Automatic highly precise checkweigher is a high-speed, high-precision online checkweighing equipment, dynamic weight signal processing system, rich software, electronic and mechanical options, so that this series can meet the online checkweighing requirements of all walks of life. The modular design makes the operation and daily maintenance of this dynamic checkweigher solution series very simple. The product parts are easy to disassemble and clean with water.

Automatic highly precise checkweigher is a high-speed, high-precision online checkweighing equipment, dynamic weight signal processing system, rich software, electronic and mechanical options, so that this series can meet the online checkweighing requirements of all walks of life. The modular design makes the operation and daily maintenance of this dynamic checkweigher solution series very simple. The product parts are easy to disassemble and clean with water. Imported electrical components are used, which have waterproof performance and simple operation surface. It can store the parameters of 100 kinds of materials with different weight specifications, which is convenient for operation and use.Our product specifications and sizes are rich, various styles, welcome to contact us for quotation information.

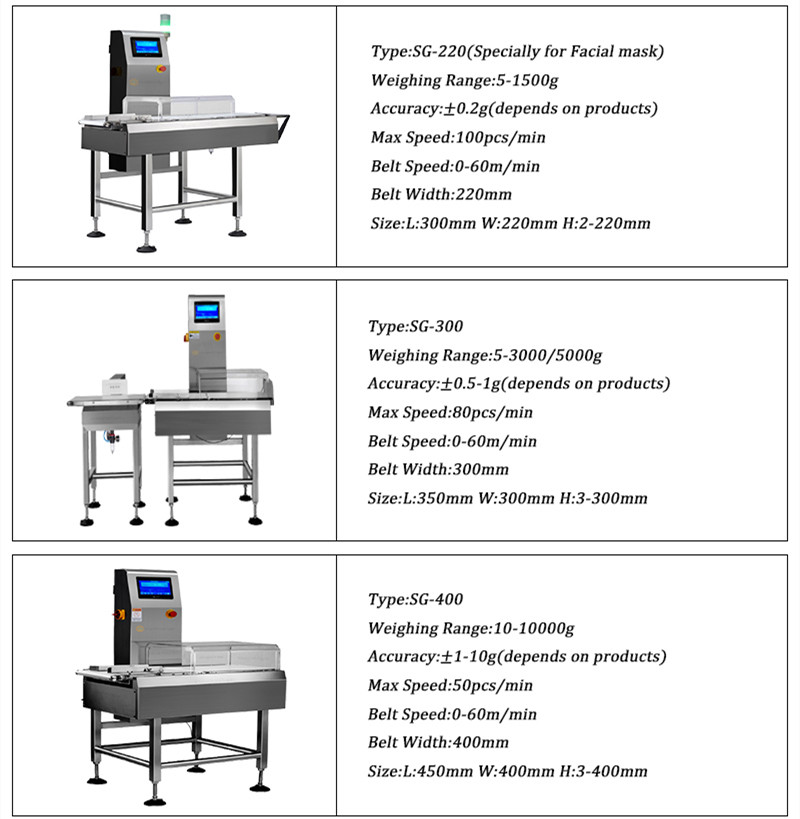

Automatic dynamic checkweigher list type

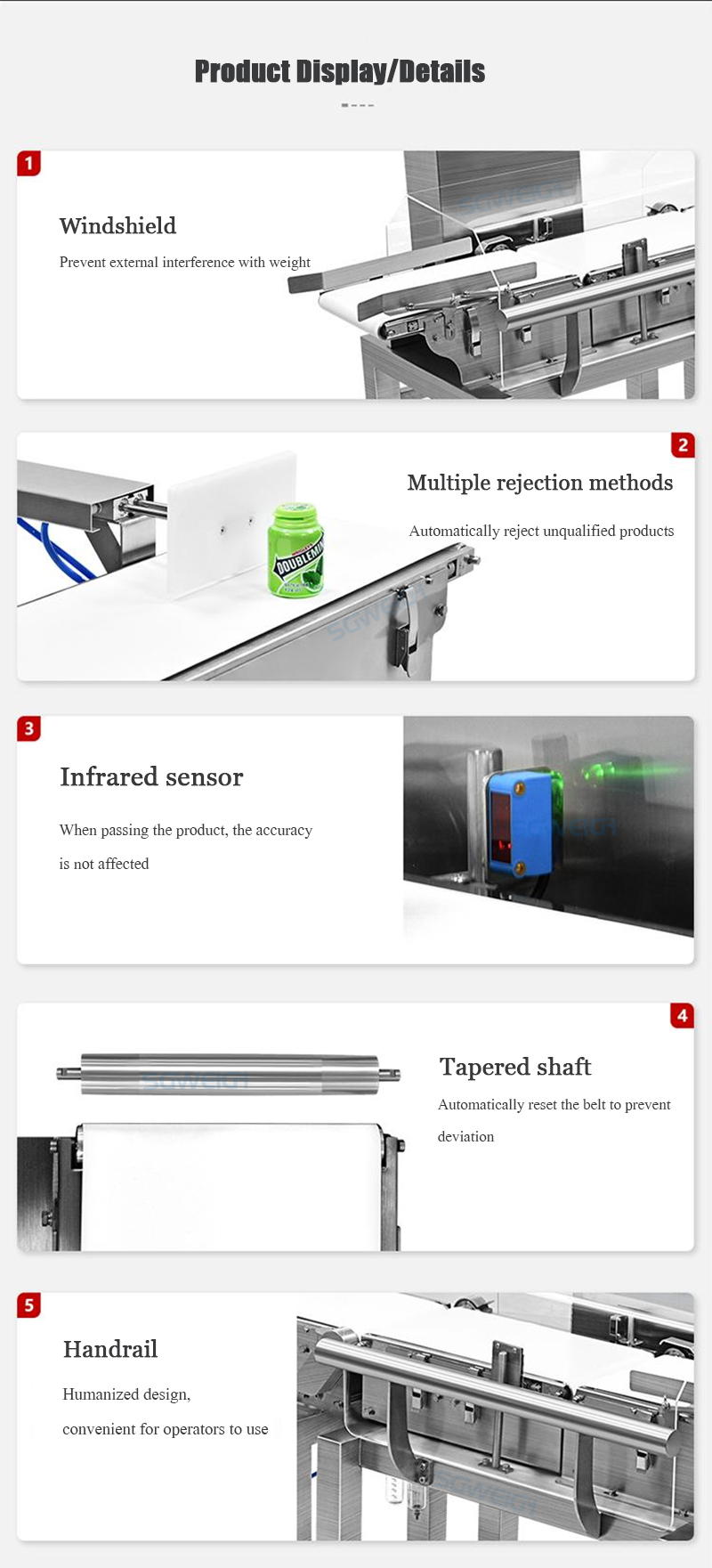

1.Reinforced stainless steel frame, fully waterproof design

2.All contact parts are made of food grade materials to ensure that the product will not be contaminated

3.The weight sorter can be customized according to the customer's specific application requirements: e.g. sorting grades, reject devices

4.Using high-precision sensors, high-speed digital signal processing technology

5.Dynamic weight automatic compensation technology, zero point automatic analysis and tracking technology

6.100 product presets for easy product editing and storage

7.Fast product switching and automatic adjustment of the sorting speed of the corresponding product

8.USB mass storage, inspection records can be consulted at any time

9.Intuitive and easy-to-use HMI minimizes operator training time and costs

The automatic checkweigher provides the following three solutions for users in industries such as food and beverage/pharmaceutical health care/daily chemical light industry/raw material biology/hardware parts/aquaculture products:

1. Unqualified net content detection: underweight/overweight detection of product packaging such as bags, bags, boxes, cans, bottles, etc.;

2. Detection of missing parts in the whole box: detection of missing bags/bags/boxes/fills/bottles in the whole box, detection of missing bags/boxes in the whole package, detection of missing and missing packaging;

3. Integrated solution of weighing detection and metal detection: mainly to help manufacturers detect unqualified net content, missing products, products containing metal impurities and other unqualified products, and automatically remove defective products, improve product qualification rate and quality, and ensure Product integrity.

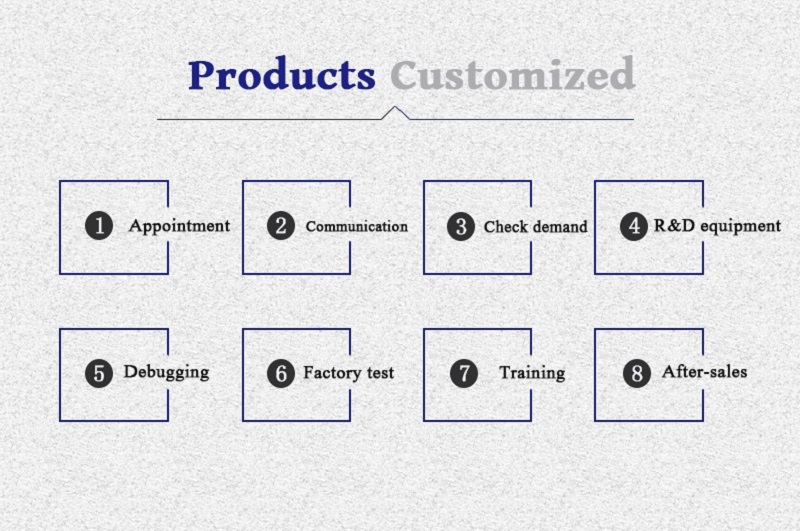

Our professional engineers will rigorously evaluate factors such as production line characteristics, specifications and environment, and design the most suitable checkweigher solution for your production line to meet the different needs of various complex production lines.

Shanghai Shigan Industrial Co., Ltd. is located in the beautiful Shanghai, China. It has been engaged in the production and development of assembly line packaging and weighing equipment since 2010, and has obtained CE certification and a number of professional certificates. To provide you with perfect, high-quality products and services. Now our company's products have been sold all over the world, and won the trust and praise of countless customers!

Our main products are: automatic checkweigher, digital metal detector, vertical packaging machine, prefabricated bag packaging machine, multi-head scale, linear scale, packaging machine and a series of assembly line packaging testing equipment

Packing Detail:

Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

Delivery Detail :

Shipped in 20 days after payment

1. Service tenet: fast, decisive, accurate, thoughtful and thorough

2. Service goal: service quality to win customer satisfaction

3. Service efficiency: If the equipment fails within the warranty period or outside the warranty period, our company will arrange maintenance personnel to provide maintenance services for customers within 24 hours after receiving the notice.

4. Service principle: The product warranty period is one year. During the warranty period, our company will repair the damaged parts due to quality reasons for free. If the parts are damaged outside the warranty period, only the cost will be charged for the provided accessories. If it is due to human factors The equipment damage caused by our company, the accessories repaired or provided by our company are calculated at the cost price.

Related Products

Prevents Underfilled or Overfilled Packages Checkweigher

Intelligent Industrial Weight Inspection Machine

Alarm Light Check Weigher Scales With Roller

Mutilhead Weigher For Packing Machine

1kg small semi automatic Weighing Filling Machine Powder Filler

in line check weigher system checkweigher pharmaceutical

Hot Labels:automatic check weigher,checkweighers list,highly precise,fast,checkweigher solutions,inspection systems,factory,cheap,Ukraine

The multi-lane checkweigher fo...

View MoreThe box check weigher with met...

View MoreThe digital soft gel capsules ...

View MoreThis capsule tablet checkweigh...

View MoreShampoo bag multi-lane checkwe...

View MoreBottle rotary weighing checkwe...

View More