Stable dynamic checkweigher is a device that realizes high-speed, high-precision weight detection and automatically sorts out light or heavy products under the dynamic conditions of the production line, thereby greatly improving product quality and optimizing the production process, thereby controlling costs, eliminating waste, Increased profits. Online check weighing machine can be used to detect all products on the production line, and comprehensively display production data such as production quantity, batch tracking, total weight, effective weight, and rejected weight.

Stable dynamic checkweigher is a device that realizes high-speed, high-precision weight detection and automatically sorts out light or heavy products under the dynamic conditions of the production line, thereby greatly improving product quality and optimizing the production process, thereby controlling costs, eliminating waste, Increased profits. Online check weighing machine can be used to detect all products on the production line, and comprehensively display production data such as production quantity, batch tracking, total weight, effective weight, and rejected weight.You are welcome to contact us at any time for further information.

Specification Parameter

Type SG-450

Weighing Range 0.05-20/30kg

Limited of product L: 500 W:450 H: 3-400mm

Accuracy ±1g

Division Scale 0.1g

Belt Speed 0- 40 m/min

Max Speed 40 pcs/min

Belt Width 450mm

Machine Weight 100kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

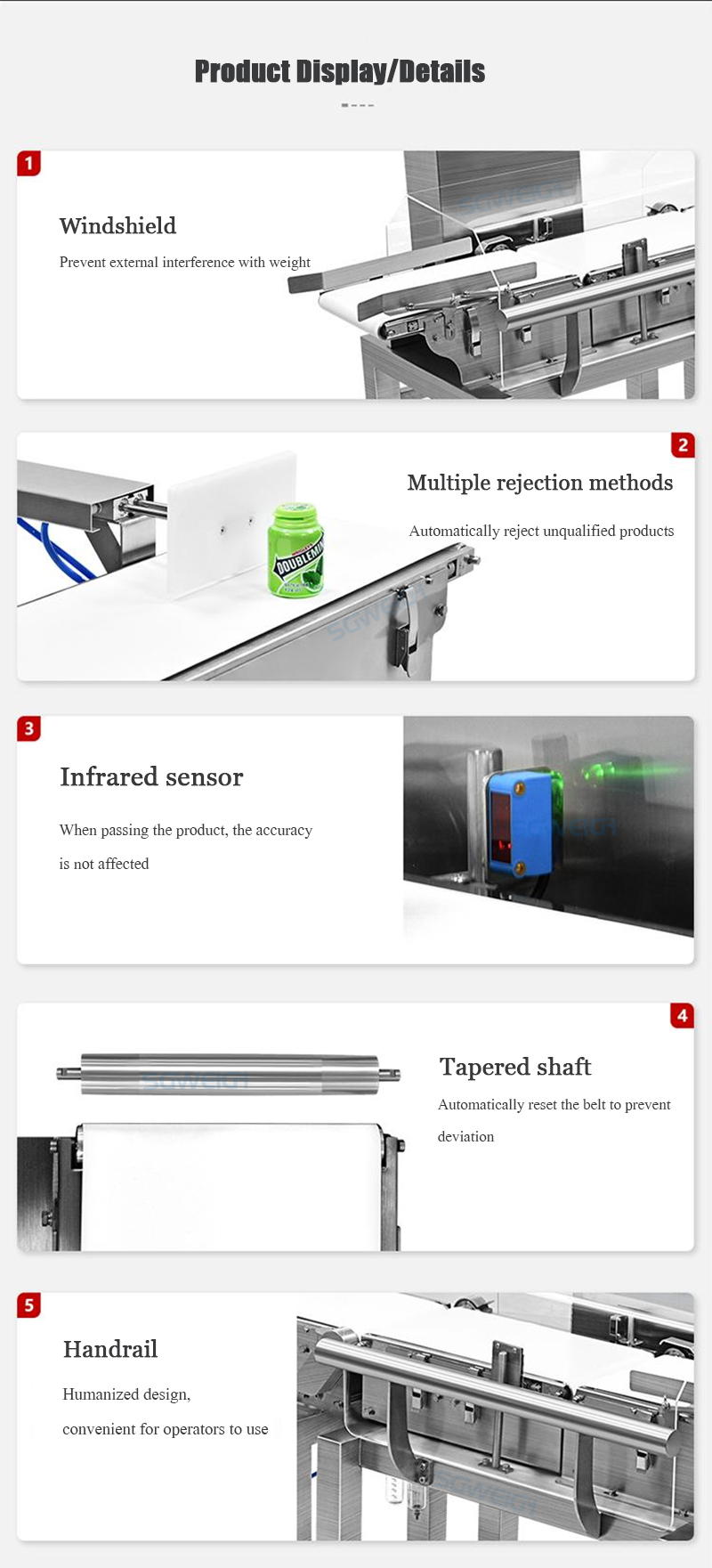

Main Advantages

1.Reinforced stainless steel frame, fully waterproof design

2.All contact parts are made of food-grade materials to ensure that the product will not be contaminated

3.The weight sorting machine can be customized according to the customer's specific application requirements: such as sorting grade, rejection device

4.Using high-precision sensors, high-speed digital signal processing technology

5.Dynamic weight automatic compensation technology, zero point automatic analysis and tracking technology

6.100 product presets, easy product editing and storage

7.Fast product switching and automatic adjustment of the sorting speed of corresponding products

8.USB mass storage, inspection records can be consulted at any time

9.The intuitive and easy-to-use man-machine interface minimizes the training time and cost of operators

Application

1) FCL inspection: missing parts, missing packages, missing boxes, missing bottles, short cans, missing bags, etc.;

2) Detection of underweight and overweight of packaged products; detection of missing accessories in the package, such as manuals, accessories, gifts, desiccants and other accessories.

Our Company

Shanghai Shigan Industrial Co., Ltd. is located in the beautiful scenery of Shanghai, China. It has been engaged in the production and development of assembly line packaging weighing equipment since 2010, and has obtained CE certification and a number of professional certificates. The company has always adhered to the business philosophy of "innovation, quality and efficiency" Provide you with perfect, high-quality products and services. Now our company's products have been sold all over the world, and have gained the trust and praise of countless customers!

Our main products are: automatic checkweighers, digital metal detectors, vertical packaging machines, premade pouch packaging machines, multi-head weighers, linear scales, weighing labeling machine and a series of assembly line packaging testing equipment.

After Sale Service

In line with the business tenet of "providing customers with satisfactory products and services", Shanghai Shigan Industrial Co., Ltd. solemnly promises: while ensuring the advancement, reliability, and stability of the equipment, it will continue to improve the quality of service, from sale to After-sales delivery, commissioning and opening, equipment maintenance and management, technical services, user technical training, etc., ensure that customers can get good services and make customers satisfied and assured.

1. Ensure that the equipment packaging meets the requirements of moisture-proof, rain-proof, rust-proof, anti-corrosion and earthquake-proof, and the identification is clear and correct, so that the goods can be delivered to the site safely and in time.

2. High-quality and fast technical services

In order to better ensure the normal operation of the equipment, answer questions raised by users in a timely manner, and help users solve problems, the company's maintenance center and local maintenance outlets are responsible for opening, maintaining and technical consulting services in various places. In the maintenance center, a full-time engineer is responsible for providing customers with free technical consulting services at any time.

3. Free commissioning and commissioning for users

The engineer is responsible for the installation, commissioning, opening and testing of on-site equipment.

Related Products

Cooked Food Conveyor Belt Metal Detector

Prevent Unqualified Products Weight Checker

Digital Metal Detection Machine

Capsule Tablet Checkweigher Machine

Food Checkweigher Manufacturer

Hot Labels:large capacity,agricultural,compound fertilizer,checkweigher, 15kg,stable,dynamic,check weighing machine

The multi-lane checkweigher fo...

View MoreThe box check weigher with met...

View MoreThe digital soft gel capsules ...

View MoreThis capsule tablet checkweigh...

View MoreShampoo bag multi-lane checkwe...

View MoreBottle rotary weighing checkwe...

View More