Automatic checkweigher in the high-speed flow production line, the checkweigher can realize high-speed and high-precision weight detection, and select products that are too light or too heavy. So as to improve product quality and optimize product process. To control costs and increase profits for enterprises. Bottle check weigher can detect products on the production line, track product quantity, weight and other data, eliminate substandard products, and distribute products to areas.

Automatic checkweigher in the high-speed flow production line, the checkweigher can realize high-speed and high-precision weight detection, and select products that are too light or too heavy. So as to improve product quality and optimize product process. To control costs and increase profits for enterprises. Bottle check weigher can detect products on the production line, track product quantity, weight and other data, eliminate substandard products, and distribute products to areas.Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

| Specification parameter | |

| Type | SG-150H |

| Weighing Range | 3-500g |

| Limited of product | L: 100 W:150 H: 3-150mm |

| Accuracy | ±0.1g Depends on product |

| Division Scale | 0.1g |

| Belt Speed | 0- 90 m/min |

| Max Speed | 160 pcs/min |

| Belt Width | 150mm |

| Machine Weight | 60kg |

Due to the particularity of bottled products, it is necessary to not only ensure the accuracy and high speed of the detection, but also ensure that the bottled products do not fall over during the weight detection, so as to avoid product damage. Our company has developed a clamping conveyor matched with a checkweigher, which can efficiently avoid product damage and ensure the accuracy and speed of detection.

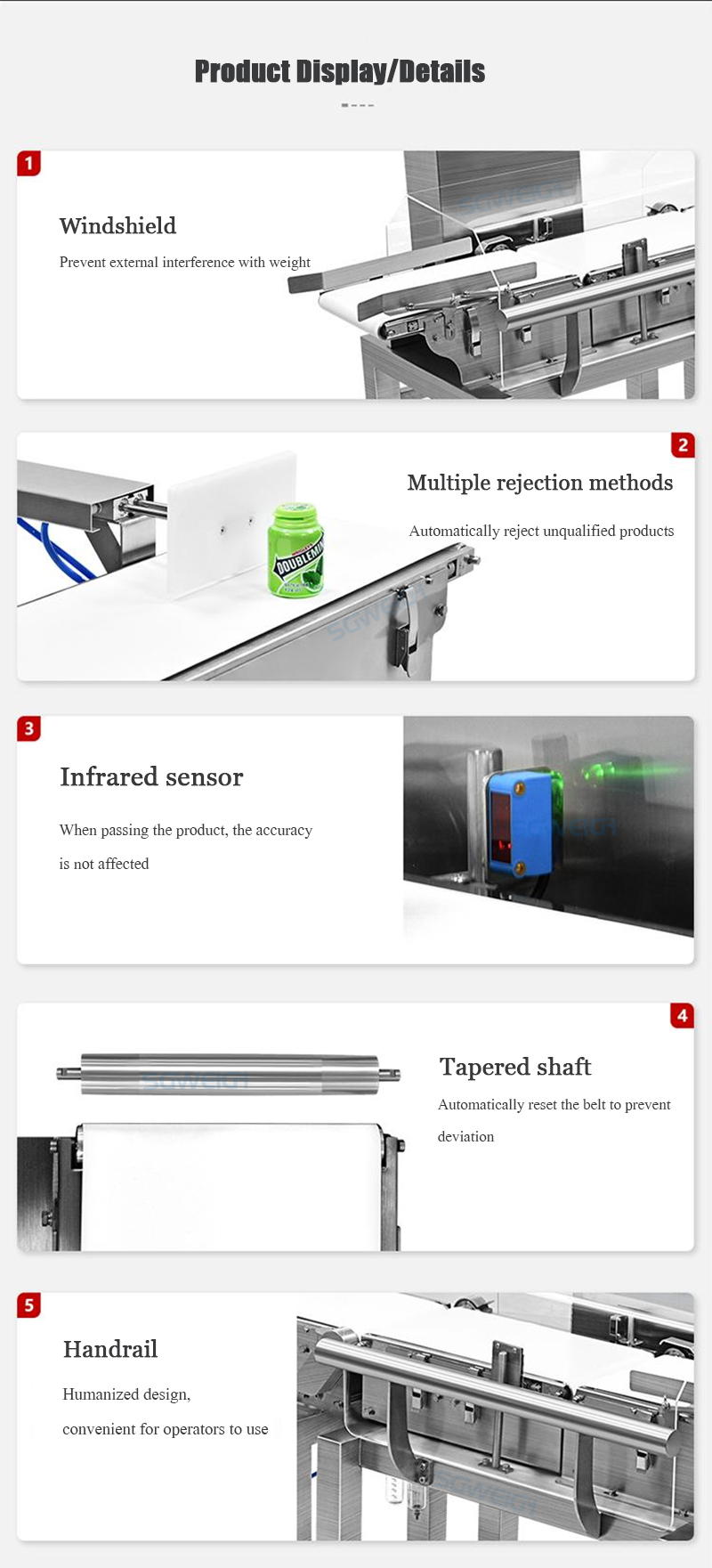

Main Advantages

1. 10-inch color touch screen; like a smartphone, easy to operate.

2. Quick belt replacement system; with buckle design, it is very easy to clean the belt.

3. Up to 10 quick menus, seamless docking to change products, to achieve non-stop product switching.

4. Inquiry and printing of unqualified products

5. Provide feedback signals of production trends, adjust the packaging accuracy of upstream packaging machines, improve user satisfaction and reduce costs.

6. The core components are imported accessories to ensure the stability of the equipment operation

7. The independent processing plant makes the equipment at the same level with lower cost and the most affordable price.

8. The domestic high-quality shunt removal device prevents the product from falling down during the sorting process and spills the material, and ensures the integrity of the detected object.

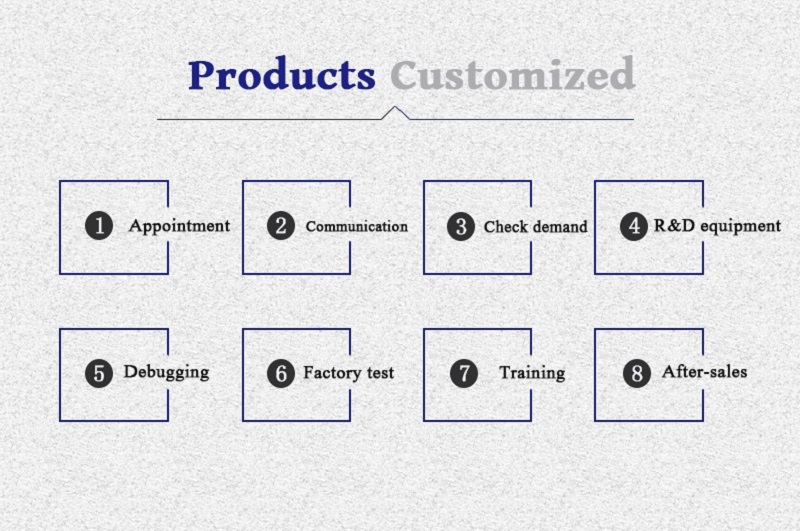

Customized

The product demonstrating may not perfectly meet your requirements,our philosophy is to customize your real need.

To minimizing idle capacity and function. To supply you performance and cost balanced products. Following are the factors shall be taken into account during customization:

1,Products to be packed

2,Container to be filled, type and specification.

3,Capacity requirement

4,Automation requirement

5,Protection requirement

6,Other specific requirement

Application

1. Recheck the product weight to ensure the net content of the product

2. Single product weight measurement to achieve classification by weight range

3. Feedback adjustment of packaging weight, saving the amount of loading

4. Deletion Detection

5. Yield statistics, easy production management

About Us

Shanghai Shigan Industrial Co., Ltd. is located in the beautiful Shanghai, China. It has been engaged in the production and development of assembly line packaging and weighing equipment since 2010, and has obtained CE certification and a number of professional certificates. To provide you with perfect, high-quality products and services. Now our company's products have been sold all over the world, and won the trust and praise of countless customers!

Our main products are: automatic checkweighers, digital metal detectors, vertical packaging machines, prefabricated bag packaging machines, multi-head scales, linear scales, packaging machines and a series of assembly line packaging testing equipment

After Sale Service

A. Pre-sale:

1. Provide real quotations for customers according to customer requirements, and record feedback in a timely manner if customers have special requirements;

2. Sign a standardized product order contract to clarify responsibilities and other related matters;

3. Provide one-year free warranty, life-long maintenance service, and be responsible for debugging the product before delivery;

B. After sales:

1. If the customer's product fails, Shanghai will solve the problem for you as soon as possible, and other places will provide you with solutions as specific;

2. During the warranty period, product maintenance is free. After the warranty period, maintenance can also be provided. If the accessories are replaced, the product accessories will be provided at the cost price.

Related Products

Good Quality Checkweigher Stick Pack Machinery

Check Weigher Machine Food Medicine Price

Intelligent 14-head Multi-head Weigher for Dried Fruit

Conveyor Check Weigher For Food Weight Checker

High Speed Checkweigher For Bottle Rejector

Multi-Head Weigher Micro Multi-head Combination Scale

Hot Labels:bottle,check weigher scale,conveyor,automatic,check weigher,checkweigher,touch screen

The carton packaged food check...

View MoreThe industrial check weigher f...

View MoreMini high accuracy checkweighe...

View MoreThe coffee beans bag checkweig...

View MoreThe core part of the high-prec...

View MoreFood package multi-level sorti...

View More