These new small strip balance checkweighers are high-speed and precise automatic online weight inspection equipment used to check whether the weight of products on the conveyor belt meets the set target weight tolerance, and can also automatically reject products that are lighter or overweight.The characteristic of automatic balance check weigher is low cost, judgment, strong universality, especially suitable for online testing of packaging products.

SG-1X Automatic Balance Check Weigher Small Strip Checkweigher Factory

These new small strip balance checkweighers are high-speed and precise automatic online weight inspection equipment used to check whether the weight of products on the conveyor belt meets the set target weight tolerance, and can also automatically reject products that are lighter or overweight.The characteristic of automatic balance check weigher is low cost, judgment, strong universality, especially suitable for online testing of packaging products. For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

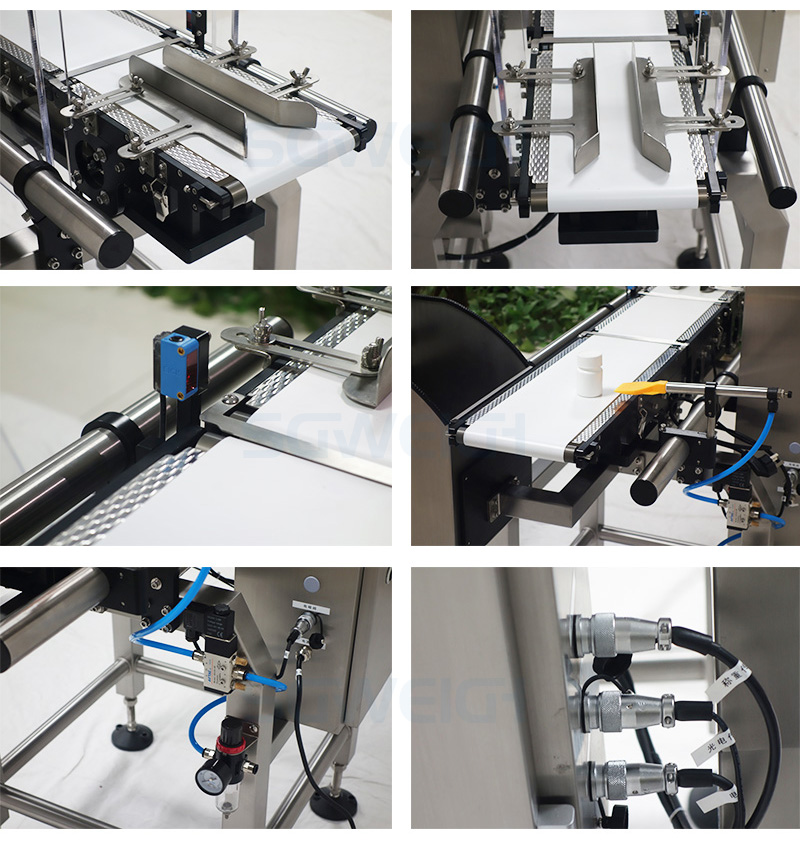

Small strip balance checkweighers photos

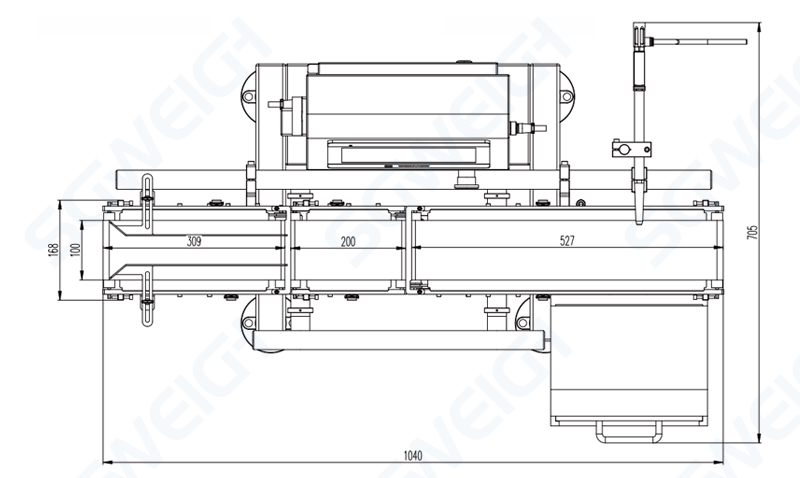

Type SG-1X

Weighing Range 1-50g

Limited of product L: 180 W: 40 H: 2-20mm

Accuracy ±0.01g Depends on product

Division Scale 0.01g

Max Speed 70 pcs/min

Belt Width 100mm

Machine Weight 50kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

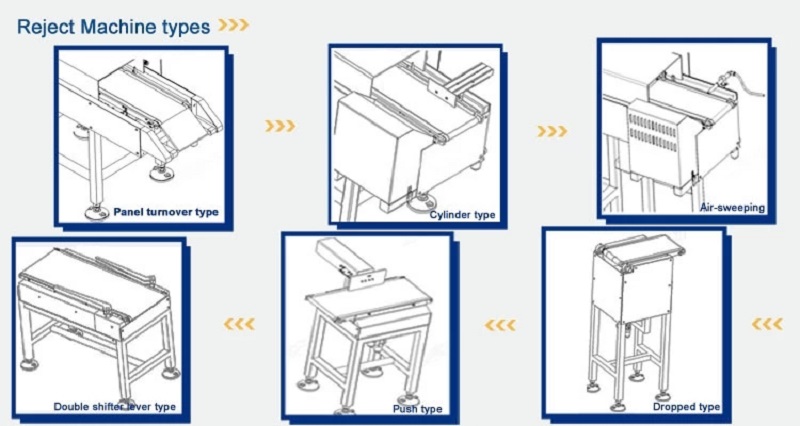

Our company's professional technical personnel will recommend the most suitable type of small strip balance checkweigher removal for you based on your specific needs. You can contact us at any time, and our team will provide professional guidance and support to ensure that your solution can meet your business needs

1. Ultra high adaptability to device environments.

2. Extremely user-friendly operating interface.

3. Parameters can be modified at any time without the need for the weight sorting machine to pause sorting.

4. Up to 200 product presets can store hundreds of thousands of data records, meeting the complex needs of customers.

5. Rich peripheral resources make it easy to connect with other devices.

6. The rapid dynamic weighing algorithm software technology enables the entire system to maintain high detection accuracy even during high-speed operation.

1. Can achieve online weighing of products during dynamic operation

2. Dynamic weighing detection can be carried out according to preset weight requirements

3. Can automatically detect the weight of each product 100%

4. Depending on the speed of the assembly line. Standardized weight testing and troubleshooting based on quality inspection weight parameters

5. Automatically reject products with non-conforming weight or classify them for quality

6. Small strip balance checkweighers are widely used in various industries such as electronic hardware, medicine, food, chemical, beverage, and health products.

Our company introduction

Established in 2010.

2. High tech enterprises in Shanghai.

3. We have over 14 years of experience in the field of automatic checkweigher and have our own factory, which can provide you with the most suitable projects for your needs.

4. 6-8 international machinery exhibitions every year.

5. Supply OEM/ODM manufacturing.

6. Multiple engineers ensure quality/service.

As a manufacturer and trader, we have good quality and price control over our products.

8. The product is exported to over 40 countries, including the United States, Canada, and Mexico; Australia, New Zealand; Saudi Arabia, Italy, Spain; France, Poland, Israel, Russia, South Korea; Thailand, Indonesia, Malaysia, Philippines, etc.

The usual packaging is a wooden box (size: length * width * height). If exported to European countries, wooden boxes will undergo fumigation treatment. If the container is too tight, we will use polyethylene film packaging or packaging according to the customer's special requirements.

1. Customer consultation and technical support: Provide customers with consultation services related to product use, repair, and maintenance, and answer any problems they encounter during operation and use.

2. Technical training: Provide training on product operation, maintenance, and repair to meet customer needs, ensuring that customers can use and maintain products correctly.

3. Accessory supply: Provide original accessories to ensure the quality and performance of the accessories and meet the needs of users.

4. One year warranty and lifelong maintenance

6. After sales service tracking: Track and provide feedback on the after-sales service process, timely understand customer needs and opinions, and continuously improve service quality.

Related Products

Checkweigher and Labeling Machine for Pharmaceutical Factory

Bottle Can High-speed Checkweigher Metal Detector Combo

Automatic Rotating Checkweighers for Bottle Packaging

Ultra-high Speed Boxed Industrial Checkweigher

High Precision Bottle Checkweigher for Cosmetics Industry

Milk Powder Particle Food Metal Detector

Hot Labels:

This multi-lane checkweigher f...

View MoreThe multi-lane checkweigher fo...

View MoreThe box check weigher with met...

View MoreThe digital soft gel capsules ...

View MoreThis capsule tablet checkweigh...

View MoreShampoo bag multi-lane checkwe...

View More