A vertical capsules metal detector is a device used to detect whether metal impurities are mixed in materials passing through pipelines or conveyor belts. This type of digital metal detector for industrial is usually installed on the conveying path of materials, which can effectively monitor and prevent the impact of metal particles on product quality.

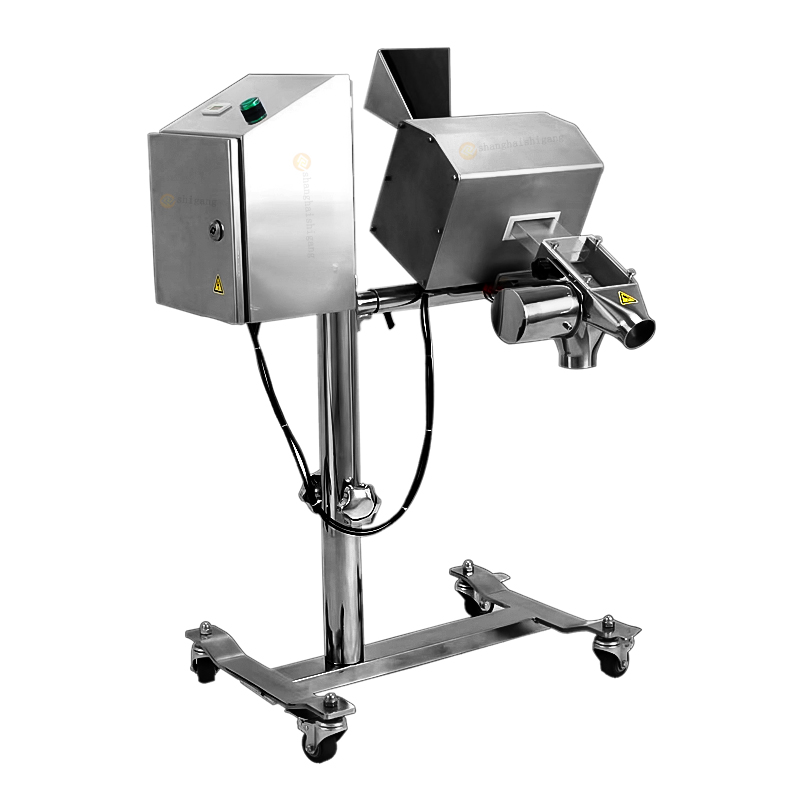

Loose Particle Capsules Metal Detector Vertical Metal Detection Machine for Industrial

A vertical capsules metal detector is a device used to detect whether metal impurities are mixed in materials passing through pipelines or conveyor belts. This type of digital metal detector for industrial is usually installed on the conveying path of materials, which can effectively monitor and prevent the impact of metal particles on product quality. For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

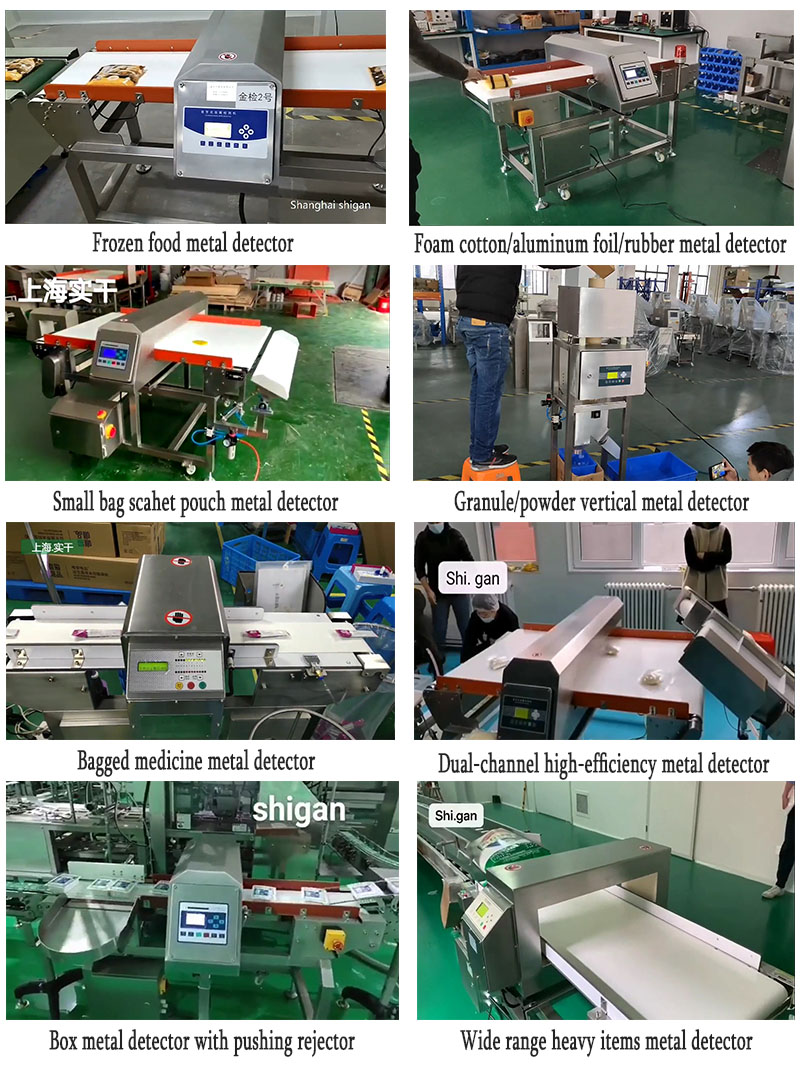

Vertical capsules metal detector photos

Type: SG-YJ60

Inter Height: H 770-930mm; Port size: φ76mm

Outer Height: H 770-860mm; Port size: φ51mm

Effective passing size: W70*H20mm

Output Capacity: 50w pcs/h

Detection sensitivity: φ Fe 0.4mm;φ SUS 0.6mm

Deadweight of machine: 75kg

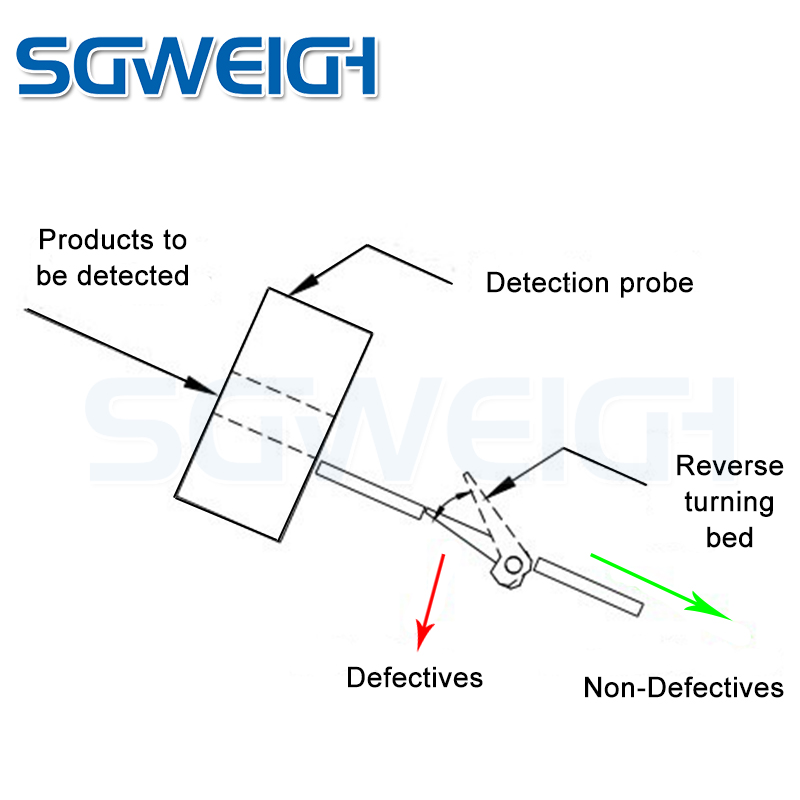

Rejection Way: Flip Culling

Working powder supply: 220v/110v, 50/60Hz

Dimension: 1115*550*(1280-1440)mm

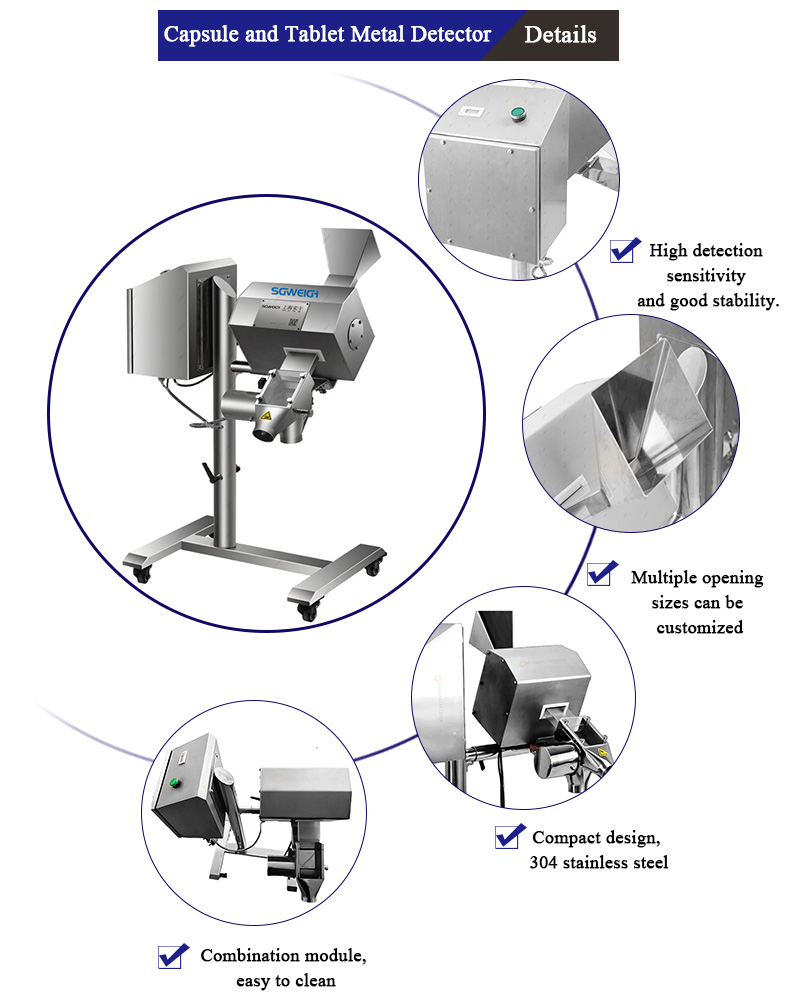

1. High sensitivity: able to detect very small metal impurities, ensuring product quality.

2. High stability: Vertical capsules metal detector can maintain stable detection performance under various working conditions, avoiding false alarms and omissions.

3. Easy to operate: The device has an intuitive operating interface, making it convenient for operators to set parameters and view detection results.

4. Strong adaptability: Vertical capsules metal detector can be applied to aluminum foil production lines with different thicknesses and speeds, meeting various production needs.

5. Intelligence: Equipped with automatic calibration, fault self diagnosis and other functions, improving the reliability and maintenance convenience of equipment.

As a key testing equipment on the production line, the capsules metal detector involves different fields. If the product specifications do not meet the requirements, please contact us by inquiry or chat with me to meet customization needs. We can also introduce the factory and machines to you through live streaming. Our team will tailor it for you.

Shanghai Shigan Industrial Co., Ltd. was established in 2010. It is a high-tech enterprise specializing in the research and development, production and sales of automatic checkweigher, digital metal detector. The company has been focusing on the development and sales of automatic checkweighers, digital metal detection equipment and other assembly line equipment for more than 15 years. It has become a well-known professional equipment manufacturer and service provider in the industry. Its main products include automatic checkweighers and digital metal detection equipment. , weighing and labeling machines, etc. The company attaches great importance to the cultivation of independent research and development capabilities and the construction of technical teams, and has formed a technical team with independent research and development capabilities, ensuring that the company can continuously launch new products that meet customer needs.

1: Lubrication drive device

2: Divide the machine into modules

3: Wrap the module with plastic film

4: Packaging modules into cardboard boxes

5: Making marks

If there are any special requirements, we will package according to your requirements.

1. Customer consultation and technical support: Provide customers with consultation services related to product use, repair, and maintenance, and answer any problems they encounter during operation and use.

2. Technical training: Provide training on product operation, maintenance, and repair to meet customer needs, ensuring that customers can use and maintain products correctly.

3. Accessory supply: Provide original accessories to ensure the quality and performance of the accessories and meet the needs of users.

4. One year warranty and lifelong maintenance

6. After sales service tracking: Track and provide feedback on the after-sales service process, timely understand customer needs and opinions, and continuously improve service quality.

Related Products

High Precision Assembly Line Empty Capsule Checkweigher

Inline Box Check Weigher For Food Industry Rejector

Big Bag Carton Metal Detector Conveyor Price

High Performance Bottle Rotary Checkweighers

Pharmaceutical Sample Checkweigher for Capsules

Strip Pack Multi Lane Checkweighers for Daily Necessities

Hot Labels: loose particle,capsules,metal detector,vertical,metal detection machine,industrial,price,manufacturer,supplier

The multi-lane checkweigher fo...

View MoreThe box check weigher with met...

View MoreThe digital soft gel capsules ...

View MoreThis capsule tablet checkweigh...

View MoreShampoo bag multi-lane checkwe...

View MoreBottle rotary weighing checkwe...

View More