The automatic multi-stage checkweigher weighing machine adopts continuous dynamic automatic weighing method to detect the weight of items, and is equipped with an automatic sorting mechanism, so as to realize high-speed and high-precision weight detection and sorting on the assembly line.The modular design of the seafood multi-stage checkweigher makes the operation and daily maintenance of this series very simple. The product parts are easy to disassemble and clean with water, adopt imported electrical components, have waterproof performance, and simple operation surface. 100 kinds of materials with different weight specifications can be stored, which is convenient for operation and use.

Products Information

The automatic multi-stage checkweigher weighing machine adopts continuous dynamic automatic weighing method to detect the weight of items, and is equipped with an automatic sorting mechanism, so as to realize high-speed and high-precision weight detection and sorting on the assembly line.The modular design of the seafood multi-stage checkweigher makes the operation and daily maintenance of this series very simple. The product parts are easy to disassemble and clean with water, adopt imported electrical components, have waterproof performance, and simple operation surface. 100 kinds of materials with different weight specifications can be stored, which is convenient for operation and use.For further information about our machine, please do not hesitate to contact us.

Specification Parameter

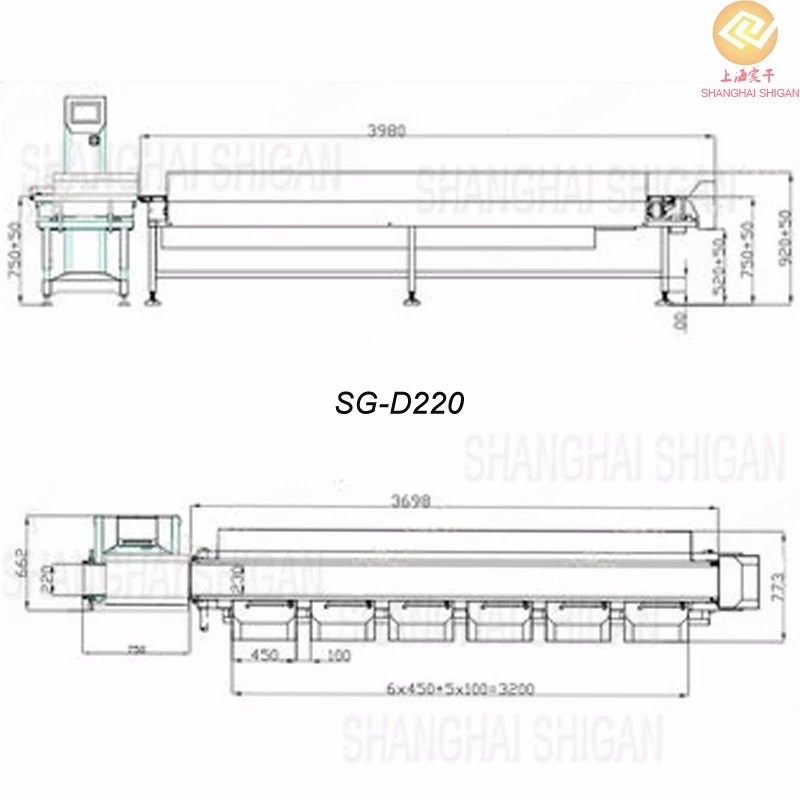

Type SG-D220

Weighing Range 10-1200g

Limited of product L: 200 W:150 H: 3-200mm

Accuracy ±0.2 Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 100 pcs/min

Belt Width 220mm

Machine Weight 60kg+44kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

1.The highest checkweighing capacity and accuracy of the checkweigher vary according to the actual test product, the selection part and the application environment.

2.The size is for reference only and can be customized.

Main performance characteristics of high-precision multi-stage checkweigher

1) The automatic weight sorting checkweigher scale is embedded in the user assembly line to automatically weigh and detect each product to achieve full product inspection;

2) The weight detection range of the dynamic multi-stage checkweigher supports free setting, and the abnormal quality type can be set to automatically reject defective products;

3) The multi-stage weighing machine adopts the HBM weighing module imported from Germany, which can continuously weigh accurately and dynamically;

4) Automatic dynamic weight compensation technology, automatic zero-point tracking and zero-clearing processing technology;

5) The multi-stage checkweigher supports multiple communication protocol interfaces, supports report export, and facilitates production data management

6) The seafood checkweigher has its own fault detection function and automatic power-off protection function;

7) Support 100 kinds of test formula storage, call, modify and use at any time;

8) The speed of the online automatic checkweigher for seafood can be adjusted by frequency conversion, which can flexibly match the speed of the production line;

9) Support full-featured custom service of dynamic multi-stage checkweigher to ensure that it is fully matched to the assembly line weighing equipment

About Us

Founded in 2010, Shanghai Shigan Co., Ltd. is a high-tech enterprise specializing in R&D, production and sales of testing equipment. The company has been focusing on the development and sales of automatic checkweighers, digital metal detection equipment, vertical packaging machines and other assembly line equipment for more than ten years. It has become a well-known professional equipment manufacturer and service provider in the industry. The main products are automatic checkweighers,digital metal detection equipment, vertical packaging machines, premade pouch packing machines, linear scales, weighing labeling machines, weighing filling machine,etc. Companies attach great importance to independent research and development ability training and technical team construction, and have formed a technical team with independent research and development capabilities. , To ensure that the company can continue to introduce new products that meet customer needs.

The company can customize testing equipment of various specifications according to the special requirements of customers, and can carry out engineering design and installation according to the characteristics of the customer's production line, which can be tailor-made for customers. The quality of the company's products is trusted by users and has won praise from customers in domestic and foreign markets. The products have passed the EU CE certification and are sold throughout the country and exported to many foreign countries and regions.

1. Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2. After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

Delivery Detail :

Shipped in 25 days after payment

After Sale Service

1. Service tenet: fast, decisive, accurate, thoughtful and thorough

2. Service goal: service quality wins customer satisfaction

3. Service efficiency: If the equipment fails during the warranty period or outside the warranty period, our company will arrange maintenance personnel to provide maintenance services for customers within 24 hours after receiving the notice.

4. Service principle: The product warranty period is one year. During the warranty period, our company will repair the parts damaged due to quality reasons free of charge. If the parts are damaged outside the warranty period, the provided accessories will only charge the cost. If the equipment is damaged, the parts repaired or provided by our company will be calculated at the cost price.

Related Products

Dropped Type Weight Sorting Machine Specializing In the Production Of Automatic Checkweighers

Food Safety Metal Detector Electronic Component Assembly Line Checkweigher

Packet Filling Machine Price Chemical Powder Prefabricated Bag Packing Machine

Sausage Real-time Weight Checker Pharmaceutical Industry Automatic Sorting System

Hot Labels:seafood,dynamic,multi-stage,automatic sorting,checkweigher,weighing machine,manufacturer,supplier

The multi-lane checkweigher fo...

View MoreShampoo bag multi-lane checkwe...

View MoreBottle rotary weighing checkwe...

View MoreThe quantitative capsule table...

View MoreStable heavy carton check weig...

View MoreThe food multistage weight sor...

View More