The dynamic checkweigher system judges its weight, detects whether its weight meets the specified weight requirements, and prompts whether it is qualified, overweight, or underweight, or executes the corresponding non-conforming product removal action (according to the user's needs), and rejects it. The product launches the production line. The automatic weight che system has the functions of weight detection, classification statistics, alarm, sorting, and weight grouping.

Product Information

The dynamic checkweigher system judges its weight, detects whether its weight meets the specified weight requirements, and prompts whether it is qualified, overweight, or underweight, or executes the corresponding non-conforming product removal action (according to the user's needs), and rejects it. The product launches the production line. The automatic weight checker system has the functions of weight detection, classification statistics, alarm, sorting, and weight grouping.Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

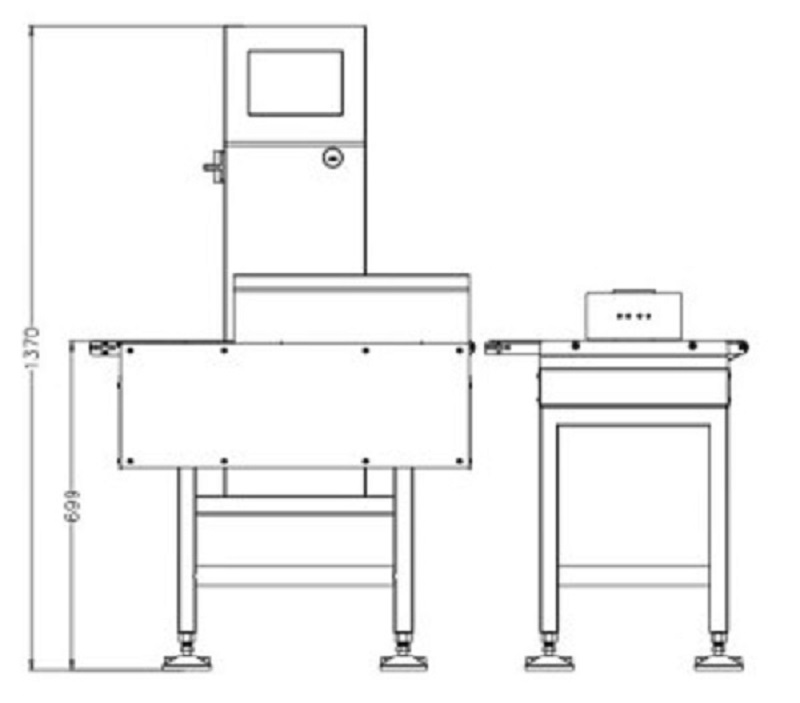

Specification Parameter

Type SG-220

Weighing Range 5-1500g

Limited of product L: 300 W:220 H: 3-200mm

Accuracy ±0.2g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 100 pcs/min

Belt Width 220mm

Machine Weight 60kg+44kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

Main Advantages

Strong versatility: The standardized structure of the automatic weight sorting checkweigher and the standardized human-machine interface can complete the weighing of various materials;

Easy to replace: a variety of formulas can be stored, easy to change product specifications;

Simple operation: using Weilun color man-machine interface, fully intelligent and humanized design;

Easy maintenance: the conveyor belt is easy to disassemble, install and maintain, and is easy to clean;

Adjustable speed: the motor is controlled by frequency conversion, and the speed can be adjusted as required;

High-speed and high-precision: high-precision digital sensors are used, with fast sampling speed and high precision;

Zero tracking: can be manually or automatically cleared, and dynamic zero tracking;

Application

Grain weight sorting checkweigher is widely used in online high-speed packaging checkweighing applications in pharmaceutical, food, health care, daily chemical, battery, light industry and other industries.

About Us

Shanghai Shigan Co., Ltd. was founded in 2010 and is located in Shanghai. Shanghai Shigan has an independent large-scale R&D institution, a complete manufacturing system and a huge marketing service network. It is an international assembly line packaging and testing equipment manufacturer integrating R&D, manufacturing, marketing and service. At present, our company's products have passed the CE EU certification and exported to Europe, the United States, Singapore, Thailand and other countries and regions. The products are widely used in food, medicine, daily chemical, chemical, agricultural and veterinary drugs and other industries. Over the years, the company has continued to carry out technological transformations, and the product quality has been significantly improved, which has been highly recognized by customers at home and abroad. The main products are: automatic checkweigher, digital metal detector, vertical packaging machine, premade bag packaging machine, weighing labeling machine, multihead scale, linear scale, roller scale, etc.

Sale Service

1. Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2. After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Shanghai Shigan Industrial Co., Ltd. has always pursued lofty ideas and solved all needs for customers. Our company solemnly promises you with the principle of "low price, good service, and high-quality products":

⑴ Service tenet: fast, decisive, accurate, thoughtful and thorough

⑵Service goal: service quality wins customer satisfaction

⑶ Service efficiency: If the equipment fails during or outside the warranty period, the supplier will arrange for maintenance personnel to start repairs within 24 hours after receiving the notice.

⑷Service principle: The product warranty period is twelve months. During the warranty period, the supplier will repair and replace the parts damaged due to quality reasons free of charge. If the parts are damaged outside the warranty period, only the cost will be charged for the accessories provided. For equipment damage caused by human factors on the demand side, the repair or accessories provided by the supplier shall be calculated at the cost price. After the warranty period, our company's technical staff will return visits from time to time to investigate the user's usage.

Related Products

High Efficient Inline Weighing Labeling Machine For Jars Industrial Explosion-proof Checkweigher Manufacturer

Medium Bag Milk Liquid Packaging Machine Wholesale Heavy Product Durable Check Weigher

Multi-head Counterweight Combination Weigher Automatic Large Capacity Filling Machine Supply

FCL Beverage Rejecting Checkweigher Equipment High-speed Checkweigher Clamping Conveyor

Hot Labels:noodle,automatic,weight sorting checkweigher,machine,grain,dynamic,belt scale,weight checker,checkweigher

The carton packaged food check...

View MoreThe industrial check weigher f...

View MoreMini high accuracy checkweighe...

View MoreThe coffee beans bag checkweig...

View MoreThe core part of the high-prec...

View MoreFood package multi-level sorti...

View More