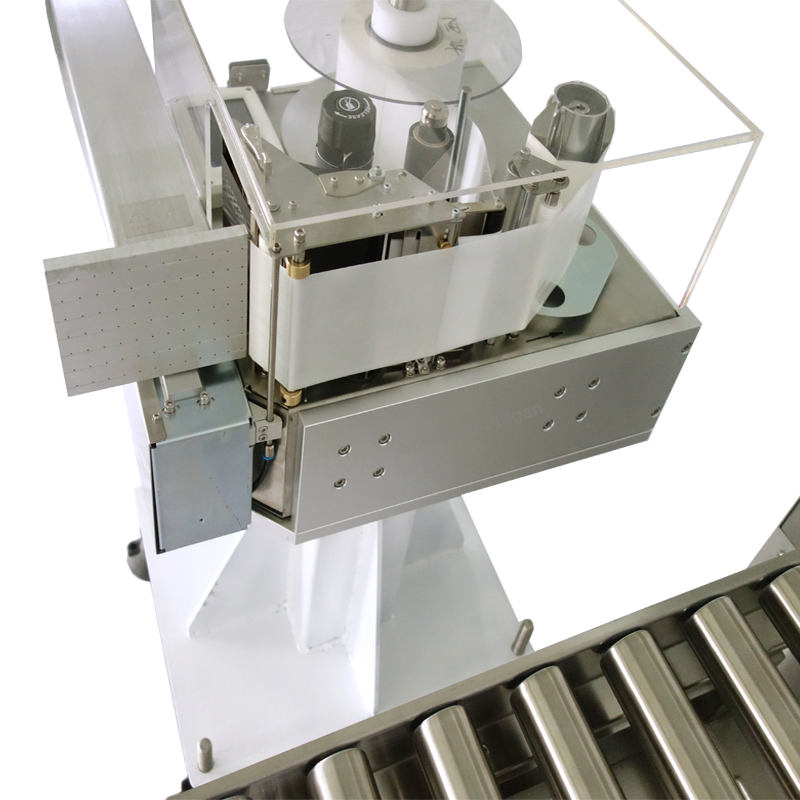

Food high efficient weighing labeling machine is manufactured by Shanghai Shigan. This weighing and printing labeling machine of our company is a production and packaging equipment that improves labor efficiency. The weighing unit and the labeling unit are integrated, which can print real-time weight labels, production date and other variable information. Set the unit price of the product and automatically calculate the total price of a single product. Inline checkweigher labeling machine can also be connected to the system to generate a two-dimensional traceability code to trace the product.

Product Information

Food high efficient weighing labeling machine is manufactured by Shanghai Shigan. This weighing and printing labeling machine of our company is a production and packaging equipment that improves labor efficiency. The weighing unit and the labeling unit are integrated, which can print real-time weight labels, production date and other variable information. Set the unit price of the product and automatically calculate the total price of a single product. Inline checkweigher labeling machine can also be connected to the system to generate a two-dimensional traceability code to trace the product.For further information about our machine or services,please do not hesitate to contact us.

Weighing labeling machine parameters

Weighing range: 5g—1500g

Detection accuracy: ±0.5g (the larger the weight, the faster the speed, the worse the accuracy, depending on the product size, speed, and weight)

Minimum scale: 0.1g

Belt width: 220mm

Belt height from the ground: 800mm±50mm

Conveying speed: 20-60m/min (variable frequency control)

Detection speed: 60~120 pieces/min

Conveying direction: facing the screen from left to right

Power supply: 220V 50-60HZ

External air source: 0.6—1Mpa

Air pressure interface: ¢8mm

Work rate: about 200W

Dimensions: about 1543mm(L)*721mm(W)*1470±50mm(H)

Host weight: about 100Kg

Features of Inline Weighing Labeling Machine

1. Program storage function: The user can preset the setting parameters (such as the number of tags, delay, alarm processing method, etc.) for various products in the control computer, and call them out when changing production needs, without having to re-use them. set up.

2. A variety of labeling methods: pneumatic, blowing, sweeping and other methods for users to choose, which can meet the labeling requirements of different occasions/different items.

3. Counter function: A variety of counter functions are convenient for users to understand and follow up the production status, material status, label usage, etc. Different counting methods can greatly improve the flexibility of users for different production and statistical needs.

3. Alarm function: When a fault occurs, the system will pop up corresponding alarm information or shut down, so that the user can clearly understand the fault situation. (Optional alarm modes include: "close/open" signal and "stop/non-stop" command, etc.).

4. The function of real-time printing and labeling and anti-leakage labeling. The function of automatic labeling (reprinting) can be selected to meet the special needs of the production line.

5. Flexible editing software: Compatible with most Chinese/English label editing software, printing content editing has strong flexibility.

6. Extended function: It can be connected with other equipment (such as: barcode reader, electronic pop, testing equipment or other industrial equipment, etc.) to form an integrated system to meet the user's complex production management and logistics monitoring application requirements.

7. Connection function: Connect to the main system via Ethernet to achieve the purpose of real-time management and system integration, eliminating the need for on-site configuration and control of the computer.

9. Easy to use: The touch screen is equipped with a humanized Chinese-English bilingual user interface, which is simple and easy to use.

10. Easy to install: stand up stand, easy to adjust; the distance between objects is large, which reduces the need for fine-tuning during installation. Using imported electrical components from world-renowned brands to ensure the long-lasting stability and reliability of the whole machine

Application

1.Automatic checkweigher and labeling machine is mainly used for the weighing of the product itself on the automated assembly line, and to print labels containing real-time weight information and carry out real-time labeling.

2.Inline weighing labeling can replace manual weighing, printing and labeling. In this way, the production efficiency and the consistency and reliability of weighing, printing and labeling are improved.

3.High efficient weighing labeling is widely used in food, medicine, daily chemical, industrial manufacturing, printing, logistics and other industries.

About Us

Shanghai Shigan Co., Ltd. is a weighing machinery automation equipment manufacturer integrating R&D, design, production and sales. Located in the developed area of the machinery industry-Shanghai, China, it upholds "Excellent Service, Good Quality". The company has complete equipment and independently produces various mechanical transmissions and hardware accessories. The courage to research innovative technology and continuous improvement has won unanimous praise from the majority of enterprises. Always committed to the research and development and manufacturing of automatic checkweighers, digital metal detectors, weighing labeling machine,vertical packaging machines, feed bag packaging machines, multihead weighers, linear scales, etc., to bring products with balanced performance and price to the world A corner.

After Sale Service

Based on the spirit of pursuing high-quality products and customer satisfaction, Shanghai Shigan Industrial solemnly promises you with the principles of preferential prices, considerate service, and reliable product quality.

1.Product quality commitment:

(1). The manufacturing and testing of products have quality records and testing data.

(2). For product performance testing, we sincerely invite users to personally check the whole process and performance of the product, and then pack and ship the product after it is confirmed to be qualified.

2. Product price commitment:

(1). Under the same competitive conditions, our company will sincerely provide you with preferential prices on the basis of not reducing product technical performance or changing product components.

3. Delivery time commitment:

(1). Product delivery time: Try to meet user requirements. If there are special requirements, it needs to be completed in advance, and strive to meet user needs.

Related Products

Industrial Explosion-proof Checkweigher Manufacturer Juice High-speed Automatic Packing Machine Vertical

Wholesale Heavy Product Durable Check Weigher Intelligent Multihead Weigher For Medicine

Online Weighing Checkweigher Supplier Large Capacity Filling Machine Supply

Digital Online Reinspection Scale Assembly Line Checkweigher Clamping Conveyor

Hot Labels:high efficient,inline,weighing labeling machine,jars,food,automatic,checkweigher labeling machine,manufacturer,supplier

The carton packaged food check...

View MoreThe industrial check weigher f...

View MoreMini high accuracy checkweighe...

View MoreThe coffee beans bag checkweig...

View MoreThe core part of the high-prec...

View MoreFood package multi-level sorti...

View More