Automatic checkweigher provides automatic weighing machine and packaging product weighing detection solutions for food, beverage, pharmaceutical, daily chemical and other industries, suitable for missing parts detection, missing packaging detection, net content unqualified detection; online automatic rejection of unqualified products, Comprehensively improve production quality.

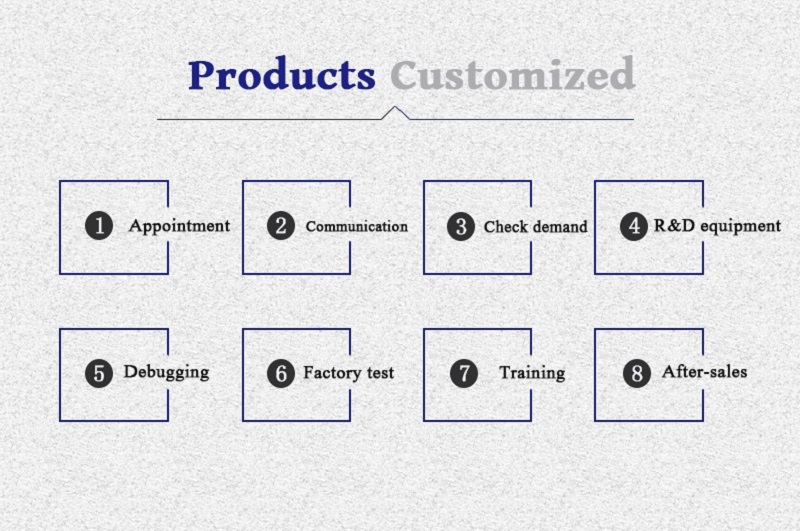

Automatic checkweigher provides automatic weighing machine and packaging product weighing detection solutions for food, beverage, pharmaceutical, daily chemical and other industries, suitable for missing parts detection, missing packaging detection, net content unqualified detection; online automatic rejection of unqualified products, Comprehensively improve production quality. At the same time, our company can provide customized good quality checkweigher and other automatic mechanical equipment according to the user's production and application environment requirements.Our product specifications and sizes are rich, various styles, welcome to contact us for quotation information.

Main Advantages

1. High adaptability to the equipment environment.

2. Very friendly operation interface.

3. The parameters can be modified at any time without the need for the weight sorting machine to suspend the sorting.

4. Up to 200 product presets can store hundreds of thousands of data records to meet the complex needs of customers.

5. Rich peripheral resources make it easy to interconnect with other devices.

6. Fast dynamic weighing algorithm software technology enables the entire system to maintain high detection accuracy even in high-speed operation.

Specification parameter

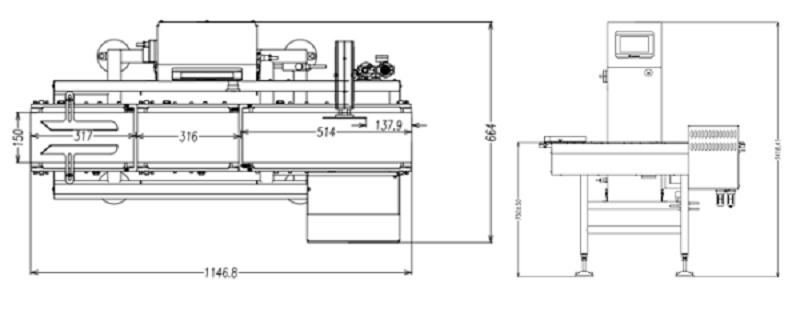

Type SG-150

Weighing Range 3-500g

Limited of product L: 200 W:150 H: 3-200mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 65 m/min

Max Speed 150 pcs/min

Belt Width 150mm

Machine Weight 60kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

Application

1. Underweight detection and overweight detection of packaged products; detection of missing accessories in the package, such as instructions, accessories, gifts, desiccants and other accessories.

2. FCL detection: missing parts detection, missing package detection, missing box detection, missing bottle detection, missing tank detection, missing bag detection, etc.

3. USB data storage interface, which can transfer report data to PC for analysis and printing; parameter setting password protection, only managers operate.

Good Quality Checkweigher Details

Our professional engineers will rigorously evaluate factors such as production line characteristics, specifications and environment, and design the most suitable checkweigher solution for your production line to meet the different needs of various complex production lines.

Company Profile

Shanghai Shigan Industrial Co., Ltd. is a high-tech innovative technology enterprise specializing in the research and development, production and sales of automatic checkweighers.

The company has a high-quality weighing instrument R&D and sales team, relying on profound technical precipitation and extensive market demand, with scientific and rigorous design, management, and manufacturing processes to provide customers with stable performance, practical, convenient, beautiful and affordable. High-quality weighing products and perfect weighing solutions

After Sale Service

In the spirit of pursuing high-quality products and customer satisfaction, Shanghai Henggang Company solemnly promises you the principle of preferential price, thoughtful service and reliable product quality.

1.Product quality commitment:

(1). There are quality records and testing data for the manufacture and testing of products.

(2). For the inspection of product performance, we sincerely invite users to inspect the whole process and performance of the product in person. After the product is confirmed to be qualified, it will be packaged and shipped.

2. the product price commitment:

(1). Under the same competitive conditions, our company will sincerely provide you with a preferential price on the basis of not reducing the technical performance of the product or changing the product components.

3. Delivery time commitment:

(1). Product delivery time: as far as possible according to user requirements, if there are special requirements, it needs to be completed in advance, and strive to meet user needs.

Related Products

Dynamic Check Weigher Machine Food Medicine Price

Multi-head Weighing Packing Machine Production Line

Automatic Checkweigher Factory With Cheap Price

High Speed Checkweigher For Bottle Rejector

Tea Quantitative Packaging Machine Price

Barreled Cased Products Check Weigher Conveyor

Hot Labels:good quality,check weigher,stick,pack,pharmaceutical,machinery,checkweigher

The digital soft gel capsules ...

View MoreThe multi-lane checkweigher fo...

View MoreShampoo bag multi-lane checkwe...

View MoreBottle rotary weighing checkwe...

View MoreThe quantitative capsule table...

View MoreStable heavy carton check weig...

View More