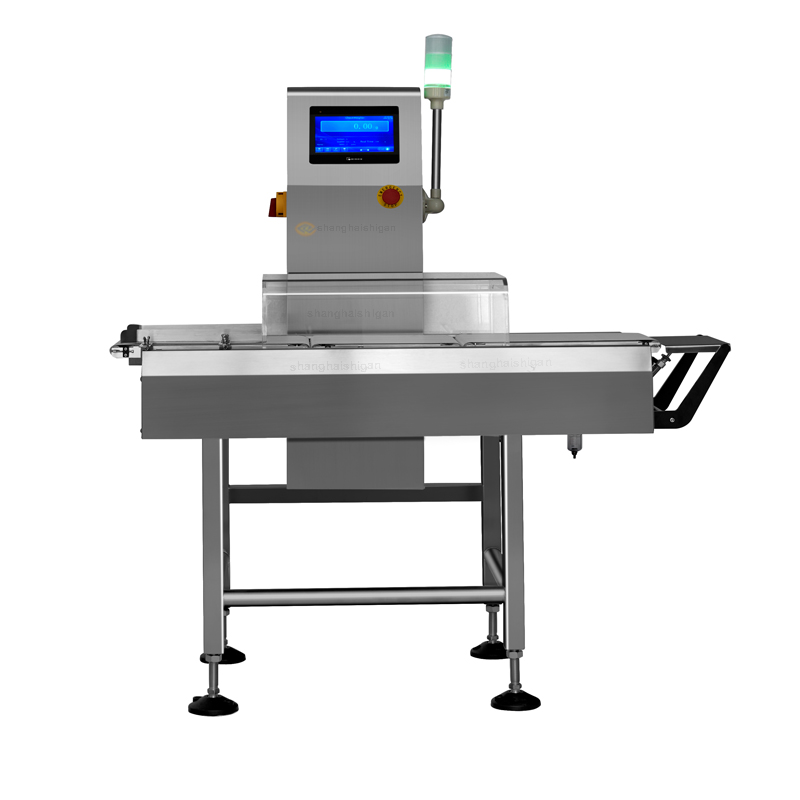

All contact parts of the automatic checkweigher are made of food-grade materials to ensure that the product will not be contaminated and meet the international health requirements. The working principle of the dynamic weight sorting checkweigher is high-speed digital signal processing technology, and the signal output is fast and accurate. The inline automatic checkweigher adopts imported high precision weight sensors with high detection accuracy, strong anti-interference ability and stable operation.

Products Information

All contact parts of the automatic checkweigher are made of food-grade materials to ensure that the product will not be contaminated and meet the international health requirements. The working principle of the dynamic weight sorting checkweigher is high-speed digital signal processing technology, and the signal output is fast and accurate. The inline automatic checkweigher adopts imported high precision weight sensors with high detection accuracy, strong anti-interference ability and stable operation.For further information about our machine and services,please do not hesitate to contact us.

Specification Parameter

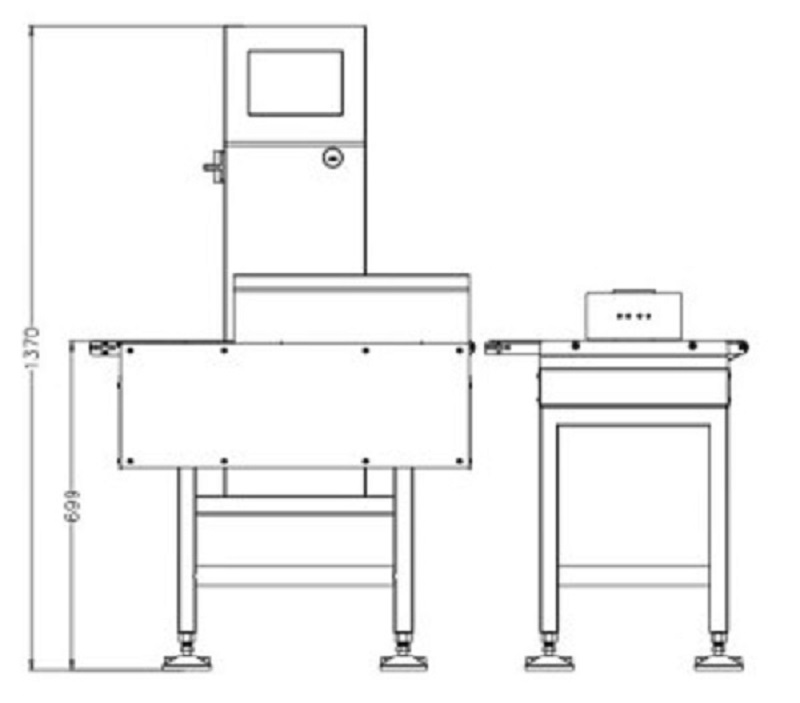

Type SG-220

Weighing Range 5-1500g

Limited of product L: 300 W:220 H: 3-200mm

Accuracy ±0.2g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 100 pcs/min

Belt Width 220mm

Machine Weight 60kg+44kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

1.The highest checkweighing capacity and accuracy of the checkweigher vary according to the actual test product, the selection part and the application environment.

2.The size is for reference only and can be customized.

Customized Philosophy

The product demonstrating may not perfectly meet your requirements,

our philosophy is to customize your real need.

To minimizing idle capacity and function. To supply you performance and cost balanced products. Following are the factors shall be taken into account during customization:

1,Products to be packed

2,Container to be filled, type and specification.

3,Capacity requirement

4, Automation requirement

5, Protection requirement

6, Other specific requirement

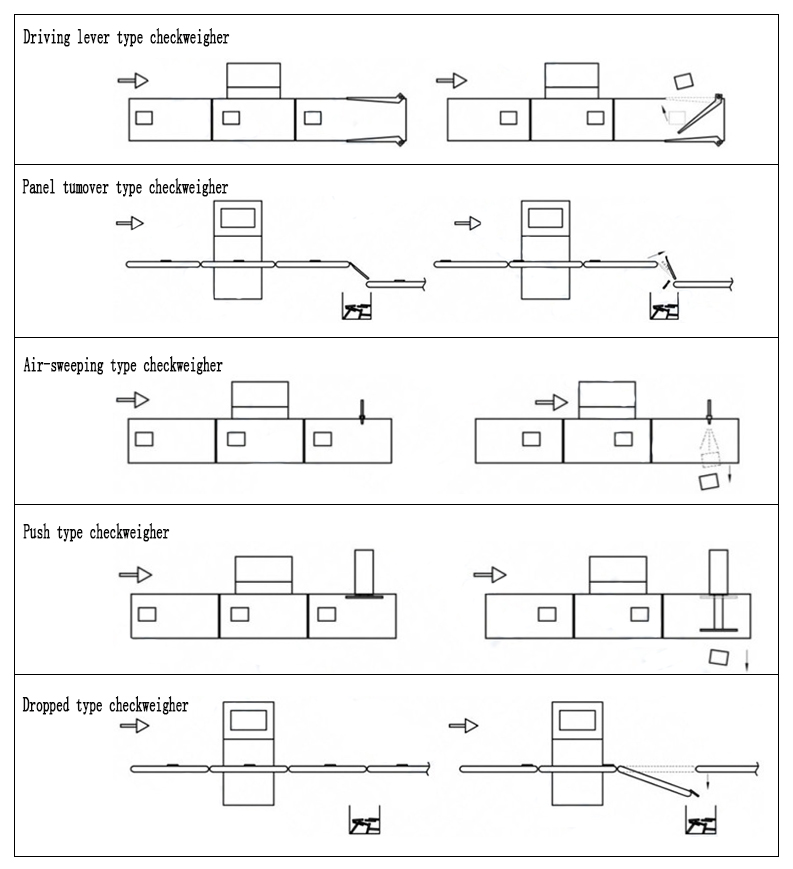

Optional rejection type

1.Air-sweeping Type Checkweigher

Suitable for lighter and regular items, such as instant noodles, paper rolls, small hardware, etc.!

2.Driving Lever Type Checkweigher

Suitable for items that are slightly heavy and not easily damaged, such as: meat, fish, canned food, etc.!

3.Push type Checkweigher

Suitable for heavier items, such as: beverage boxes, milk boxes, metal parts boxes, etc.!

4.Dropped Type Checkweigher

Suitable for items that are thin and the detection speed is not fast, such as: fans, snacks, etc.!

5. Panel Tumover Type Checkweigher

It is suitable for thin and fast detection items, such as masks, seasoning bags, etc.!

Main Advantages

1. Large-size color LCD touch screen interface, simple operation and intuitive display.

2. Support multiple languages: Chinese, English, Spanish, Italian, Japanese, Korean, etc. (customer specified), the default is Chinese and English.

3. It can store 200 kinds of product inspection data, which is convenient for users to call.

4. USB data storage interface, which can transfer report data to PC for analysis and printing.

5. Parameter setting password protection, only management personnel operation.

6. Automatic zero tracking system to ensure reliable detection data.

7. Built-in temperature and noise compensation system to ensure system stability. Online printing function (customization required).

8. Data external communication interface, which can be connected to other equipment in the production line (eg: labeling machine and inkjet printer) (customization required).

9. Simple mechanical structure, easy to disassemble, clean and maintain.

Application

Automatic weight sorting checkweigher is mainly used for the quality inspection and classification of the product itself on the automated assembly line, and can also be used for the detection of multiple and missing parts after product packaging.

Dynamic sorting check weigher can also replace manual weighing to improve production efficiency, consistency and reliability of weighing.

Online automatic checkweigher is widely used in food, medicine, daily chemical, industrial manufacturing, printing, logistics and other industries.

About Us

Founded in 2010, Shanghai Shigan Co., Ltd. is a high-tech enterprise specializing in R&D, production and sales of testing equipment. The company has been focusing on the development and sales of automatic checkweighers, digital metal detection equipment, vertical packaging machines and other assembly line equipment for more than ten years. It has become a well-known professional equipment manufacturer and service provider in the industry. The main products are automatic checkweighers, digital metal detection machine, vertical packaging machines, premade pouch packaging machines, linear scales, weighing and labeling machines,weighing filling machine, etc. Companies attach great importance to independent research and development ability training and technical team construction, and have formed a technical team with independent research and development capabilities.

Related Products

High Speed Powder Weighing Filling Machine Specializing In the Production Of Automatic Checkweighers Manufacturer

Food Safety Metal Detector High Speed Automatic Weight Checker

Automatic Lime Packaging Machine Pharmaceutical Industry Automatic Sorting System

Sausage Real-time Weight Checker Portugal Belt Metal Detector Manufacturers India

Hot Labels:procurement of pipeline,automatic checkweigher, push-rod weight sorting machine,check weigher,dynamic weight checker,manufacturer,supplier

The carton packaged food check...

View MoreThe industrial check weigher f...

View MoreMini high accuracy checkweighe...

View MoreThe coffee beans bag checkweig...

View MoreThe core part of the high-prec...

View MoreFood package multi-level sorti...

View More