The meat multi-level weight sorting checkweigher is specifically designed for continuous weighing, sorting, and batch product inspection on the production line. The weight range is sorted according to the set level in the designated channel, so that the products can be graded and processed at the designated workstation. The automatic multi-level sorting checkweigher adopts a built-in world-class digital weighing unit, which can achieve high-speed, accurate, and stable measurement.

Meat Multi-level Checkweigher Weight Sorting Machine Touch Screen Weight Grading Solutions

The meat multi-level weight sorting checkweigher is specifically designed for continuous weighing, sorting, and batch product inspection on the production line. The weight range is sorted according to the set level in the designated channel, so that the products can be graded and processed at the designated workstation. The automatic multi-level sorting checkweigher adopts a built-in world-class digital weighing unit, which can achieve high-speed, accurate, and stable measurement. For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

Meat multi-level weight sorting checkweigher photos

Type SG-D300

Weighing Range 5-3000g

Limited of product L: 350 W:300 H: 3-200mm

Accuracy ±0.3g-0.5g Depends on product

Division Scale 0.1g

Belt Speed 0- 50 m/min

Max Speed 60 pcs/min

Belt Width 300mm

Machine Weight 60kg+150kg

Power Supply AC 220V 50HZ

Power 1000W

Main Material SU304 stainless steel

1.High performance and maximum efficiency.

2.Large load range with extreme precision.

3.Designed for demanding production environments.

4.Flexible and efficient product handling.

5.Low maintenance costs.

6.Improve production line efficiency. Equipment efficiency across the entire line is improving.

7.The accuracy of the weighing machine ensures that customer interests are not affected.

8.Reduce potential sampling errors and long-term labor costs.

9.Improve product quality to meet customers' strict needs.

10.Cost savings increase product profits.

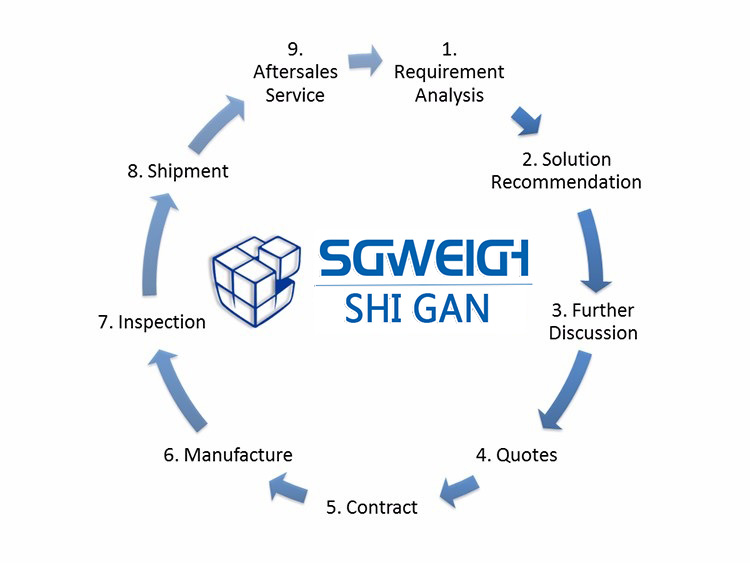

Automatic multi-level weight sorting checkweigher manufacturers offer a wide range of customization options to customize the design, functionality, and specifications of weighing scale systems to meet the specific needs and requirements of OEM/ODM customers.

Customization options may include conveyor configuration, removal mechanism, weighing capacity, software functionality, user interface, and integration functionality.

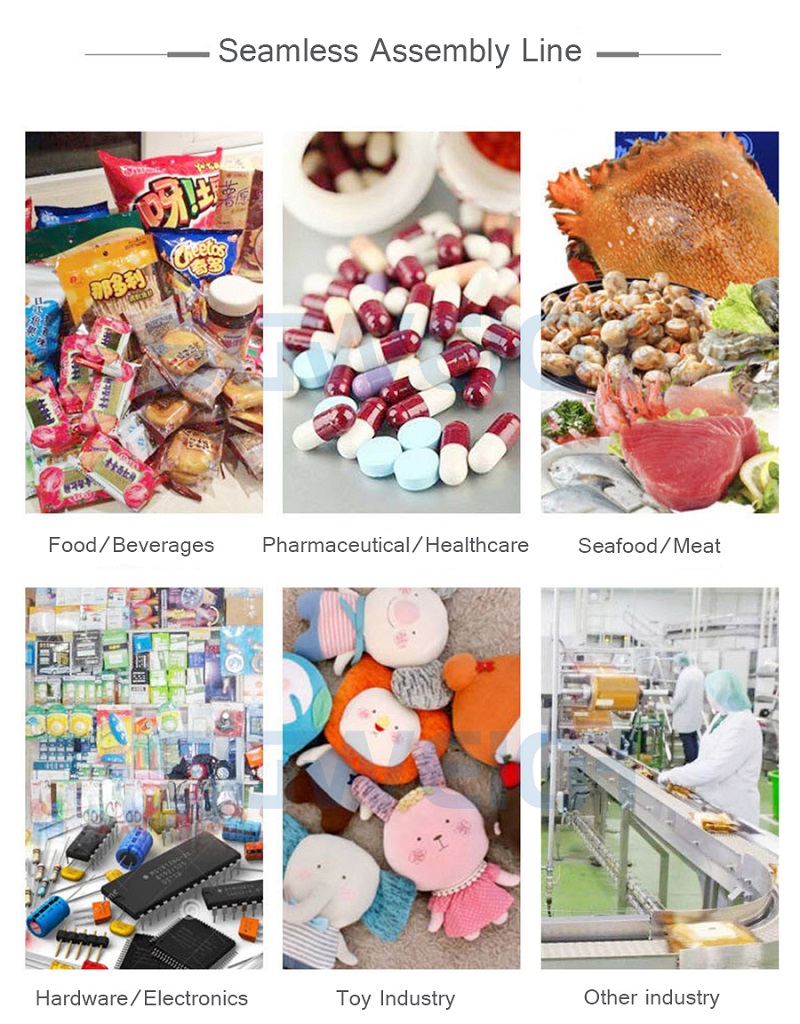

1. Aquatic products: fish, sea cucumber, abalone, lobster, oyster, crab, shellfish, etc

2. Poultry meat: chicken legs, chicken wings, duck legs, duck wings, white striped duck, various meat products, ham sausages

3. Agricultural and sideline products: fruits and vegetables

4. Medicinal materials: Cordyceps sinensis, Panax notoginseng, and other precious medicinal materials

5. Industrial products, automotive parts, precious metals

We are Shanghai Shigan Industrial Co., Ltd., an instrument expert headquartered in Shanghai, China. Since 2010, we have been specializing in the production of assembly line checkweighers and digital metal detectors. Over its 15 year history, our products have sold well in the European, American, and Southeast Asian markets, with over 90 countries in total over the years, especially favored by European and American countries. In addition to standard machines, our R&D team can also customize for you. Just tell us your needs and we will satisfy you. Our main products: automatic checkweighers, digital metal detectors, weighing labeling machines, checkweigher and metal detector combo, and etc,.

1. High quality materials: The plywood box is made of high-quality wood, which is sturdy, durable, and has good load-bearing capacity.

2. Fumigation treatment: The export fumigated plywood box has undergone strict fumigation treatment to ensure that it does not contain any harmful organisms and meets international export standards.

3. Quick connection design: The box adopts a quick connection design, which is easy to disassemble and assemble, saving time and reducing labor intensity.

4. Easy to open and reuse: The box design is simple, easy to open, and convenient for loading and unloading goods. Meanwhile, plywood boxes can be reused, reducing logistics costs.

5. Internal plastic film packaging: The box is packaged with plastic film to effectively protect the goods from salt, wind, or damage. In addition, plastic film has good sealing performance, which can prevent microbial invasion and ensure the safety of goods.

1. Equipment installation and debugging: The company provides detailed operation manuals and free operation training to ensure that customers can proficiently use the equipment.

2. Technical support: The company provides 24/7 technical support to solve problems encountered by customers during use.

3. Accessories supply: The company provides original accessories to ensure the quality and stability of the accessories.

4. Quality assurance: The company is responsible for the products sold, ensuring that the quality and performance of the equipment meet industry standards.

5. Warranty policy: One year warranty, lifetime repair, to solve customers' worries.

Related Products

Automatic Conveyor Check Weigher with Reject System

Food Bag Combo Machine of Checkweigher and Metal Detector

1500pcs/min High-precision Capsule Checkweigher

Online Food Beverage Industry Metal Detector

1kg Paper Bag Grain Rice Weight Control Checkweigher

Small Tea Bag Multi-column Checkweigher Supply Price

Hot Labels:meat,multi-level weight sorting machine,checkweigher,touch screen,weight grading solutions,manufacturer,supplier,factory,price

This metal detector + weight c...

View MoreLeveraging advanced load cell ...

View MoreThis auto checkweigher with du...

View MoreThis inline metal detector for...

View MoreThis sensitivity metal detecto...

View MoreThis high-speed boxed cigarett...

View More