The steak printing weighing labeling machine can weigh and position packaging items at high speed, with various forms and methods of labeling, including blowing, rotating, and stamping labeling heads. The high precision checkweigher and labeling machine can replace manual weighing, printing, and labeling, thereby improving production efficiency, consistency, and reliability of weighing, printing, and labeling.

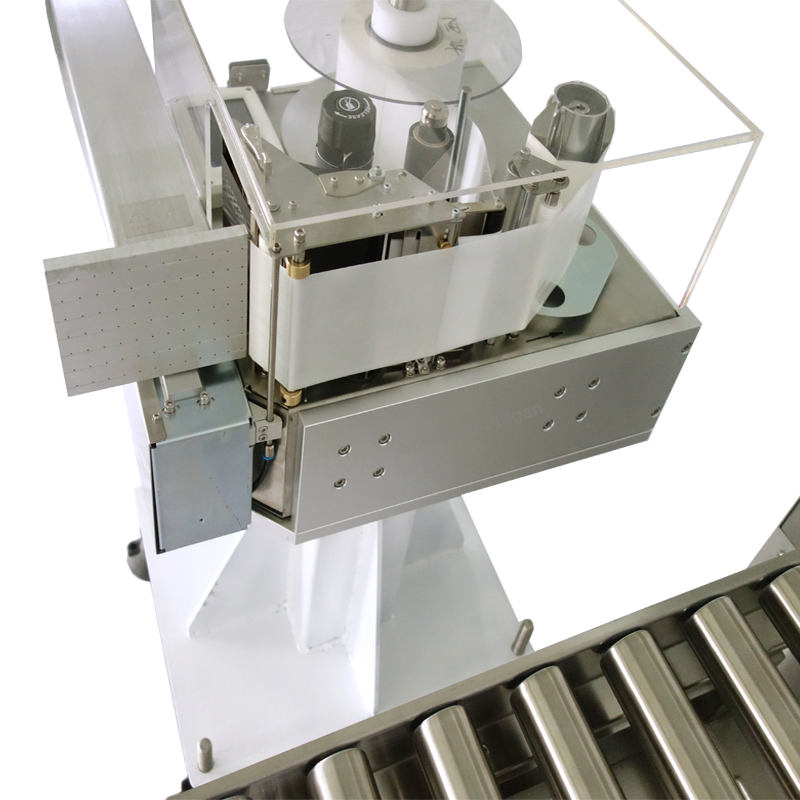

Steak Multifunctional Printing Weighing Labeling Machine High Precision Checkweigher and Labeling Machine

The steak printing weighing labeling machine can weigh and position packaging items at high speed, with various forms and methods of labeling, including blowing, rotating, and stamping labeling heads. The high precision checkweigher and labeling machine can replace manual weighing, printing, and labeling, thereby improving production efficiency, consistency, and reliability of weighing, printing, and labeling. Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

Steak printing weighing labeling machine pictures

Material: SUS304

Direction: From right to left/from left to right

Label core: standard 75mm

Label roll: maximum 300mm

Bottle size: diameter: 20-150mm, height: 30-350mm

Label size: 10-480mm long and 20-200mm wide

Speed: 60-120 pieces/minute (based on box or tray and label size)

Accuracy: ± 1mm

Power: 220/380V 50/60Hz 1000W

Weight: 500kg

Machine size: 2400 * 1000 * 1700mm (length * width * height)

(1) Applicable labels: self-adhesive labels, self-adhesive films, electronic regulatory codes, barcodes, etc.

(2) Applicable products: Products that require labeling on the circumferential and conical surfaces; Single or double labels can be applied.

(3) Application industries: Widely used in food, medicine, packaging, printing, logistics equipment, IT digital, household appliances, stationery and toys, precision manufacturing, agricultural product processing and other industries

1. Powerful, one machine can basically label all products that require labeling, which can greatly improve labeling production efficiency and reduce equipment investment costs;

2. The transmission components are wrapped, and the circuit and air circuit are arranged separately to avoid abnormalities, making it easier to use;

3. The labeling is flat, wrinkle free, and bubble free, with high precision and good stability;

4. The main materials of the equipment are stainless steel and aluminum alloy, with a solid overall structure and beautiful appearance;

5. Adopting a standard PLC+standard sensor electronic control system for stable equipment performance control;

6. Complete equipment supporting materials (including equipment structure, principle, operation, maintenance, repair, upgrade and other explanatory materials), providing sufficient guarantee for the normal operation of the equipment;

7. Steak printing weighing labeling machine has fault alarm function and production counting function; Easy operation and maintenance;

There is no identical production line, and there is no steak printing weighing labeling machine applicable to all production lines. In order to meet the needs of different production lines, our professional engineers will rigorously evaluate factors such as production line characteristics, specifications, and environment, and tailor the most suitable automatic printing weighing labeling machine scheme for you.

We are Shanghai Shigan Industrial Co., Ltd., an instrument expert headquartered in Shanghai, China. Since 2010, we have been specializing in the production of assembly line checkweighers, metal detectors, weighing labeling machines machinery. Over its 15 year history, our products have sold well in the European, American, and Southeast Asian markets, with over 90 countries in total over the years, especially favored by European and American countries. Our equipment covers a wide range of industries including rubber and plastic, food, packaging, electronics, and more. In addition to standard machines, our R&D team can also customize for you. Just tell us your needs and we will satisfy you.

1. Packaging materials: International standard export packaging boxes are usually used, which have good wear resistance, shock resistance, and waterproof performance. The material of the box can be hard wooden boxes, plastic boxes, or export specific cardboard boxes.

2. Protective measures: In order to ensure that the weigher is not damaged during transportation, it is necessary to add sufficient filling materials, such as foam, shockproof cotton, etc., into the packaging box.

1. Equipment installation and debugging: The company provides detailed operation manuals and free operation training to ensure that customers can proficiently use the equipment.

2. Technical support: The company provides 24/7 technical support to solve problems encountered by customers during use.

3. Accessories supply: The company provides original accessories to ensure the quality and stability of the accessories.

4. Quality assurance: The company is responsible for the products sold, ensuring that the quality and performance of the equipment meet industry standards.

5. Warranty policy: One year warranty, lifetime repair, to solve customers' worries.

Related Products

Cosmetic Facial Mask Pouch Multi-lane Checkweigher

High Speed Box Checkweigher for Food Industry

Pharmaceutical Box Pouch Multi-stage Sorting Checkweigher

Seafood Checkweigher Metal Detector Combo with Dual Removal

Biscuit Food Metal Detector with Automatic Alarm

Cosmetic Bag Packaging Assembly Line Checkweigher

Hot Labels: steak,multifunctional,printing,weighing labeling machine,high precision,checkweigher and labeling machine,supplier,manufacturer

The multi-lane checkweigher fo...

View MoreThe box check weigher with met...

View MoreThe digital soft gel capsules ...

View MoreThis capsule tablet checkweigh...

View MoreShampoo bag multi-lane checkwe...

View MoreBottle rotary weighing checkwe...

View More