The processing industry checkweigher has flexible customization capabilities, adopts the latest load cell DSP technology, compact design, high speed, high precision, stable operation, simple operation, a variety of rejection systems are optional, and the upstream and downstream equipment is integrated into a complete package inspection String. Bag hi-speed Checkweighers help strengthen quality control, increase production capacity, reduce maintenance, reduce labor, and improve production and management efficiency.

Checkweigher as known as automatic checkweigher(alat penimbang automatik), online check weigher,dynamic weight sorting machine,check weight machine,weighing scale and etc,.

The processing industry checkweigher has flexible customization capabilities, adopts the latest load cell DSP technology, compact design, high speed, high precision, stable operation, simple operation, a variety of rejection systems are optional, and the upstream and downstream equipment is integrated into a complete package inspection String. Bag hi-speed Checkweighers help strengthen quality control, increase production capacity, reduce maintenance, reduce labor, and improve production and management efficiency.Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

Specification Parameter

Type SG-450

Weighing Range 0.05-20/30kg

Limited of product L: 500 W:450 H: 3-400mm

Accuracy ±1g

Division Scale 0.1g

Belt Speed 0- 40 m/min

Max Speed 40 pcs/min

Belt Width 450mm

Machine Weight 100kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

1. The highest checkweighing speed and checkweighing accuracy are different according to the actual product being tested.

2. The standard model is only for selection reference, and the specific parameter requirements are customized according to the actual needs of users.

Main Features

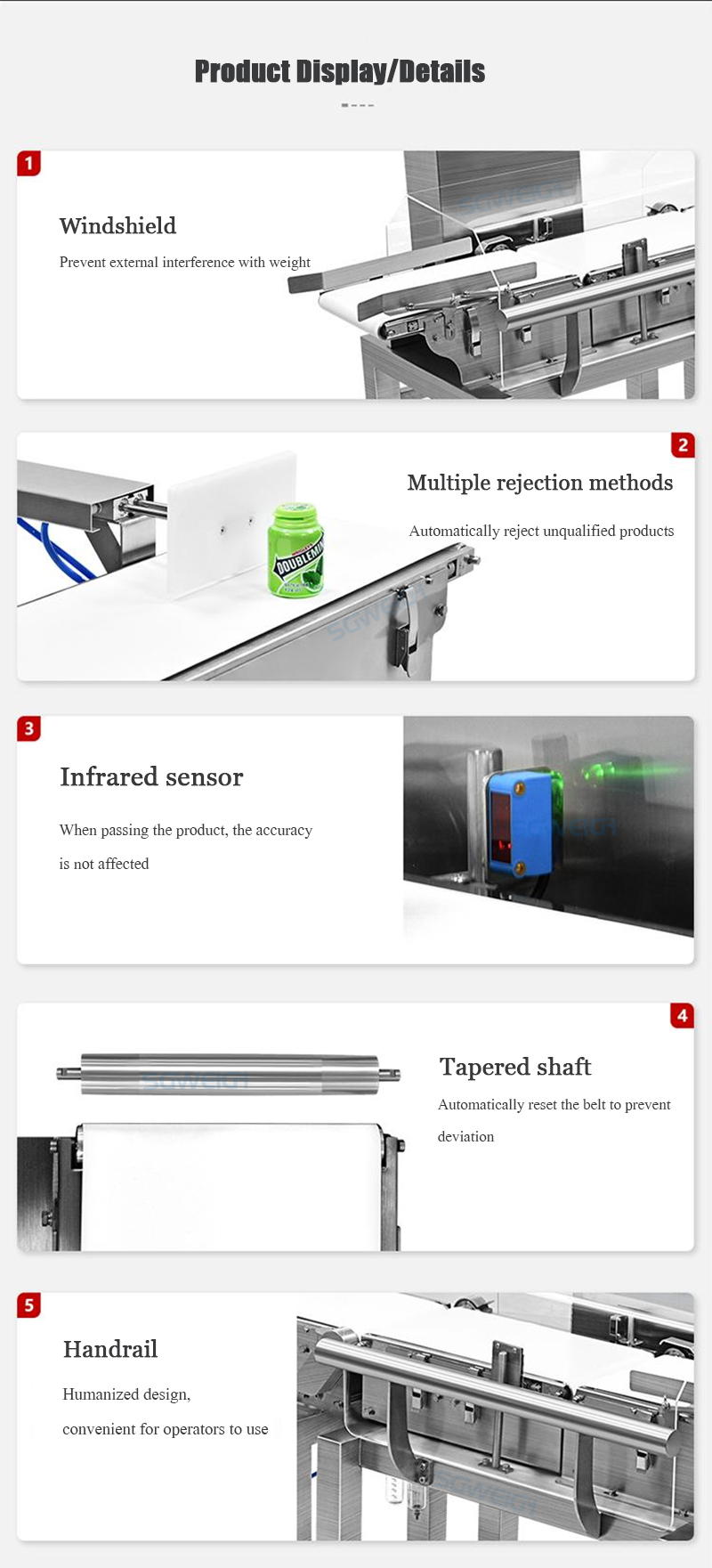

1. Stable high detection accuracy, mature digital phase modulation technology, effectively suppress product effects, so that the system has stable high detection accuracy;

2. Automatic setting function, parameter setting is simple and fast, the system can automatically analyze product characteristics and calculate appropriate detection parameters;

3. User level management function, for different positions, set passwords suitable for different user levels, clarify permissions and responsibilities, and facilitate management;

4. Database function, product database, automatic counting database, detection information recording database, which can quickly realize product switching and historical data query;

5. Humanized design, equipped with intelligent operating system, 7-inch LCD color touch screen, simple screen, simple and intuitive operation, and can easily realize man-machine dialogue;

6. Printer interface, the system has a printer interface, which can print detection information through the printer in real time, and the data can be viewed intuitively and clearly;

7. Support built-in large-capacity SD card to save more data (including test record data, product configuration data, etc.) to meet the requirements of large data volume (optional);

8. Support the function of exporting data via U disk.

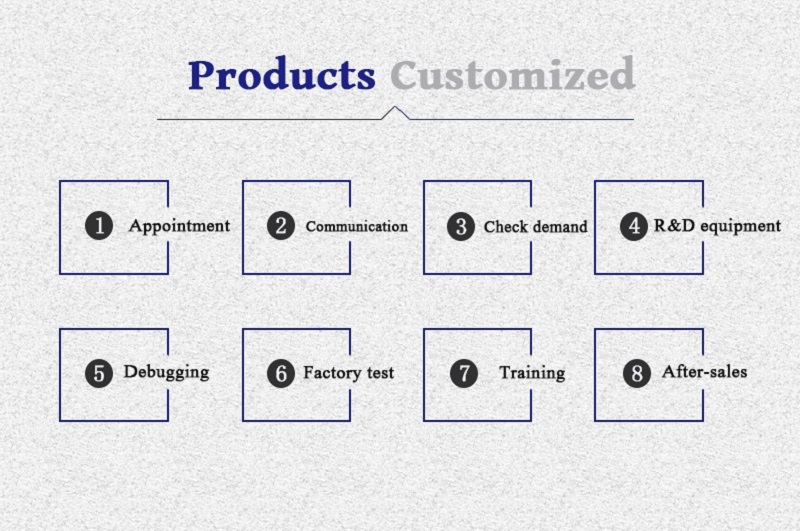

This configuration can also be customized according to customer requirements.

The customized items are as follows:

1. The countertop is tailor-made.

2. Highly tailored.

3. The material can be customized.

4. The meter and the drum can be connected wirelessly,

5. The meter can have its own USB storage function.

6. The meter can send weight data via Bluetooth.

7. The meter can choose automatic quantitative control output function.

8. External printer function.

9. Built-in upper and lower limit alarm lamp function.

10. External scanner function.

11. Other functions

Application

The automatic checkweigher(timbangan otomatis) is mainly used for online detection and selection in the pharmaceutical, food, toy, hardware, chemical and other industries.

1. Check the weight of the product, and eliminate the overweight and underweight products;

2. Check whether the product is missing parts, such as whether there is a lack of instructions in the medicine box, whether the tablets are missing in the box, etc.;

3. Detect whether the product has foreign matter, such as the product contains iron wire, lead, copper, stainless steel and other metals and metal impurities;

4. Products can be classified by weight, such as seafood, aquatic products, poultry, fruits and vegetables, etc. by weight.

Company Profile

Shanghai Shigan Industrial Co., Ltd. was established in 2010. It is a vigorous and rapidly developing company. The company's main products include automatic checkweighers, digital metal detectors, vertical packaging machines, prefabricated bag packaging machines, weighing and labeling machines, multi-head scales, linear scales, dispensing machines, roller scales, etc. dozens of models. Suitable industries include food, hardware, chemicals, medicine, toys, daily necessities and many other industries. The company has professional R&D personnel, after-sales engineers, and pre-sales service personnel to ensure that each set of solutions can make you comfortable and create greater benefits for you. The products we produce and sell are exported to Europe, Africa, South America, the Middle East and other Asian countries and regions, and have won unanimous praise from customers.

After Sale Service

Based on the spirit of pursuing high-quality products and customer satisfaction, Shanghai Shigan Industrial Co,.Ltd solemnly promises you with the principles of preferential prices, considerate service, and reliable product quality.

1.Product quality commitment:

(1). The manufacturing and testing of products have quality records and testing data.

(2). For product performance testing, we sincerely invite users to personally inspect the whole process and performance of the product, and then pack and ship the product after it is confirmed to be qualified.

2. Product price commitment:

(1). Under the same competitive conditions, our company will sincerely provide you with preferential prices on the basis of not reducing product technical performance or changing product components.

3. Delivery time commitment:

(1). Product delivery time: Try to meet user requirements. If there are special requirements, it needs to be completed in advance, and strive to meet user needs.

Related Products

Automatic Detection Weight Sorting Machine

Small Range Chewing Gum Checkweigher

Waterproof Automatic Conveyor Metal Detector

Digital Automatic Checkweigher Customization

Roller Conveyor Belt Weighing Checkweigher

Material Weight Multi-Stage Sorting Checkweigher

Digital Metal Detection Machine

Capsule Tablet Checkweigher Machine

Food Checkweigher Manufacturer

Hot Labels:dynamic,digital,processing,industry,power,roller,checkweigher, bag,hi-speed,checkweigher,reject,scale

This industrial spray bottle c...

View MoreThis multi-lane checkweigher f...

View MoreThe multi-lane checkweigher fo...

View MoreThe box check weigher with met...

View MoreThe digital soft gel capsules ...

View MoreThis capsule tablet checkweigh...

View More