The enterprise introduces the automatic checkweigher into the production line, which can carry out high-speed and high-precision weight detection on all packaged products on the line. If no judgment is made, the unqualified products will be prepared and eliminated. Dynamic checkweighers can detect all passing items without exception.

The enterprise introduces the automatic checkweigher into the production line, which can carry out high-speed and high-precision weight detection on all packaged products on the line. If no judgment is made, the unqualified products will be prepared and eliminated. Dynamic checkweighers can detect all passing items without exception.Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

Specification parameter

Type SG-300

Weighing Range 5-3000g/5000g

Limited of product L: 350 W:300 H: 3mm

Accuracy ±0.5-1g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 80 pcs/min

Belt Width 300mm

Machine Weight 80kg+44kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

Main Advantages

1) Efficient and economical: multi-stage sorting and automatic weighing, instead of labor, improve efficiency;

2) Strong versatility: the standardized structure of the whole machine and standardized man-machine interface can complete the weighing of various materials

3) Multi-level expansion: 2-12 levels of sorting can be customized according to customer needs;

4) Clear and sensitive: imported high-definition color touch screen, a variety of voice screens, the information is clear at a glance;

5) Professional and easy to use: professional checkweigher system, rich in functions, easy to operate, and various statistical formats of checkweighing data to meet the needs of various production data;

6) Rich expansion: a variety of sorting methods are available, and various expansion equipment can be installed according to customer needs;

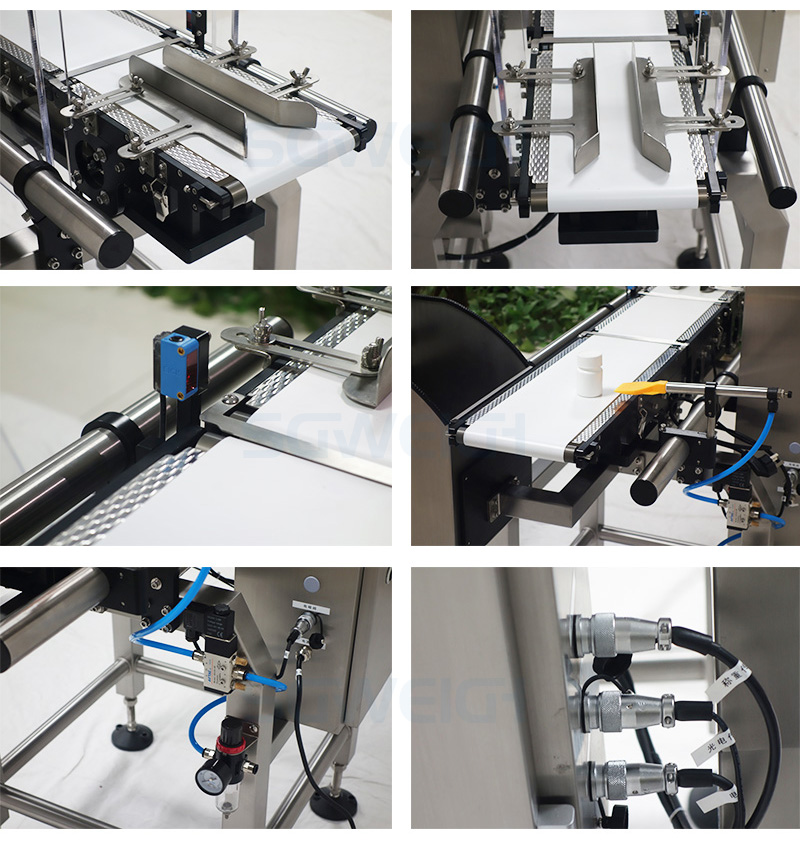

7) Convenient maintenance: fast dismantling structure design, easy to clean and maintain;

8) Beautiful and durable: 304 stainless steel, or high-strength aviation aluminum material body; to ensure the stability of long-term operation.

Application

1. Check the weight of the products one by one on the production line, and sort the qualified products, those with insufficient weight, and those with excessive weight to prevent defective products from leaving the factory.

2. According to the standard weight of the product, the excess or insufficient quantity of the product in the box or packing box is sorted, and the product that meets the standard quantity is delivered.

3. The multi-level sorting scale is based on the standard weight value of the product, and the abnormal state of the sorting product state will only leave the factory with excellent products.

4. For assembled products, the standard weight value of the product shall prevail to measure and confirm whether spare parts and decorations are missing.

5. This equipment is connected with other auxiliary devices to increase the efficiency of inspection and effectively manage production.

Our Customers

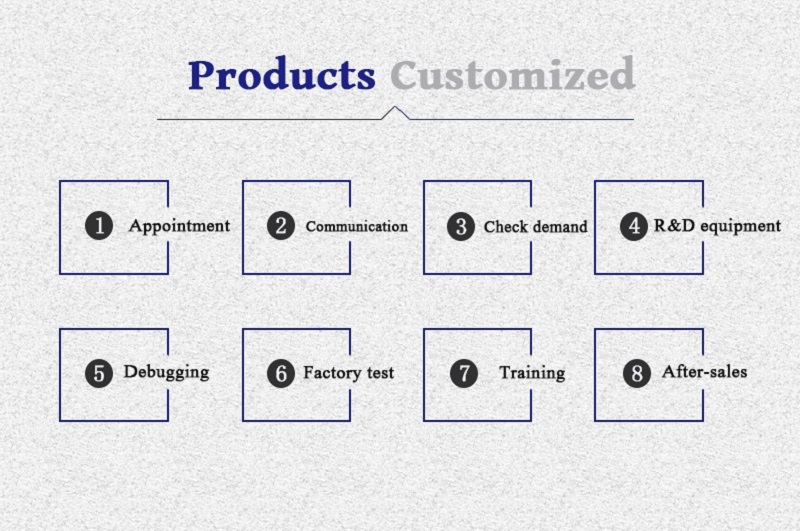

Customized

1st step: Customer has showed his special requirements.

2nd step: We try to understand the conception and pattern from customer with simple draft or refer picture.

3rd step: Making the conceptive CAD drawing based on communication and understanding.

4th step: Making the detail and 3D drawing agter fixed the design and other details.

5th step: Offer the quotation after confirm the design,material and surface treament.

6th step: Making the sample for approval.

7th step: Testing installation after demo mock up.

8th step: Big production delivery and service after sales.

About Us

About our company

1. Founded in 2010.

2. Shanghai high-tech enterprise.

3. With more than 10 years of experience in the field of checkweighers and our own factory, we can provide you with the most suitable items for your needs.

4. There are 6-8 international machinery exhibitions every year.

5. Supply OEM/ODM manufacturing.

6. Multiple engineers to ensure quality/service.

7. As a manufacturer and trader, we have a good quality and price control on our products.

8. Products are exported to more than 40 countries such as the United States, Canada, Mexico; Australia, New Zealand; Saudi Arabia, Italy, Spain; France, Poland, Israel, Russia, South Korea; Thailand, Indonesia, Malaysia, the Philippines, etc.

After Sale Service

A. Pre-sale:

1. Provide real quotations for customers according to customer requirements, and record feedback in a timely manner if customers have special requirements;

2. Sign a standardized product order contract to clarify responsibilities and other related matters;

3. Provide one-year free warranty, life-long maintenance service, and be responsible for debugging the product before delivery;

B. After sales:

1. If the customer's product fails, we will provide you with a solution as soon as possible;

2. During the warranty period, product maintenance is free. If the warranty period is exceeded, maintenance can also be provided. If parts are replaced, the product parts will be provided at the cost price.

Related Products

High Speed Checkweigher For Bottle Rejector

Tea Quantitative Packaging Machine Price

Large Capacity Automatic Checkweigher For Barreled Cased

Weight Sort Food Checkweigher Machine

Industrial Automatic Check Weighing Machine With Alarm

Chicken Wing Weight Multi-level Checkweigher

Hot Labels:automatic,checkweigher,factory,cheap,price,conveyor,check weigher,food,weight checker

The multi-lane checkweigher fo...

View MoreShampoo bag multi-lane checkwe...

View MoreBottle rotary weighing checkwe...

View MoreThe quantitative capsule table...

View MoreStable heavy carton check weig...

View MoreThe food multistage weight sor...

View More