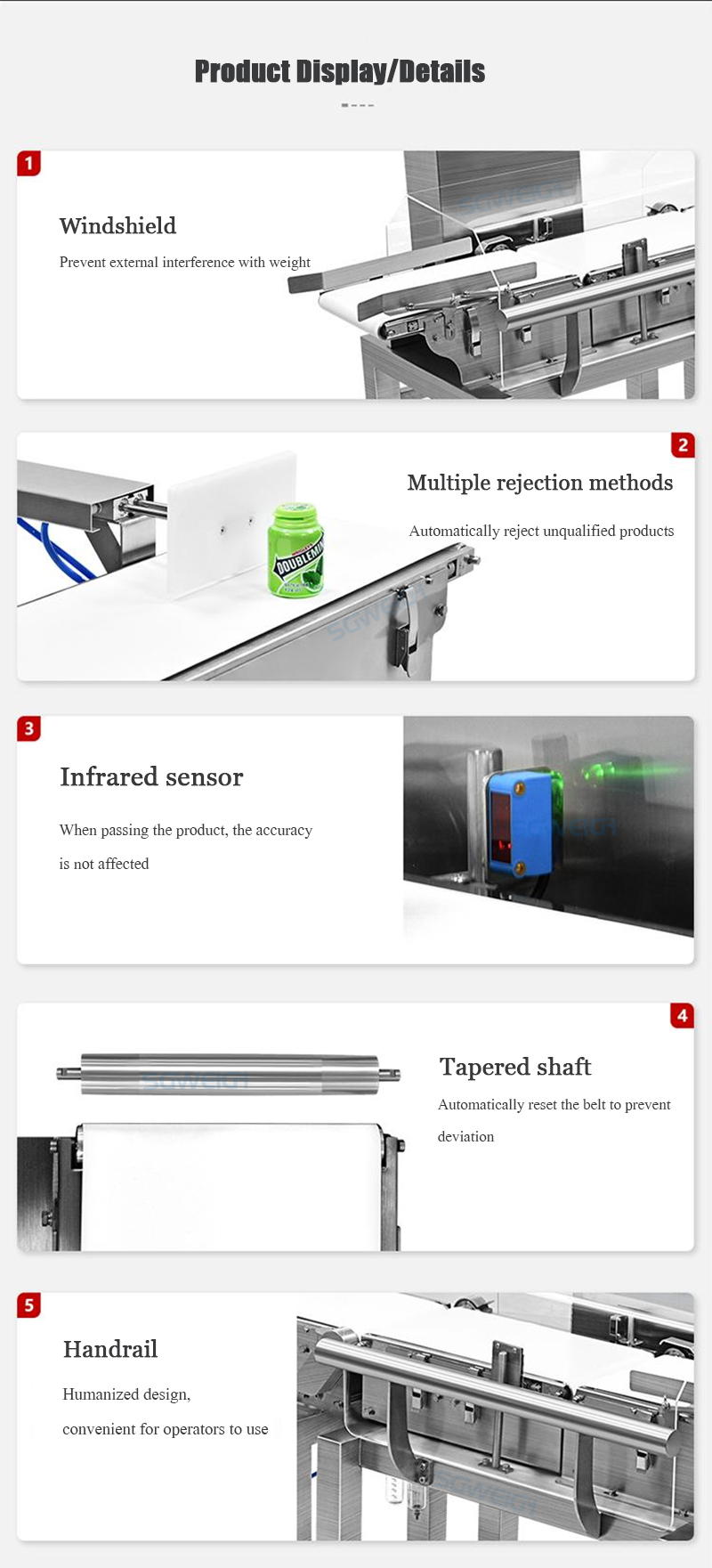

The assembly line checkweigher detects all products on the production line with high speed and high precision, and solves the problem of detecting products with "light" and "small" specifications. The automatic checkweigher is made of all 304 stainless steel, which is easy to clean and maintain. The processing technology is cut and polished by imported equipment, which is smooth and beautiful, stable on the ground, and easy to install.

The assembly line checkweigher detects all products on the production line with high speed and high precision, and solves the problem of detecting products with "light" and "small" specifications. The automatic checkweigher is made of all 304 stainless steel, which is easy to clean and maintain. The processing technology is cut and polished by imported equipment, which is smooth and beautiful, stable on the ground, and easy to install.Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

Specification Parameter

Type SG-100

Weighing Range 2-300g

Limited of product L: 100 W: 100 H: 2-150mm

Accuracy ±0.5g Depends on product

Division Scale 0.01g

Belt Speed 0- 80 m/min

Max Speed 300 pcs/min

Belt Width 100mm

Machine Weight 60kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

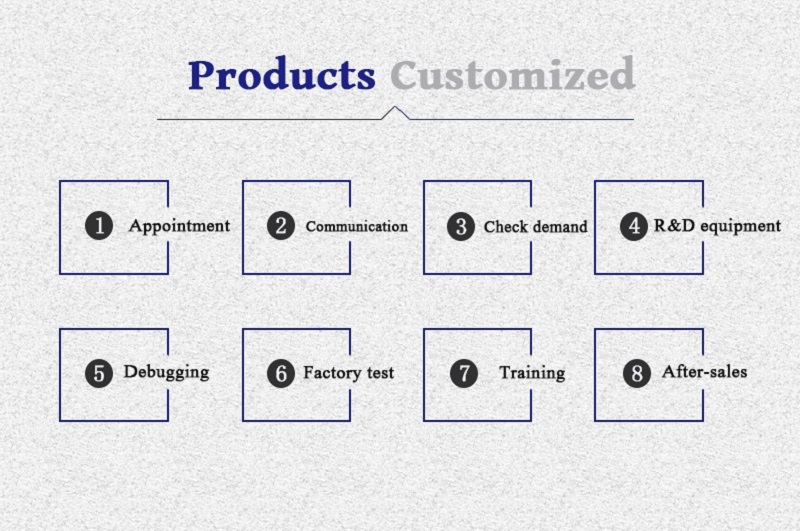

The dynamic checkweigher machine supports customization, and the specifications are for reference only. Our professional engineers will rigorously evaluate production line characteristics, specifications and environmental factors, and design the most suitable checkweigher program for the production line to meet the different needs of various complex production lines.

Main Advantages

1. The self-developed intelligent weighing signal processing algorithm realizes the non-photoelectric and photoelectric check weighing, which is suitable for different packaging objects.

2. The automatic zero tracking algorithm is adopted to maintain first-class accuracy regardless of long-term operation or environmental changes, and easily achieve high-speed and high-precision weighing

3. The main interface comprehensively displays the weighing data, production data and parameter settings of the current product.

4. The main interface has a built-in multi-language operation interface.

5. A variety of communication methods, the current checkweighing data and statistical data can be read through the RS232/RS485/Ethernet port using the MODBUS RTU/MODBUS TCP protocol, and the checkweigher can be started and stopped remotely, thereby realizing remote man-machine control and remote network control .

Application

Automatic Checkweighers should be widely used in food and beverage/pharmaceutical health care/daily chemical and light industry/raw material biology/hardware parts/aquatic products and other industries

1. Net content unqualified detection: detection of underweight/overweight of product packaging such as bags, bags, boxes, fillings, bottles, etc.;

2. Detection of missing parts in the whole box: detection of missing bags/bags/boxes/filling/bottles of whole boxes, detection of missing bags/boxes of whole bags, etc.

About Us

Shanghai Shigan Industrial Co., Ltd. is located in the beautiful scenery of Shanghai, China. It has been engaged in the production and development of assembly line packaging weighing equipment since 2010, and has obtained CE certification and a number of professional certificates. The company has always adhered to the "innovative, high-quality, and efficient" business philosophy. Provide you with perfect, high-quality products and services. Now our company's products have been sold all over the world, and have gained the trust and praise of countless customers!

Our main products are: automatic checkweighers, digital metal detectors, vertical packaging machines, premade pouch packaging machines, multi-head weighers, linear scales, and a series of assembly line packaging testing equipment.

After Sale Service

Based on the spirit of pursuing high-quality products and customer satisfaction, Shanghai Henggang Company solemnly promises you with the principles of preferential prices, considerate service, and reliable product quality.

1.Product quality commitment:

(1). The manufacturing and testing of products have quality records and testing data.

(2). For product performance testing, we sincerely invite users to personally check the whole process and performance of the product, and the product will be packaged and shipped after it is confirmed to be qualified.

2. Product price commitment:

(1). Under the same competitive conditions, our company will sincerely provide you with preferential prices on the basis of not reducing product technical performance or changing product components.

3. Delivery time commitment:

(1). Product delivery time: try to meet user requirements, if there are special requirements, which need to be completed in advance, and strive to meet user needs.

Related Products

Light Industry Air-Blown Checkweigher

Intelligent Tea Sorting Checkweigher Machine

Bag Hi-speed Checkweigher Reject Scale

Automatic Detection Weight Sorting Machine

Small Range Chewing Gum Weight Checker

Digital Metal Detection Machine

Capsule Tablet Checkweigher Machine

Food Checkweigher Manufacturer

Hot Labels:jewelry,high-precision,assembly line,checkweigher, handicraft,automatic,checkweighing,machine

This pharma bottle checkweighe...

View MoreThis metal detector + weight c...

View MoreLeveraging advanced load cell ...

View MoreThis auto checkweigher with du...

View MoreThis inline metal detector for...

View MoreThis sensitivity metal detecto...

View More