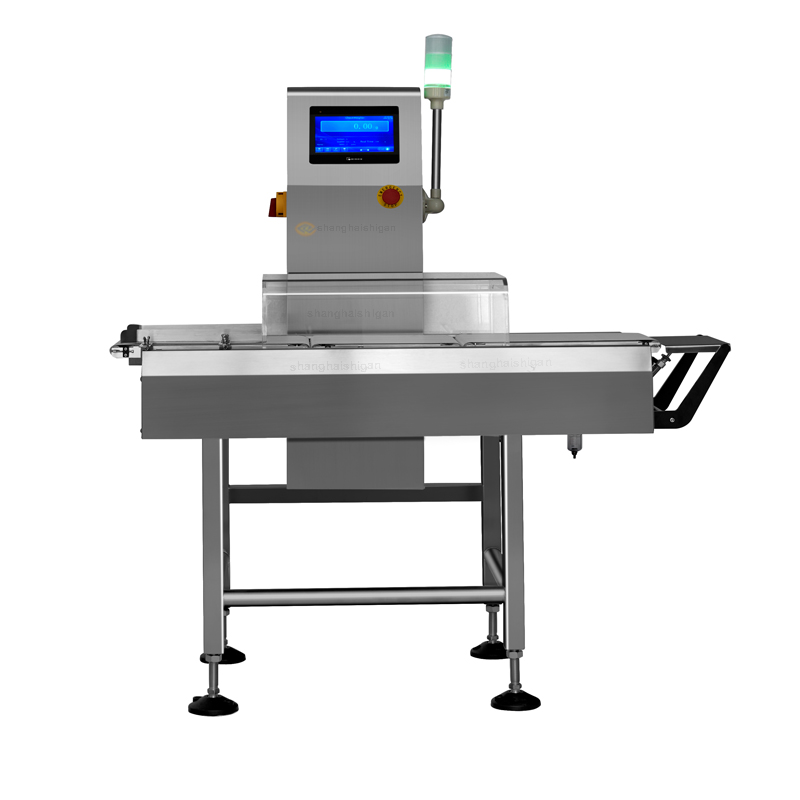

The plaster weight scale checking machine adopts advanced weighing technology and a simple design method, which is economical and affordable, ensuring stable and reliable checkweighing accuracy and speed. The dynamic checkwigher interface is beautiful and simple. At the same time, it can also count and display production data. The weighing range is 5-15000 grams, and the USB data interface is optional. The weight data of each product can be exported to the computer, which can be used for product quality analysis and production management.

Product Information

The plaster weight scale checking machine adopts advanced weighing technology and a simple design method, which is economical and affordable, ensuring stable and reliable checkweighing accuracy and speed. The dynamic checkwigher interface is beautiful and simple. At the same time, it can also count and display production data. The weighing range is 5-15000 grams, and the USB data interface is optional. The weight data of each product can be exported to the computer, which can be used for product quality analysis and production management.For further information about our machine,please do not hesitate to contact us.

Specification Parameter

Type SG-220

Weighing Range 5-1500g

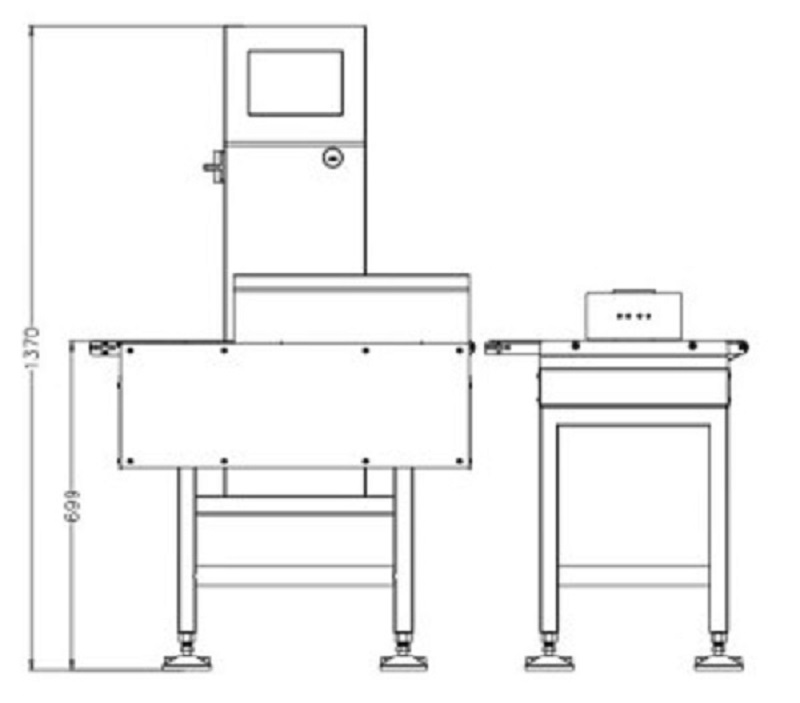

Limited of product L: 300 W:220 H: 3-200mm

Accuracy ±0.2g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 100 pcs/min

Belt Width 220mm

Machine Weight 60kg+44kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

Main Features

1.High precision: Imported high-speed weighing module and weight sensor are used to ensure detection accuracy

2.Simple structure: The whole machine is made of stainless steel. The structure is simple and easy to maintain and maintain. It conforms to GMP and HACCP specifications.

3.Convenient operation: Schneider touch screen is used for simple operation, intuitive display and support for multiple languages (default Chinese and English)

4.Convenient external connection: It can be connected to other equipment in the production line, such as printer labeling machine and inkjet printer, etc.

5.Wide range of uses: for the weight detection of bagged filling products, a variety of rejection methods can be selected (dial lever type, air blowing type, push can type, etc.

6.Automatic feedback function: It can feed back the packaging accuracy to the front-end equipment signal in time to adjust the feeding status of the connected equipment

Application

The dynamic checkweigher is widely used in food, agriculture, fishery, chemical, light industry, medicine, building materials, machinery, electronics, energy, textile, packaging, health care products, cosmetics and other industries.

About Us

Shanghai Shigan Industrial Co., Ltd. is located in the beautiful scenery of Shanghai, China. It has been engaged in the production and development of assembly line packaging weighing equipment since 2010, and has obtained CE certification and a number of professional certificates. The company has always been adhering to the "innovative, high-quality, and efficient" business philosophy. Provide you with perfect, high-quality products and services. Now our company's products have been sold all over the world, and have gained the trust and praise of countless customers!

Our main products are: automatic checkweighers, digital metal detectors, vertical packaging machines, prefabricated bag packaging machines, multi-head weighers, linear scales, and a series of assembly line packaging testing equipment.

Sale Service

1. Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2. After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

After-sales service commitment

1. Service tenet: fast, decisive, accurate, thoughtful and thorough

2. Service goal: service quality wins customer satisfaction

3. Service efficiency: If the equipment fails during the warranty period or outside the warranty period, our company will arrange maintenance personnel to provide maintenance services for customers within 24 hours after receiving the notice.

4. Service principle: The product warranty period is one year. During the warranty period, our company will repair the parts damaged due to quality reasons for free. If the parts are damaged outside the warranty period, the provided accessories will only charge cost. If due to human factors If the equipment is damaged, the parts repaired or provided by our company will be calculated at the cost price.

Related Products

Thin Products Assembly Line Checkweigher Grain Dynamic Belt Scale Weight Checker

Inline Weighing Labeling Machine For Jars Screw Factory Belt Sorting Line Checkweigher

Juice High-speed Packing Machine Vertical Heavy Product Durable Check Weigher Price

Multi-function Multi-head Combination Weigher Large Capacity Filling Machine Supply

Hot Labels:plaster,weight scale,checking machine,pharmaceutical,industry,dynamic,checkwigher,price

The digital soft gel capsules ...

View MoreThe multi-lane checkweigher fo...

View MoreShampoo bag multi-lane checkwe...

View MoreBottle rotary weighing checkwe...

View MoreThe quantitative capsule table...

View MoreStable heavy carton check weig...

View More