Shanghai Shigan provides dynamic check weigher system solutions for bottled products for different size specifications. The online checkweighers for PVC bottles conducts a professional 1 -to -1 customization according to the requirements of the user's assembly line and bottle product detection. The dynamic check weigher system is embedded in the streamline to test online for each bottle of products or packaging, and the unqualified automatic inspection and removal are performed according to the preset standard weight range.

Online Checkweighers For PVC Bottles High-speed Dynamic Check Weigher System Solutions

Shanghai Shigan provides dynamic check weigher system solutions for bottled products for different size specifications. The online checkweighers for PVC bottles conducts a professional 1 -to -1 customization according to the requirements of the user's assembly line and bottle product detection. The dynamic check weigher system is embedded in the streamline to test online for each bottle of products or packaging, and the unqualified automatic inspection and removal are performed according to the preset standard weight range. Bottle high speed checkweigher scale online automatic inspection of each single or packaging product can help enterprises to improve their quality in an all -round way.Our product specifications and sizes are rich, various styles, welcome to contact us for quotation information.

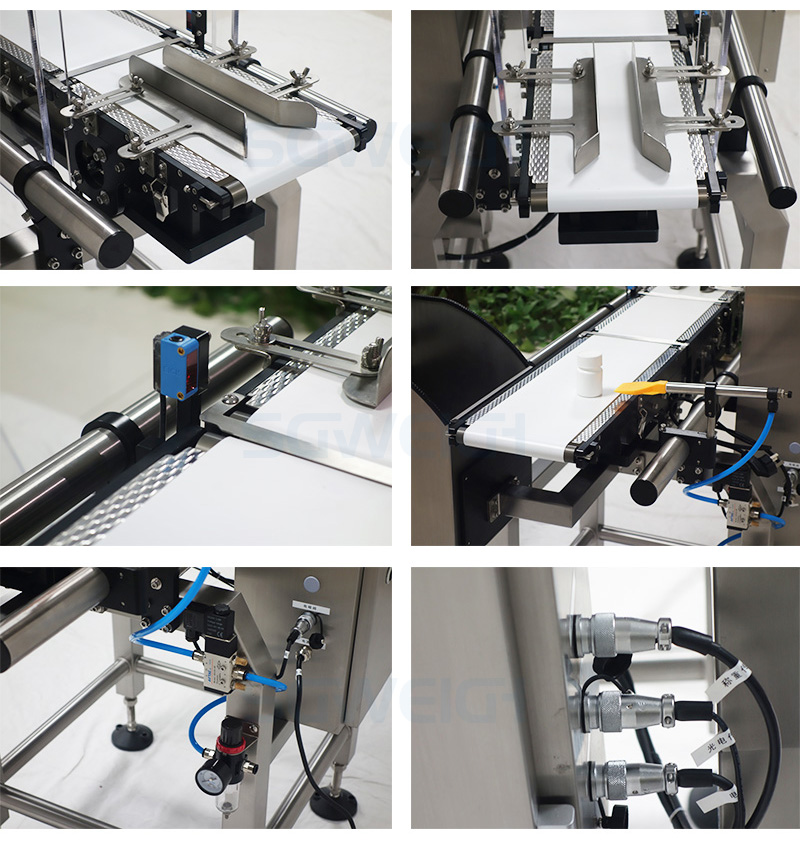

Online checkweighers for PVC bottles photos

1. Dynamic weighing technology to achieve 100% detection:

All products on the production line are tested with high speed and high precision to solve the detection problem of "light" and "small" products. The optimal detection accuracy can reach ± 0.03g, and the sorting speed can reach as fast as 5 pieces/second.

2. Multiple practical function modes to easily handle different products:

It stores 100 groups of product parameters, supports different working modes of weight inspection and multi-stage sorting, and automatically generates weight inspection schemes for products of different specifications. It can easily deal with the detection of bottled, bagged, barreled products, or full container products.

3. Pre emptive status monitoring to reduce capital waste:

The independent and innovative online weighing control software integrates the automatic weighing scale into the existing production line, which not only accurately identifies and eliminates unqualified products, but also identifies the wrong link and gives an alarm in time, reducing the product rejection rate from the root cause and avoiding product waste.

Online Checkweighers For PVC Bottles High-speed Dynamic Check Weigher System Solutions

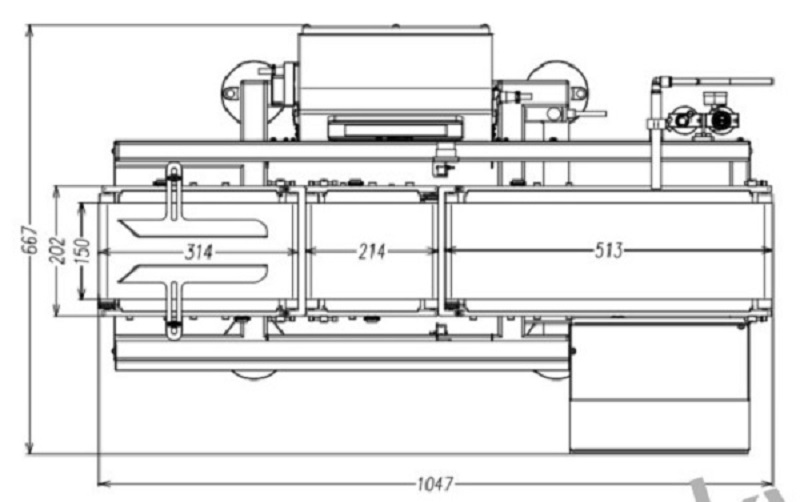

Type SG-150H

Weighing Range 3-500g

Limited of product L: 100 W:150 H: 3-150mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 90 m/min

Max Speed 160 pcs/min

Belt Width 150mm

Machine Weight 60kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

1. The maxi weight inspection speed and precision are different according to the actual tested products.

2. The standard model is only for reference, and the specific parameter requirements are customized according to the actual needs of users.

Dynamic check weigher system is used to test whether the weight of a single product is acceptable or whether the product is packaged. Whether there is any omission in the process, which is widely used in pharmaceutical, food, beverage, electronics, health products, daily chemical, light industry, agricultural and sideline products and many other industries.

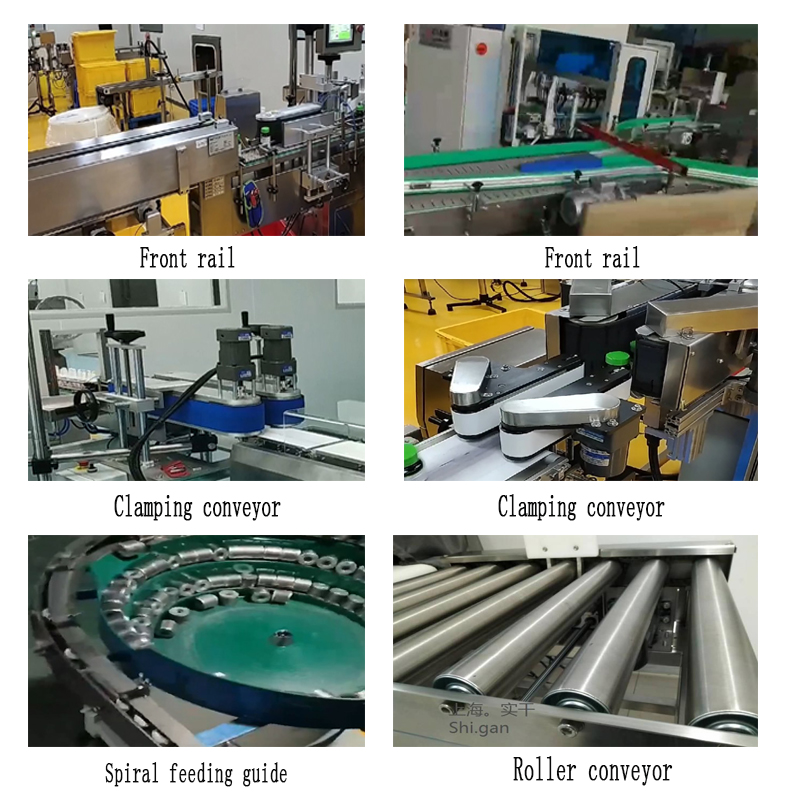

In view of the characteristics of bottled/canned products, in order to prevent damage to bottled products, our company has specially installed guardrails in the buffer weighing area to prevent unnecessary accidents. A variety of guides for you to choose from

Online Checkweighers For PVC Bottles High-speed Dynamic Check Weigher System Solutions

1. Service tenet: fast, decisive, accurate, considerate and thorough

2. Service objective: win customer satisfaction with service quality

3. Service efficiency: In case of equipment failure within or beyond the warranty period, our company will arrange maintenance personnel to provide maintenance services for customers within 24 hours after receiving the notice.

4. Service principle: The product warranty period is one year. During the warranty period, our company will repair the damage of parts caused by quality for free. For the damage of parts beyond the warranty period, only the cost will be charged for the parts provided. If the equipment is damaged due to human factors, our company will repair or provide the parts at the cost price.

Related Products

In-line Checkweigher With USB Port Check Weigher

Digital Metal Detection Machine

Capsule Tablet Checkweigher Machine

Hot Labels:online checkweighers for PVC bottles,high-speed,dynamic,check weigher system,solutions,bottle checkweigher,supply,sale,price

The multi-lane checkweigher fo...

View MoreThe box check weigher with met...

View MoreThe digital soft gel capsules ...

View MoreThis capsule tablet checkweigh...

View MoreShampoo bag multi-lane checkwe...

View MoreBottle rotary weighing checkwe...

View More