Automatic checkweigher (Penimbangan otomatis)as known a […]

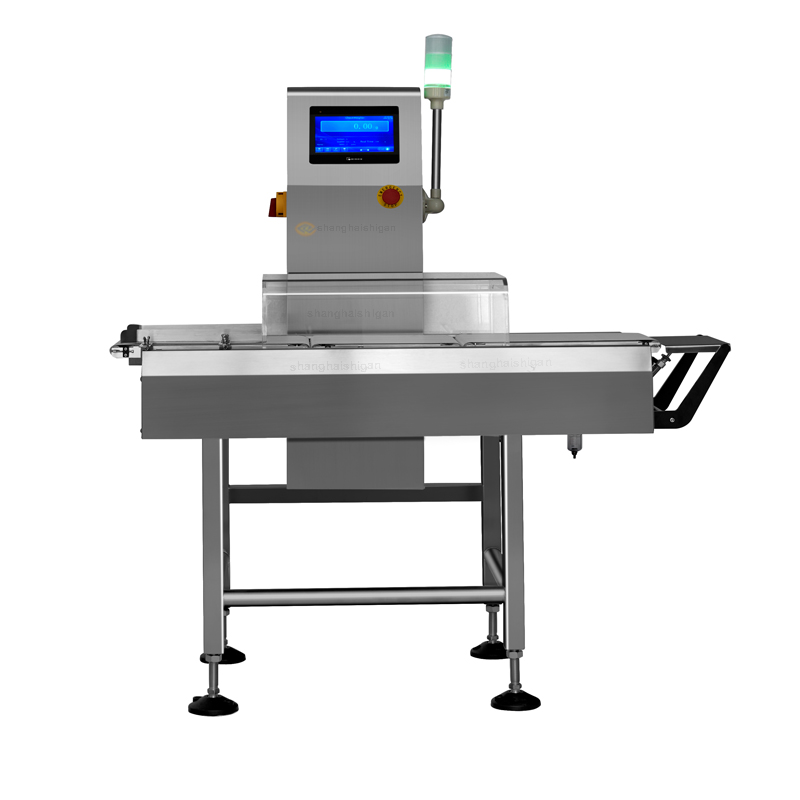

Automatic checkweigher (Penimbangan otomatis)as known as online check weigher,dynamic check weight machine,weight checker,weighing scale,sorting machine and etc,.

Automatic checkweigher is a weighing equipment used in the assembly line of modern production workshops. On the production line, the dynamic check weigher is based on the dynamic weighing technology, which realizes the functions of automatically transporting the products "in motion" to the weighing platform for weighing and automatically classifying and rejecting them. Dynamically inspect the net weight of commodities in the campaign, and remove the foods whose net weight does not pass. The online checkweigher(Pemeriksa dalam talian) on the production line can sort and classify the net weight of the commodities according to customer regulations, and carry out statistical analysis of the classification of the commodities. So what are the advantages of the weighing machine in the production of flowing water, and in which fields can the weighing machine be used in the production of flowing water, let's take a look today!

What are the advantages of the weighing machine in the production line?

The final inspection of the weight of the product by the automatic checkweigehr on the production line of the production line is to re-inspect the weight of the product in the final stage of product production, and reject the unqualified products to ensure that the weight of the products out of the factory meets the requirements. The online weight sorting checkweigher can be integrated with various packaging production lines and conveying systems, and can detect overweight and underweight unqualified products in the production line in real time, and whether there are missing parts in the packaging. Check weighers are widely used in the automatic weight detection of production lines in the pharmaceutical, food, chemical, beverage, plastic, rubber and other industries. They are also an indispensable link in the production process of the food and pharmaceutical industries.

Automatic Checkweigher Performance

1. Long-term use, accuracy guarantee, no daily calibration

2. Automatic dynamic zero tracking technology

3. With built-in hinge design, there is no safety dead angle, the belt is quickly installed and disassembled, and it is easy to clean and maintain

4. Professional man-machine interface design

5. Concise user parameter setting, automatic parameter adjustment, only need to input product parameters and weighing requirements to complete the parameter setting

6. Accurate and efficient removal mechanism

7. Humanized function, product database can store 1000 kinds of products

8. The password protection function ensures that unauthorized personnel cannot change the data

9. With data statistics function, support data export, USB and Ethernet interface

The above is the sharing brought to you today. Hope it will be helpful to everyone.Shanghai Shigan Industrial Co,.Ltd has more than 10 years of experience in the manufacture of checkweighers, has overcome countless problems, obtained many patents, and has successfully provided hundreds of customers with efficient assembly line checkweigher solutions. The products are sold at home and abroad. If you have any questions , Please feel free to contact us!

Related Products

Vertical Hardware Counting Packing Machine

Bag Hi-speed Checkweigher Reject Scale

Spring Hardware Inline Dynamic Checkweigher

Small Range Chewing Gum Checkweigher System

High Precision Automatic Conveyor Metal Detector

Large-Capacity Industrial Raw Material Checkweigher

This metal detector for aluminum foil packaging medicine is a new generation of microcomputer intell...

View MoreSmall Cookie Packaging 10 Head Quantitative Multihead Weigher Shigan's modified series of digital fo...

View MoreThis high precision automatic metal detector is suitable for food, cosmetics, pharmaceutical, chemic...

View MoreMetal detectors for small metal are widely used in various processing and packaging industries such ...

View MoreGrain automatic weighing checkweigher is a device that can automatically detect whether the weight i...

View MoreThis FCL beverage weighing rejecting checkweigher equipment detects the weight of the products on th...

View More