The large-capacity checkweigher is embedded in the product production line, and each product that passes through the dynamic automatic checkweigher is checked one by one according to the preset weight standard. The entire inspection process is unattended and fully automated. The weight selection scale can be set freely for online weighing and detection, and it supports data export and network communication.

The large-capacity checkweigher is embedded in the product production line, and each product that passes through the dynamic automatic checkweigher is checked one by one according to the preset weight standard. The entire inspection process is unattended and fully automated. The weight selection scale can be set freely for online weighing and detection, and it supports data export and network communication.

Specification Parameter

Type SG-550

Weighing Range 0.5-50Kg

Limited of product L: 800 W:550 H: 3-400mm

Accuracy ±20g Depends on product

Division Scale 1g

Belt Speed 0- 40 m/min

Max Speed 30 pcs/min

Belt Width 550mm

Machine Weight 150kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

Main Advantages

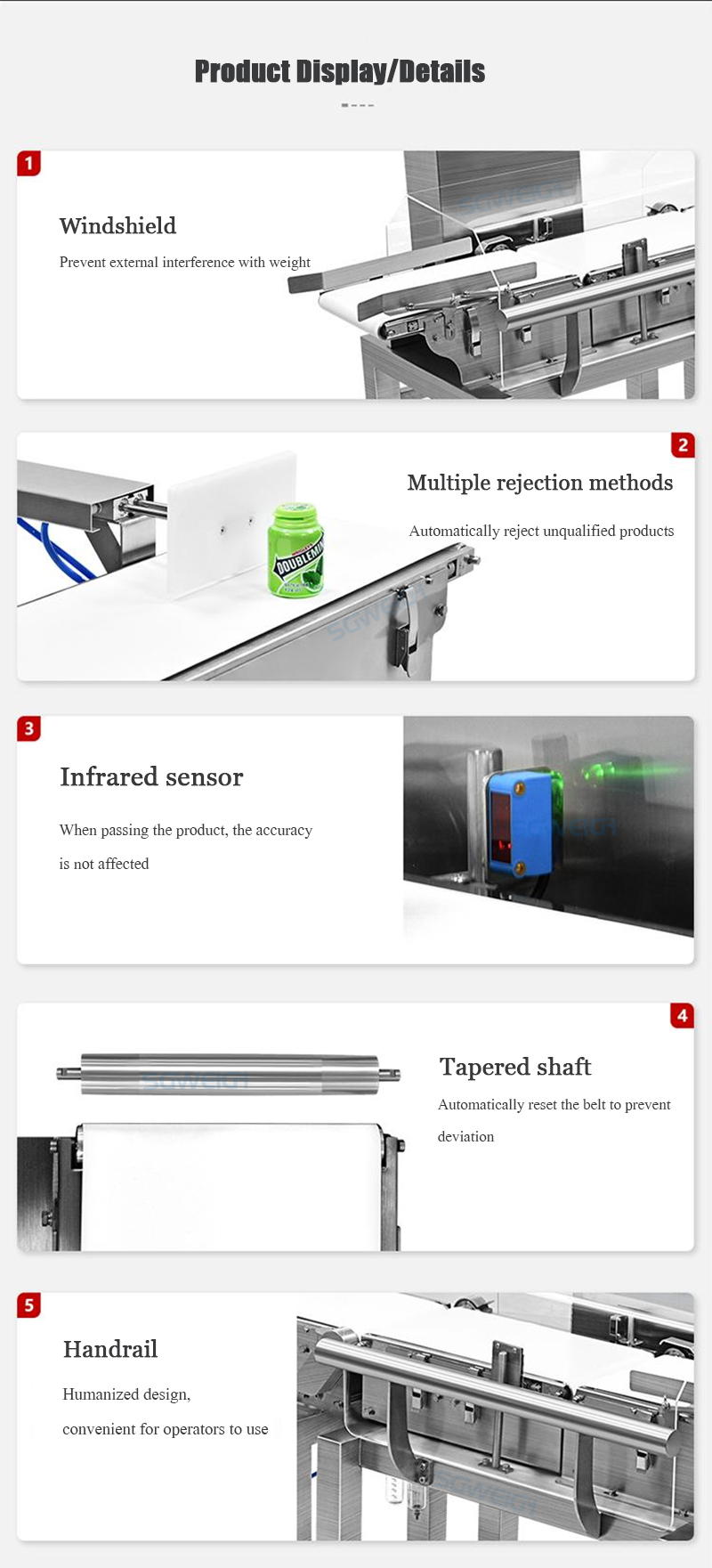

1. Long-term use, accuracy guarantee, no daily calibration

2. Automatic dynamic zero tracking technology

3. With built-in hinge design, there is no safety dead angle, the belt is quickly installed and disassembled, and it is easy to clean and maintain

4. Professional man-machine interface design

5. Concise user parameter setting, automatic parameter adjustment, only need to input product parameters and weighing requirements to complete the parameter setting

6. Accurate and efficient removal mechanism

7. Humanized function, product database can store 1000 kinds of products

8. The password protection function ensures that unauthorized personnel cannot change the data

9. With data statistics function, support data export, USB and Ethernet interface

This digital automatic checkweigher is connected with other auxiliary devices to increase inspection efficiency and effectively manage production.

①The food and fruit production line is connected with the metal detector to determine whether the metal has flowed in or not and sort it.

②Connect the scanner and inkjet printer to print the production date, production batch number, and product weight on the product.

③Install the printer, and output the weight value, daily production volume and production status according to the product.

Application

The automatic checkweigher is mainly used for online detection and selection in the pharmaceutical, food, toy, hardware, chemical and other industries.

1. Detect the weight of the product, and eliminate the overweight and underweight products;

2. Check whether the product is missing parts, such as whether there is a lack of instructions in the medicine box, whether the tablets are missing in the box, etc.;

3. Detect whether the product has foreign matter, such as the product contains iron wire, lead, copper, stainless steel and other metals and metal impurities;

4. Products can be classified by weight, such as seafood, aquatic products, poultry, fruits and vegetables, etc. by weight.

Company Profile

Shanghai Shigan is a manufacturer of assembly line packaging testing equipment with many years of experience. It is committed to providing products with assembly line packaging machine checkweigher solutions, while greatly improving efficiency and increasing industrial productivity in an energy-saving manner. Main products: automatic checkweighers, digital metal detectors, vertical packaging machines, premade bag packaging machines, weighing and labeling machines, multi-head scales, linear scales, checkweigher and metal detector combo, etc. Products are sold to more than 30 countries and regions including the United States, Brazil, Russia, Thailand, India, Britain, Colombia, Myanmar, and Ukraine.

After Sale Service

1. Service tenet: fast, decisive, accurate, thoughtful and thorough

2. Service goal: service quality wins customer satisfaction

3. Service efficiency: If the equipment fails during the warranty period or outside the warranty period, our company will arrange maintenance personnel to provide maintenance services for the customer within 24 hours after receiving the notice.

4. Service principle: The product warranty period is one year. During the warranty period, our company will repair the parts damaged due to quality reasons free of charge. If the parts are damaged outside the warranty period, the provided accessories will only charge the cost. If due to human factors If the equipment is damaged, the parts repaired or provided by our company are calculated at the cost price.

Related Products

Roller Conveyor Belt Weighing Checkweigher

8-level High-Precision Weight Checker

Weighing Equipment For Cheese Food Industry

Double Probe Food Needle Detector

Digital Metal Detection Machine

Capsule Tablet Checkweigher Machine

Food Checkweigher Manufacturer

Hot Labels:large-capacity,industrial,raw,material,dynamic,checkweigher, digital,automatic,checkweigher,customization

This industrial spray bottle c...

View MoreThis multi-lane checkweigher f...

View MoreThe multi-lane checkweigher fo...

View MoreThe box check weigher with met...

View MoreThe digital soft gel capsules ...

View MoreThis capsule tablet checkweigh...

View More