The dynamic logistics checkweighers can be used to control the qualification rate of packaged products, detect whether the packaging weight meets the specifications, and determine whether the number of items placed in the box meets the requirements. Automatic checkweigher roller conveyor has excellent versatility, providing accurate weighing results, and are designed to have durability and the highest reliability in humid and dry environments.

50kg Dynamic Logistics Bulk Weight Inspection Checkweigher Roller Conveyor

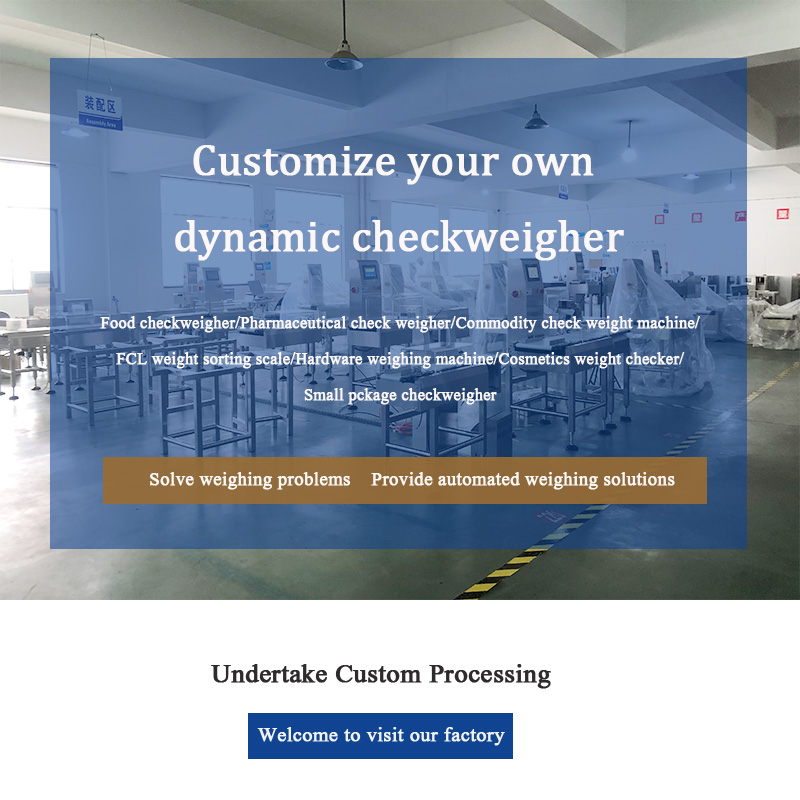

The dynamic logistics checkweighers can be used to control the qualification rate of packaged products, detect whether the packaging weight meets the specifications, and determine whether the number of items placed in the box meets the requirements. Automatic checkweigher roller conveyor has excellent versatility, providing accurate weighing results, and are designed to have durability and the highest reliability in humid and dry environments. Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

Dynamic logistics checkweighers photos

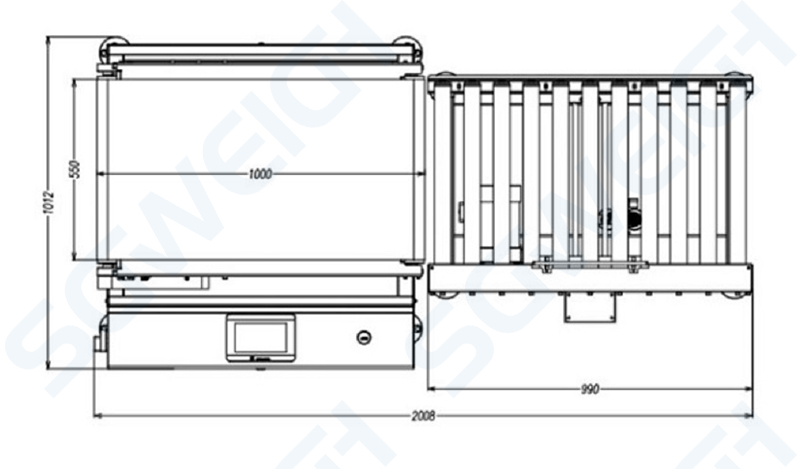

Type SG-450

Weighing Range 0.05-25kg

Limited of product L: 550 W:450 H: 3-400mm

Accuracy ±5/10g

Division Scale 1g

Belt Speed 0- 60 m/min

Max Speed 40 pcs/min

Belt Width 450mm

Machine Weight 40kg+70kg+45kg

Power Supply AC 110/220V ±10% 50HZ

Power 400W

Main Material SU304 stainless steel

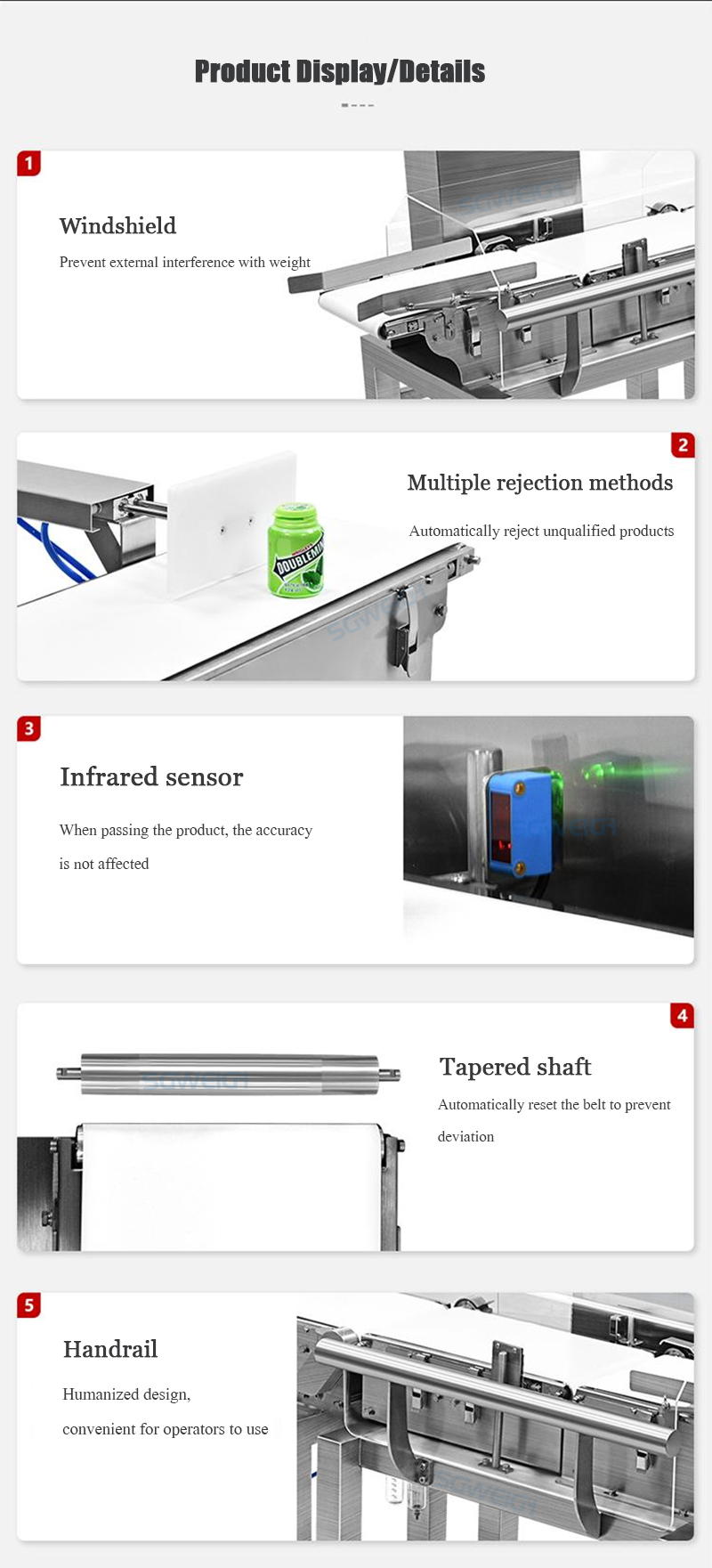

1.High performance and maximum efficiency.

2.Large load range with extreme precision.

3.Designed for demanding production environments.

4.Flexible and efficient product handling.

5.Low maintenance costs.

6.Improve production line efficiency. Equipment efficiency across the entire line is improving.

7.The accuracy of the weighing machine ensures that customer interests are not affected.

8.Reduce potential sampling errors and long-term labor costs.

9.Improve product quality to meet customers' strict needs.

10.Cost savings increase product profits.

1. Depending on the external dimensions of the tested product and the operating environment of the equipment, there may be slight differences in the accuracy of the testing speedometer

2. All specifications and parameters can be customized according to requirements

Full box inspection: missing parts inspection, missing package inspection, missing box inspection, missing bottle inspection, missing can inspection, missing bag inspection, etc.

The dynamic logistics checkweigher is widely used in industries such as food, pharmaceuticals, beverages, health products, daily chemicals, agricultural and sideline products, hardware, toys, electronics, digital, printing, etc.

Shanghai Shigan Industrial Co., Ltd. was established in 2010 and is a high-tech enterprise specializing in the research and development, production, and sales of automatic checkweigher equipment. The company has been focusing on the development and sales of assembly line equipment such as automatic checkweigher s and digital metal detector equipment for more than 15 years, and has become a well-known professional equipment manufacturer and service provider in the industry. Its main products include automatic checkweighers, digital metal detector, weighing and labeling machines, etc. The company attaches great importance to cultivating independent research and development capabilities and building a technical team. It has formed a technical team with independent research and development capabilities, ensuring that the company can continuously launch new products that meet customer needs.

The Delivery Date: After receiving the payment, the delivery date will be within 15-30 working days

Packaging: Protective film + wooden case

Logistics: Air, sea or express (DHL, etc.)

The Freight: The cost of transport depends on the destination, mode of transport and the weight of the goods

Pay: T/T, Western Union, paypal

Consultation and evaluation: Understand the customer's requirements, production processes, and quality control objectives, and determine the most suitable weighing scale solution for their specific needs.

Product demonstration: Intuitively understand the operation of the equipment and directly evaluate its performance.

Installation and debugging: After purchase, the weighing scale is installed and debugged by trained technicians to ensure its correct operation and seamless integration into the customer's production line.

Technical Support: Provide continuous technical support to solve any questions, problems, or maintenance needs that may arise during the operation of the weighing scale.

Warranty scope: 1-year warranty, lifetime repair.

We aim to provide customers with the right solutions, support, and peace of mind throughout the entire lifecycle of their equipment, ensuring that the weighing scales meet their needs and provide long-term value.

Related Products

Capsule Tablet Sample Checkweigher For Medical

Large Load Heavy Carton Metal Detection Machine

Medicine Food Multi-stage Weight Sorting Machine Checkweigher

Customized 2/4/6/8/10 Multi-lane Checkweigher

Online Automatic Checkweigher for Boxed Medicines

Mini Dynamic High Speed Check Weigher Supply

Hot Labels: 50kg,dynamic,logistics,bulk,weight inspection,checkweigher,roller,conveyor,factory,price,manufacturer

The high-speed flat weighing l...

View MoreThe hi-speed bottle conveyor c...

View MoreThe food sauce paste pipeline ...

View MoreThe dynamic logistics checkwei...

View MoreThe online checkweigher for bo...

View MoreA vertical capsules metal dete...

View More