:plastic bottle check weigher,automatic checkweigher,high speed weight checker,online check weight machine,weighing sorting scale,manufacturer,supplier,price

The softgel capsule metal dete...

View MoreThis large capacity checkweigh...

View MoreThe rotary checkweigher for be...

View MoreThis pharmaceutical packaging ...

View MoreThis dual-lane checkweigher fo...

View MoreThis high-speed bottle weighin...

View More