High speed capsule tablet sampling checkweigher specifically used for drug production. Its main function is to weigh and test capsule and tablet products during the drug production process, automatically select and remove products that do not meet quality standards. The weight detection range of capsule tablet sample checkweighers is usually between 10-2000 mg, with a maximum detection accuracy of 0.5-1.0 mg.

High Speed Capsule Tablet Sampling Checkweigher 10mg Sample Checkweigher

High speed capsule tablet sampling checkweigher specifically used for drug production. Its main function is to weigh and test capsule and tablet products during the drug production process, automatically select and remove products that do not meet quality standards. The weight detection range of capsule tablet sample checkweighers is usually between 10-2000 mg, with a maximum detection accuracy of 0.5-1.0 mg. If you have any questions or comments, please feel free to contact us.

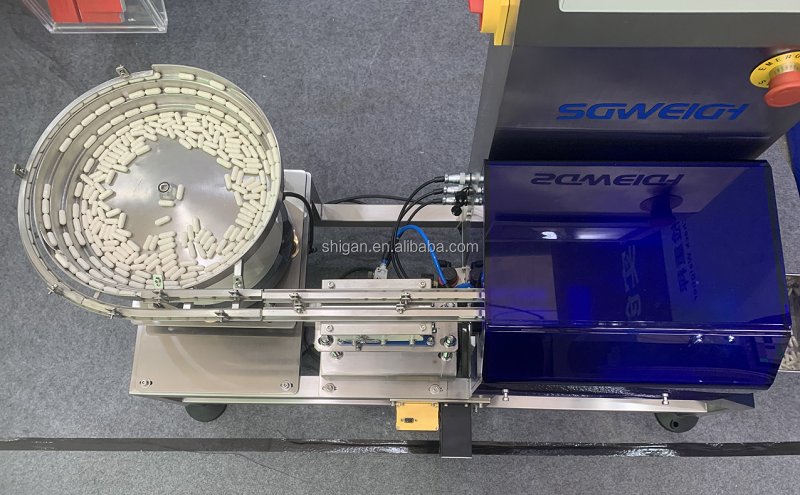

High speed capsule tablet sampling checkweigher photos

Type SG-DJ10

Weighing Range 20-2000mg

Limited of product L: 100 W: 100 H: 2-150mm

Accuracy ±1mg Depends on product

Division Scale 1mg

Each Channel Speed 100 pcs/min

Machine Weight 80kg

Power Supply AC -220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

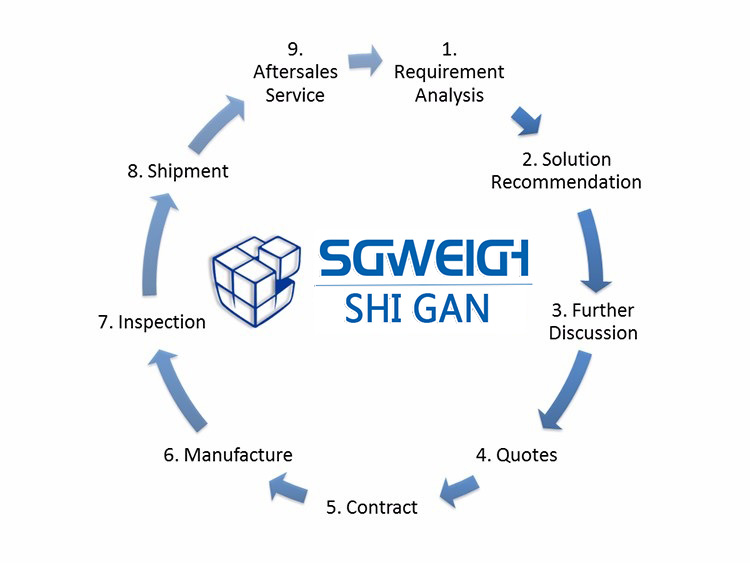

1st step: Customer has showed his special requirements.

2nd step: We try to understand the conception and pattern from customer with simple draft or refer picture.

3rd step: Making the conceptive CAD drawing based on communication and understanding.

4th step: Making the detail and 3D drawing agter fixed the design and other details.

5th step: Offer the quotation after confirm the design,material and surface treament.

6th step: Making the sample for approval.

7th step: Testing installation after demo mock up.

8th step: Big production delivery and service after sales.

1. High precision weighing: The high speed capsule tablet sampling checkweigher adopts advanced sensors and weighing control modules, which can achieve high-precision weight detection and ensure that the difference in drug loading is controlled within the allowable range.

2. Quick automatic calibration: The high speed capsule tablet sample checkweigher can quickly complete the automatic calibration of the channel, reduce manual operations, improve work efficiency, and ensure the accuracy of daily weighing.

3. Strong adaptability: One set of molds can adapt to different types of hollow capsules, including various extended and DB types, without the need for frequent mold replacement, simplifying the operation process.

4. Large capacity silo: Equipped with a large capacity silo, it can reduce the number of feeding times for operators and improve production efficiency during large-scale full inspection.

5. Reducing the impact of static electricity: The material handling mechanism adopts 316L stainless steel, which can effectively eliminate the static electricity carried by some hollow capsules themselves and reduce the impact of symmetry accuracy.

6. Easy to clean and maintain: The weighing platform can be quickly and safely removed, making it easy to clean and disinfect, ensuring the hygiene and durability of the equipment.

7. Online monitoring and fault detection: The capsule tablet sample checkweigher is equipped with an online detection function for sensor abnormalities, which monitors the health status of all channels in real time, discovers and solves problems in a timely manner.

8. Compliant with regulatory requirements: Drug regulatory authorities have increased their sampling efforts for drug quality, and capsule sampling scales can help pharmaceutical companies strictly control quality, avoid being identified as inferior drugs due to differences in packaging volume exceeding the limit, and ensure that enterprises do not suffer losses.

9. Intelligent control: The capsule tablet sample checkweigher can be linked with the formulation packaging machine to automatically adjust the measurement structure based on the detection results, achieving intelligent production control.

10. Eliminating non-conforming products: Optional elimination structure can automatically eliminate non-conforming products, improve product quality, and save costs.

The capsule tablet sample checkweigher is mainly used for weighing and testing drug capsules and tablet products to ensure that product quality meets regulatory requirements. By conducting spot checks, it is possible to avoid the entire batch of drugs being identified as inferior due to individual capsule or tablet weight differences exceeding the standard, thereby reducing the risk for the enterprise.

1.14 years of experience in capsule tablet sample checkweigher manufacturing.

2. Over ten years of technical team building, with a high-quality team consisting of over 30% of professional technical personnel. Product design updates and rich experience in personalized product industry requirements.

3. A professional foreign trade team with a sales team of over 20 people, each employee with rich market sales experience, providing high-quality pre-sales online communication services.

4. A professional after-sales service team with a 1-year warranty period, willing to establish long-term cooperative relationships with every customer.

5. We cooperate with multiple logistics companies to safely and quickly deliver goods to customers, minimizing their logistics costs.

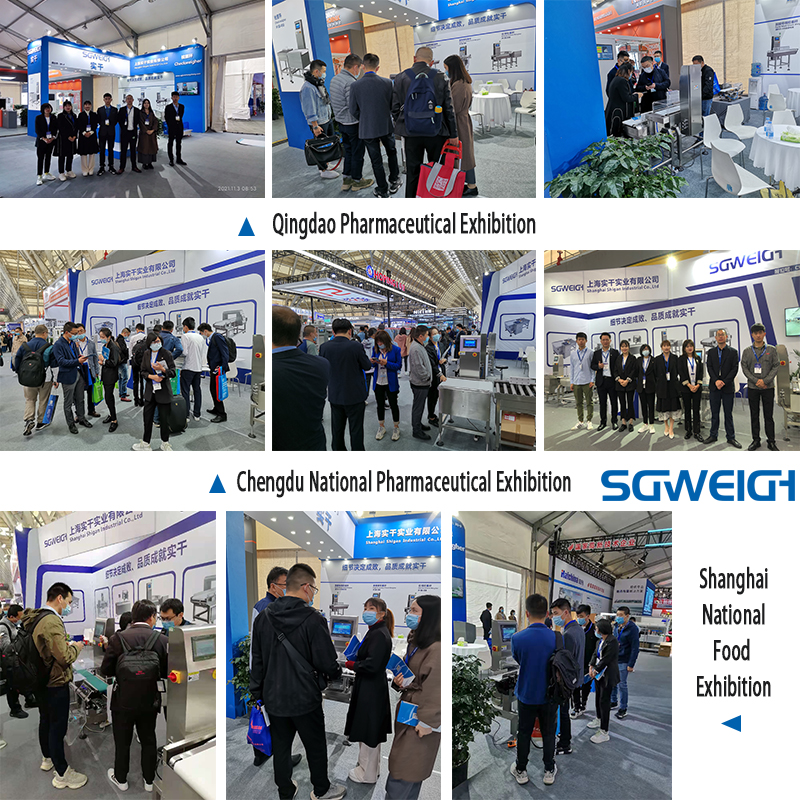

6. Regularly participate in large-scale industry exhibitions in various regions and have the ability to negotiate cooperation with regional partners.

1> Attach safety labels, tighten screws, clean, lubricate, and prevent rust;

2> Disassemble into packaging pieces;

3> Wrap tightly with plastic film;

4> Fixed in plywood box

5> Forklift entering container

Suitable for long-distance land and sea transportation, for safe loading and unloading to the destination, we recommend choosing full container transportation.

12 Months Guarantee

★ 12 months free main parts change (Please return the damaged parts by airmail)

★ Overseas engineers available (You only have to pay part of the freight)

Customization

All our machines can be customized , according to your product's features and your workshop environment, or your production line.

After-sales Service Provided

Engineers availbale to provide after-sales service overseas in order to help customers solve technical problems.

Related Products

20mg High Precision Capsule Tablet Sample Checkweigher

SG-220 Standard High Performance Checkweigher

Inline Checkweigher for Bottles Pouches Medicine

Industrial Paper Box Checkweigher and Labeling Machine

20kg Bag Flour Roller Conveyor Checkweigher

Freeze Dried Chicken Breast Multi-level Sorting Checkweigher

Hot Labels: high speed,capsule tablet sampling checkweigher,10mg,capsule tablet checkweigher,factory,supplier,manuafacturer,price

The multi-lane checkweigher fo...

View MoreThe box check weigher with met...

View MoreThe digital soft gel capsules ...

View MoreThis capsule tablet checkweigh...

View MoreShampoo bag multi-lane checkwe...

View MoreBottle rotary weighing checkwe...

View More