The hi-speed bottle conveyor checkweigher can automatically and quickly weigh and sort items. Through precise weighing, the weighing scale helps to ensure consistency in product weight, improve product quality, meet customer needs and industry standards. The automatic food bottle checkweigher weighing scale can usually adjust the weighing range and sorting standards to meet the production needs of different products, and has good flexibility.

Automatic Food Bottle Conveyor Checkweigher Machine Hi-speed Check Weight Machine Factory

The hi-speed bottle conveyor checkweigher can automatically and quickly weigh and sort items. Through precise weighing, the weighing scale helps to ensure consistency in product weight, improve product quality, meet customer needs and industry standards. The automatic food bottle checkweigher weighing scale can usually adjust the weighing range and sorting standards to meet the production needs of different products, and has good flexibility. Our product specifications and sizes are rich, various styles, welcome to contact us for quotation information.

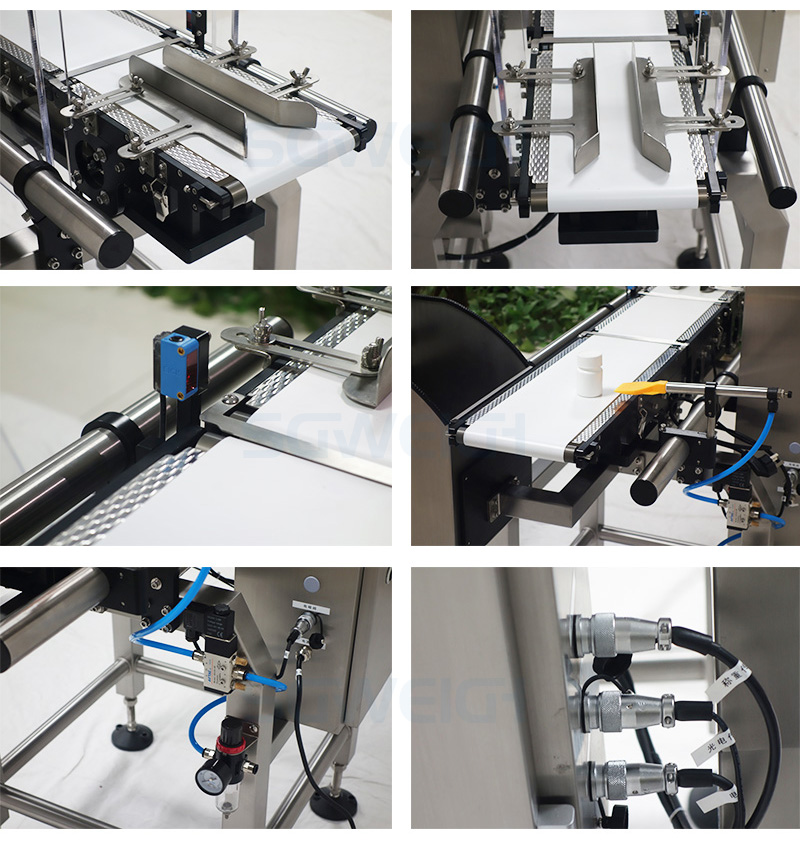

Hi-speed bottle conveyor checkweigher photos

1. Easy to integrate: adjustable height, modular design

2. Durable and sturdy structure: stainless steel 304

3. Easy to use: The touch screen operating system is easy to use and comes with user password protection

4. Easy to clean: The detachable belt is easy to disassemble for cleaning and setting.

5. Variable speed: The speed can be configured according to the application

6. High speed and accuracy: Equipped with advanced sensors and weighing sensors, equipped with ultra fast processors, it has excellent accuracy and speed

7. Zero tracking: manual and automatic calibration to improve accuracy

8. Report and Data Export: Built in - Real time report, can be exported as an Excel file, and can store production data for 1 year in a USB drive

9. Connectivity: Standard port for data export and connection to PC

10. Self learning: No calibration required, the system will find the best settings for the product. Can configure up to 2000 product settings

11. Different detection modes: default mode, static mode, and power-saving mode

12. Fault report: The system can detect and report the faulty parts of the system, making it easier to diagnose problems

13. Output ports: RS-485 and RS-232, capable of connecting printers and label machines

Type SG-150

Weighing Range 3-500g

Limited of product L: 200 W:150 H: 3-200mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 150 pcs/min

Belt Width 150mm

Machine Weight 80kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

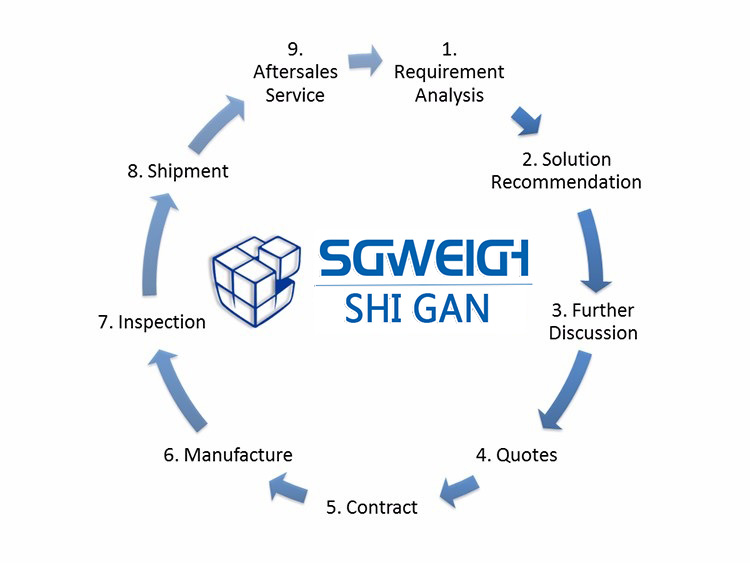

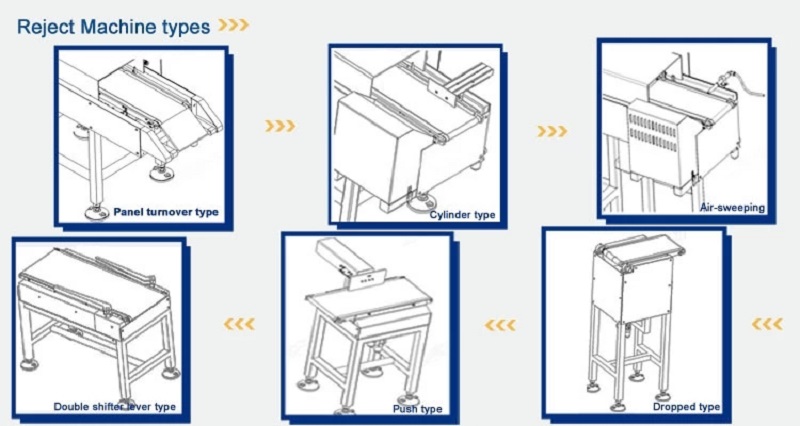

Based on the user assembly line and equipment application space, Shanghai Shigan provides customized services to ensure that the automatic checkweigher machine meets the actual production needs. The removal methods include alarm prompts, lever removal, push rod removal, air blowing removal, and other methods. Different weighing and removal methods are used according to the size and characteristics of the product.

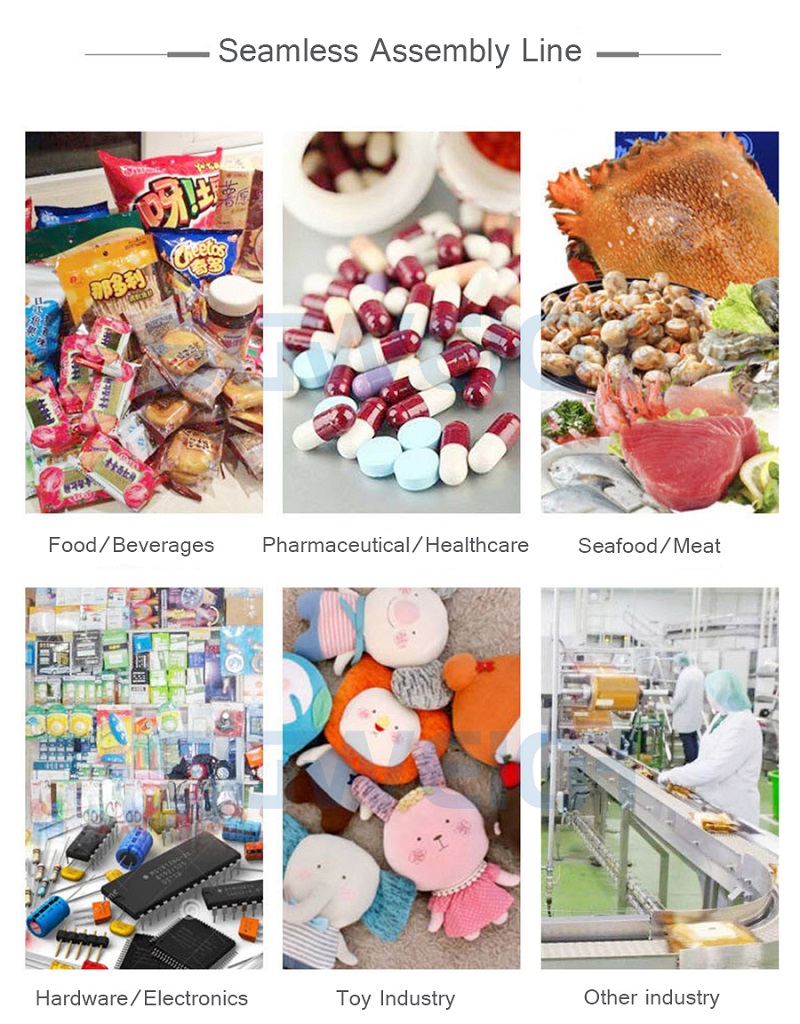

Hi-speed bottle conveyor checkweighers are widely used in various industries such as food, pharmaceuticals, beverages, health products, daily chemicals, agricultural and sideline products, hardware, toys, electronics, digital, printing, etc. Bottle checkweigher is currently an important intelligent testing equipment for reliable automatic weighing and quality inspection in assembly lines.

Shanghai Shigan Industrial Co., Ltd. is located in Shanghai, China and has been a professional manufacturer of automatic checkweighers, digital metal detectors for over 15 years. We have our own factory, and since its establishment, our company has been committed to the new technology field of automatic checkweighers, digital metal detectors. Now, we have formed a special competitive market based on advanced technology. We have obtained the CE certificate. Our products enjoy a good reputation for their quality, reliability, and efficiency. To assist professional clients in marketing, we also provide OEM services and customized machine designs.

1: Lubrication drive device

2: Divide the machine into modules

3: Wrap the module with plastic film

4: Packaging modules into cardboard boxes

5: Making marks

If there are any special requirements, we will package according to your requirements.

1. Customer consultation and technical support: Provide customers with consultation services related to product use, repair, and maintenance, and answer any problems they encounter during operation and use.

2. Technical training: Provide training on product operation, maintenance, and repair to meet customer needs, ensuring that customers can use and maintain products correctly.

3. Accessory supply: Provide original accessories to ensure the quality and performance of the accessories and meet the needs of users.

4. One year warranty and lifelong maintenance

6. After sales service tracking: Track and provide feedback on the after-sales service process, timely understand customer needs and opinions, and continuously improve service quality.

Related Products

Multi-level Weight Sorting Checkweigher for Food Pharmacy

Long Packaged Coffee Bars Multi-lane Checkweigher

Dynamic Pill Capsule Metal Detector Machine

Rotary Weighing Bottle Checkweigher With Turntable

Seafood Online Checkweigher with Metal Detector Combo

Chili Sauce Honey Paste Pipeline Metal Detector

Hot Labels: automatic,food,bottle,conveyor,checkweigher machine,hi-speed,check weight machine,factory,manufacturer,price

The high precision capsule che...

View MoreThe bag box bottle checkweighe...

View MoreThe vertical industrial partic...

View MoreHigh precision online checkwei...

View MoreThe high-speed flat weighing l...

View MoreThe hi-speed bottle conveyor c...

View More