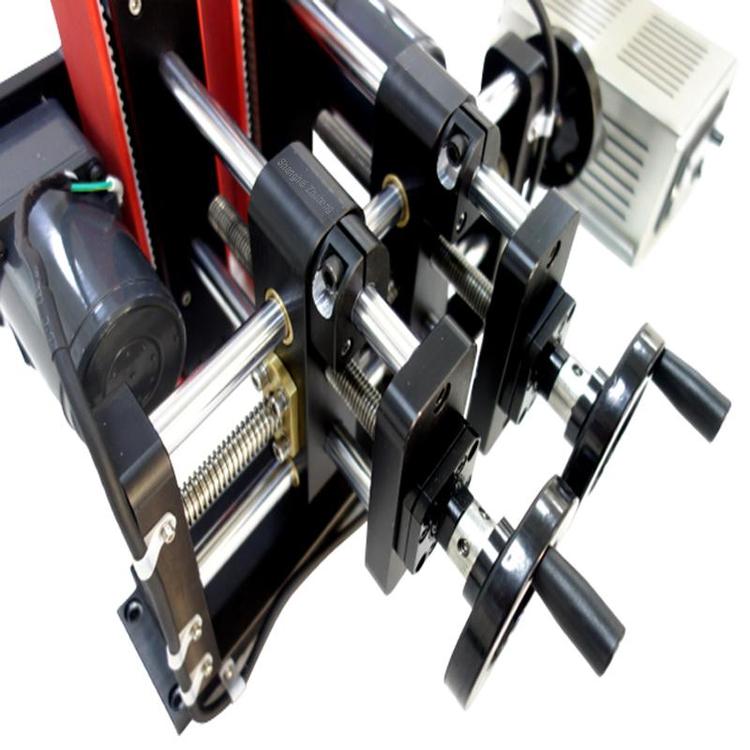

Shanghai Shigan factory products assembly line checkweigher clamping conveyor is mainly used for the transmission of bottled wine, beverages, cosmetics, food, products and other products on the assembly line. Our high speed bottle clamping conveyor is made of stainless steel, which is stable and can be connected to the production line. Equipment, such as: checkweigher, packaging scale, inkjet printer, labeling machine, etc., welcome users who need to call for detailed consultation.

Products Description

Shanghai Shigan factory products assembly line checkweigher clamping conveyor is mainly used for the transmission of bottled wine, beverages, cosmetics, food, products and other products on the assembly line. Our high speed bottle clamping conveyor is made of stainless steel, which is stable and can be connected to the production line. Equipment, such as: checkweigher, packaging scale, inkjet printer, labeling machine, etc., welcome users who need to call for detailed consultation.For further information about our machine,please contact us.

Advantages of clamping conveyor

1. The high speed checkweigher clamping conveyor can save the transportation space and the utilization rate of the plant.

2. The bottle clamping conveyor check weigher realizes the continuity of conveying, and the conveying is not affected by the high speed of conveying.

3. The cargo conveyed by the clamping conveyor should not be too large and heavy.

4. The automatic clamping conveyor is suitable for continuous cleaning of bottles and cans.

5. The assembly line clamping conveyor has simple structure, operation and easy maintenance.

Clamping conveyor parameters:

1. Standard speed: 0-20m/min (adjustable)

2. Passing capacity between belts: 10mm~165mm

3. Length\width\height=650mm\360mm\900mm

4. Voltage requirement: 220V

Features of clamping conveyor

Using drive motor, frequency converter and conveyor belt, it runs more smoothly, with better performance and longer service life;

The whole machine is aluminum alloy modular structure, installation and disassembly;

1. Body material: stainless steel or aluminum alloy profile

2. Power device: frequency conversion motor 60 W×2

3. Controller: frequency converter

4. Transmission device: chain\synchronous belt\chip base belt

5. Conveyor belt: kelp

Application

Clamping conveyors are widely used in the pharmaceutical, food, toy, hardware, chemical and other industries.

After Sale Service

1. Service tenet: fast, decisive, accurate, thoughtful and thorough

2. Service goal: service quality wins customer satisfaction

3. Service efficiency: If the equipment fails during the warranty period or outside the warranty period, our company will arrange maintenance personnel to provide maintenance services for customers within 24 hours after receiving the notice.

4. Service principle: The product warranty period is one year. During the warranty period, our company will repair the parts damaged due to quality reasons for free. If the parts are damaged outside the warranty period, the provided accessories will only charge cost. If due to human factors If the equipment is damaged, the parts repaired or provided by our company will be calculated at the cost price.

Related Products

Dry Powder Premade Pouch Filling Packing Machine High Quality Automatic Checkweigher Price

Food Sorting Equipment Recheck Scale Digital Metal Detection Machine Manufacturers

Dextrose Filling Packing Machine Wholesale Cookie 10 Head Quantitative Multihead Weigher

Intelligent Food Pouch Check Weight Machine Toy Blocks Automatic Metal Detector

Hot Labels:assembly line,checkweigher clamping conveyor,high-speed,bottle,check weigher auxiliary equipment,clamping conveyor,factory

The carton packaged food check...

View MoreThe industrial check weigher f...

View MoreMini high accuracy checkweighe...

View MoreThe coffee beans bag checkweig...

View MoreThe core part of the high-prec...

View MoreFood package multi-level sorti...

View More