The sorting and rejecting checkweigher adopts a uniquely designed mechanical structure and operation interface, which is very convenient for users to operate and manage data. When in use, the operator only needs to simply set the upper and lower limits of the inspected items and press the [Start] button, the system will enter a fully automatic working state, qualified products will pass, and unqualified products will be automatically rejected. At the same time, information such as quantity, speed, weight, product information, status graphics, etc. are displayed on the man-machine interface.

Products Description

The sorting and rejecting checkweigher adopts a uniquely designed mechanical structure and operation interface, which is very convenient for users to operate and manage data. When the automatic checkweigher in use, the operator only needs to simply set the upper and lower limits of the inspected items and press the [Start] button, the system will enter a fully automatic working state, qualified products will pass, and unqualified products will be automatically rejected. At the same time, information such as quantity, speed, weight, product information, status graphics, etc. are displayed on the man-machine interface.You are welcome to contact us at any time for further information.

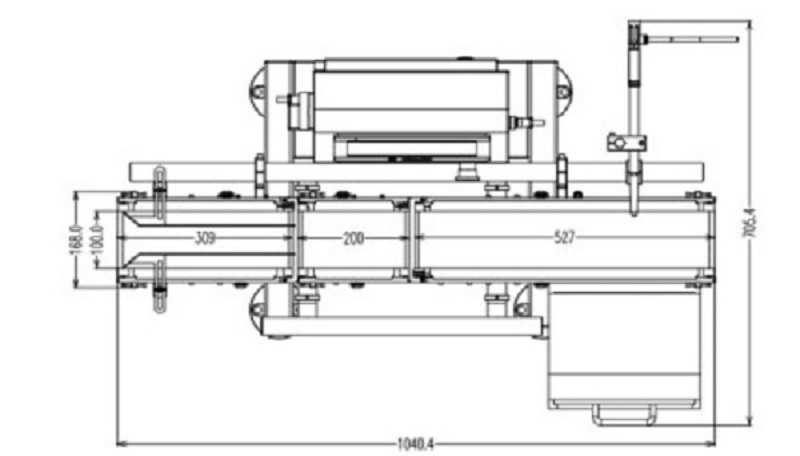

Specification parameter

Type SG-100

Weighing Range 2-300g

Limited of product L: 100 W: 100 H: 2-150mm

Accuracy ±0.5g Depends on product

Division Scale 0.01g

Belt Speed 0- 80 m/min

Max Speed 300 pcs/min

Belt Width 100mm

Machine Weight 60kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

1.The highest checkweighing capacity and accuracy of the checkweigher vary according to the actual test product, the selection part and the application environment.

2.The size is for reference only and can be customized.

Main Advantages

1: Color man-machine touch screen

2: Chinese and English man-machine friendly operation interface

3: 500 recipe settings can be stored

4: Query at any time including target value, upper limit, lower limit, qualified number, unqualified number and other information

5: All stainless steel materials are suitable for various food and pharmaceutical industries

6: Waterproof type with protection grade IP67 can be selected, suitable for aquatic products and slaughter industry

7: With automatic learning and self-checking functions

8: A variety of different rejection methods can be selected according to different products

9: configure USB port, export data

10: Dynamic checkweigher can be connected to external equipment such as printers, code readers, metal detectors, etc.

Application

Weighing sorting and rejecting checkweigher equipment is widely used in food, medicine, chemical, hardware, daily necessities and other industries to check the weight of items on the production line.

About Us

Founded in 2010, Shanghai Shigan Co., Ltd. is a high-tech enterprise specializing in R&D, production and sales of testing equipment. The company has been focusing on the development and sales of automatic checkweighers, digital metal detection equipment, vertical packaging machines and other assembly line equipment for more than ten years. It has become a well-known professional equipment manufacturer and service provider in the industry. The main products are automatic checkweighers. , Digital metal detection equipment, vertical packaging machines, premade bag packaging machines, linear scales, weighing labeling machines, etc. Companies attach great importance to independent research and development ability training and technical team construction, and have formed a technical team with independent research and development capabilities. , To ensure that the company can continue to introduce new products that meet customer needs.

After-sales service commitment:

1. Service tenet: fast, decisive, accurate, thoughtful and thorough

2. Service goal: to win customer satisfaction with high-quality service quality

3. Service efficiency: If the equipment fails during the warranty period or outside the warranty period, after the supplier receives the notice, the maintenance personnel can reach the site and start the repair within 24 hours.

4. Service principle: The product warranty period is twelve months. During the warranty period, the supplier will repair and replace the parts damaged due to quality reasons free of charge. If the parts are damaged outside the warranty period, only the cost of the parts provided will be charged. For equipment damage caused by human factors on the demand side, the repair or accessories provided by the supplier will be calculated at cost.

5. After the warranty period, our company's sales staff will return visits to investigate user usage no less than three times a year.

Related Products

Overweight / Underweight Detection Checkweigher

Plastic Particle Real-time Dynamic Packing Machine

Automatic Weighing Checkweigher Unqualified Test Scale

Dynamic Weight Labeling Machine

Fertilizer Granule Packaging Machine

Small Package Automatic Checkweigher

Hot Labels:120g,150g,300g,weighing,sorting,rejecting,checkweigher,weighing scale equipment,weight checker,manufacturer,supplier

The multi-lane checkweigher fo...

View MoreThe box check weigher with met...

View MoreThe digital soft gel capsules ...

View MoreThis capsule tablet checkweigh...

View MoreShampoo bag multi-lane checkwe...

View MoreBottle rotary weighing checkwe...

View More