The dynamic capsule sampling checkweigher can perform online weight checks on products such as capsules and tablets to ensure that the product loading meets the standards. The high precision capsule sampling checkweigher can dynamically weigh and classify products on automated production lines online, detect non-conforming products, and achieve product classification through backend classification and elimination structures.

High Precision Capsule Sampling Checkweigher for Production Line Price

The dynamic capsule sampling checkweigher can perform online weight checks on products such as capsules and tablets to ensure that the product loading meets the standards. The high precision capsule sampling checkweigher can dynamically weigh and classify products on automated production lines online, detect non-conforming products, and achieve product classification through backend classification and elimination structures.

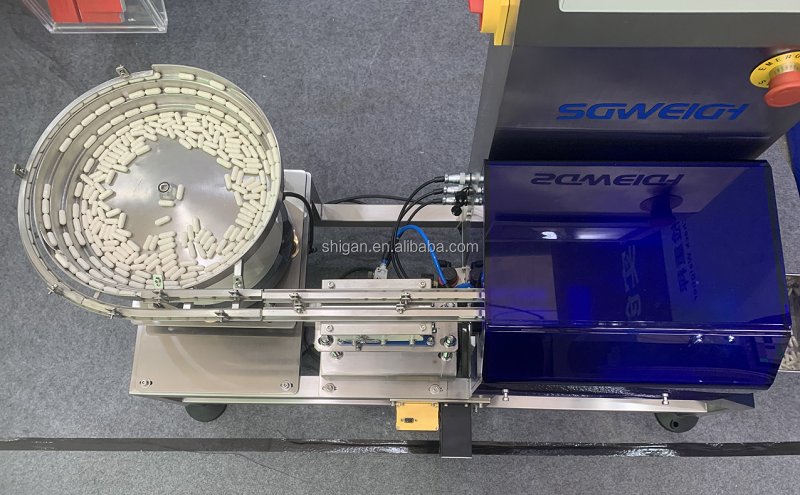

Dynamic capsule sampling checkweigher pictures

1. High precision: The dynamic capsule sampling checkweigher adopts high-precision sensors, which can achieve accurate weight detection of capsules and tablets up to 0.1mg, ensuring product quality.

2. Automation: The dynamic capsule sampling checkweigher adopts an automated operating system, which can automatically perform timed sampling and reject unqualified products, reducing manual intervention and improving detection efficiency.

3. Intelligence: The device has data storage and statistical functions, can monitor the production process in real time, analyze product quality trends, and can be connected to internal systems of the enterprise to achieve remote monitoring and management.

4. Flexibility: The dynamic capsule sampling checkweigher can adjust parameters such as detection frequency and range according to production needs, meeting the requirements of different production lines.

5. Easy to maintain: The equipment has a simple structure, is easy to disassemble and clean, and reduces maintenance costs.

6. Safety: The dynamic capsule sampling checkweigher adopts an open channel design to ensure the safety of operators.

Type SG-DJ10

Weighing Range 20-2000mg

Limited of product L: 100 W: 100 H: 2-150mm

Accuracy ±1mg Depends on product

Division Scale 1mg

Each Channel Speed 100 pcs/min

Machine Weight 80kg

Power Supply AC -220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

Shanghai Shigan can tailor a machine that meets the needs of customers and specific scenarios. Meet the personalized needs of customers in terms of functionality, performance, appearance, etc.

Shanghai Shigan IndustrialCo., Ltd. is a modern enterprise located in Shanghai, China, engaged in mechanical design, research and development, manufacturing, and sales of various automatic checkweighers and metal detection machines for over 14 years. Our product positioning is to design first-class machines. We adhere to the marketing philosophy of "quality first, customer first" and the work philosophy of "honest service, continuous improvement". Our machines are sold both domestically and internationally, selling well in Asia, Southeast Asia, the Middle East, Europe, Africa, South America, and other regions, receiving high praise from customers. Our main products: automatic checkweigher, conveyor belt metal detector, automtic weighing labeling machine, and etc,.

1> Attach safety labels, tighten screws, clean, lubricate, and prevent rust;

2> Disassemble into packaging pieces;

3> Wrap tightly with plastic film;

4> Fixed in plywood box

5> Forklift entering container

Suitable for long-distance land and sea transportation, for safe loading and unloading to the destination, we recommend choosing full container transportation.

✔ Integrity: We adhere to honest management, always guided by customer needs, and provide high-quality products and services

✔ Quick response: We have a professional after-sales service team that responds to customer needs in real time, ensuring that problems are resolved in a timely manner

✔ Customized services: Based on customer needs, provide personalized customization solutions to meet the diverse needs of different customers

✔ Quality assurance: From raw materials to finished products, we strictly control every production process to ensure product quality

✔ Technical Support: We provide comprehensive technical support, including product installation, usage training, and maintenance, to ensure that customers have no worries at all

✔ Improve after-sales service: We promise high-quality after-sales service, including free maintenance during the warranty period, regular after-sales follow-up, etc., to safeguard our customers

✔ Innovative R&D: We have an experienced R&D team dedicated to product innovation and technological research and development, providing customers with more competitive products

✔ Strict production: We follow strict production processes and quality management systems to ensure stable and reliable product quality

✔ Win win cooperation: We seek to establish long-term and stable cooperative relationships with customers, develop together, and achieve win-win outcomes

Related Products

Reagent Bottles Rotating Weighing Checkweigher

SG-220U Online Dynamic Box Check Weigher Machine

Cosmetic Checkweigher Metal Detector Combo

Capsule High-precision Vertical Metal Detection Machine

20-25 kg Large-range Bag Checkweigher

Multi-level Weight Sorting Machine for Bagged Bread Food

Hot Labels:high precision,capsule,tablet,sampling,checkweigher,production line,price,factory,manufacturer,supplier

The multi-lane checkweigher fo...

View MoreThe box check weigher with met...

View MoreThe digital soft gel capsules ...

View MoreThis capsule tablet checkweigh...

View MoreShampoo bag multi-lane checkwe...

View MoreBottle rotary weighing checkwe...

View More