The automatic sorting checkweigher is designed for fully automatic packaging lines. When an overweight and ultra-light product is found, the conveyor belt stops and alarms, and the screen displays the weight. When the unqualified product is removed from the production line, the belt will run automatically. There are many options for the automatic ejector of the assembly line drum checkweigher.

The automatic sorting checkweigher is designed for fully automatic packaging lines. When an overweight and ultra-light product is found, the conveyor belt stops and alarms, and the screen displays the weight. When the unqualified product is removed from the production line, the belt will run automatically. There are many options for the automatic ejector of the assembly line drum checkweigher.Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

Specification Parameter

Type SG-300

Weighing Range 5-3000g/5000g

Limited of product L: 350 W:300 H: 3mm

Accuracy ±0.5-1g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 80 pcs/min

Belt Width 300mm

Machine Weight 80kg+44kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

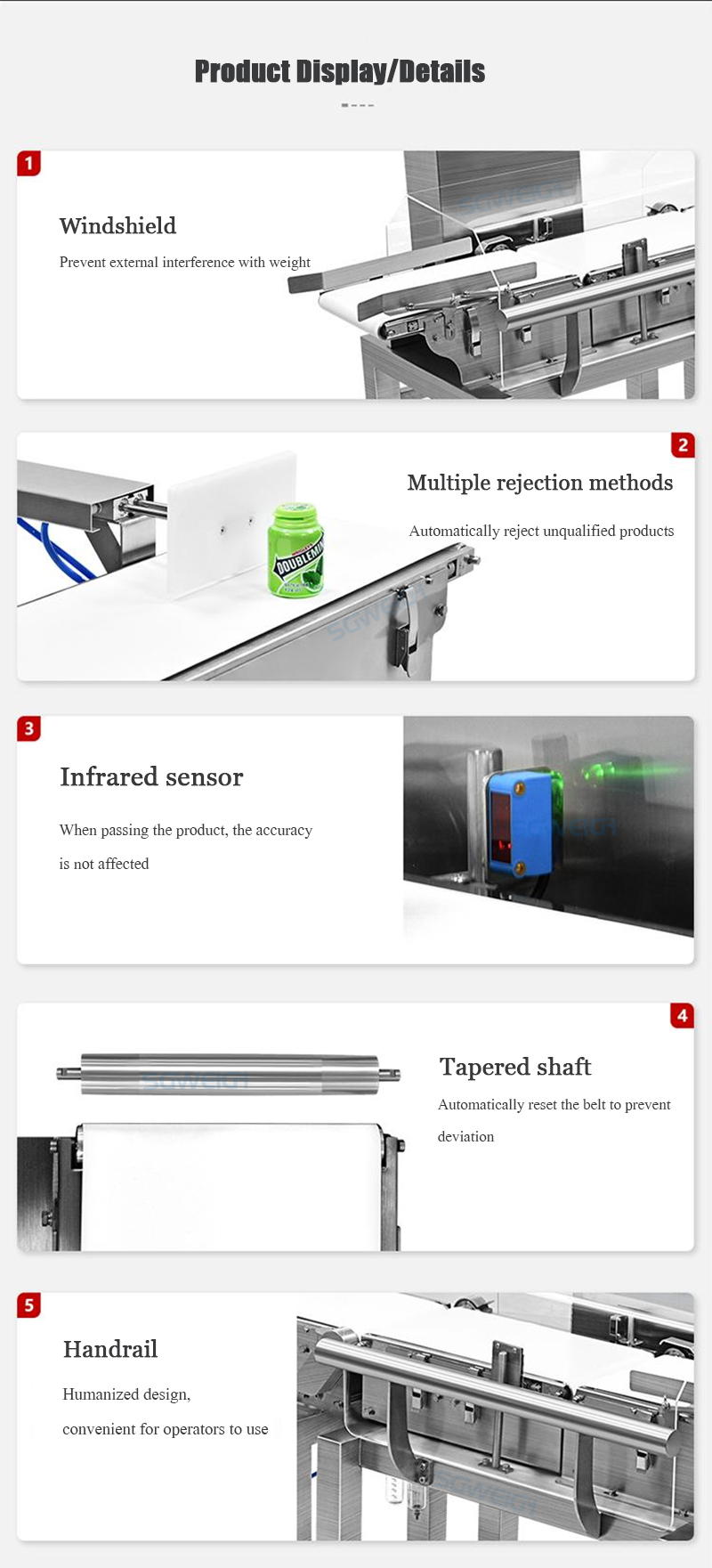

Main Advantages

1. Large-size color LCD touch screen interface, simple operation and intuitive display.

2. Support multiple languages: Chinese, English, Spanish, Italian, Japanese, Korean, etc. (customer specified), the default is Chinese and English.

3. It can store 200 kinds of product inspection data, which is convenient for users to call.

4. USB data storage interface, which can transfer report data to PC for analysis and printing.

5. Parameter setting password protection, only management personnel operation.

6. Automatic zero tracking system to ensure reliable detection data.

7. Built-in temperature and noise compensation system to ensure system stability.

8. Online printing function (customization required).

9. Data external communication interface, which can be connected to other equipment in the production line (eg: labeling machine and inkjet printer) (customization required).

10. A variety of rejection devices: lever type, air blowing type, roller push rod type, belt push rod type, drop type, flap type, belt contraction type.

11. Simple mechanical structure, easy to disassemble, clean and maintain.

Application

Online checkweigher can check whether the product is overweight/underweight, whether there are missing parts or instructions in the package, etc., and feedback information to the filling or packaging equipment. Weight sorting check weigher is widely used in the weight detection of items on the production line in the food, medicine, and chemical industries.

About Us

Shanghai Shigan Co., Ltd. was founded in 2010 and is located in Shanghai. Shanghai Shigan has an independent large-scale R&D institution, a complete manufacturing system and a huge marketing service network. It is an international assembly line packaging and testing equipment manufacturer integrating R&D, manufacturing, marketing and service. At present, our products have passed the CE EU certification and exported to Europe, the United States, Singapore, Thailand and other countries and regions. The products are widely used in food, medicine, daily chemical, chemical, agricultural and veterinary medicine industries. Over the years, the company has continuously carried out technological transformations, and the product quality has been significantly improved, which has been highly recognized by customers at home and abroad. The main products are: automatic checkweigher, digital metal detector, vertical packaging machine, premade bag packaging machine, weighing labeling machine, multi-head scale, linear scale, dividing machine, roller scale, etc.

After Sale Service

1. Service tenet: fast, decisive, accurate, thoughtful and thorough

2. Service goal: service quality wins customer satisfaction

3. Service efficiency: If the equipment fails during the warranty period or outside the warranty period, our company will arrange maintenance personnel to provide maintenance services for customers within 24 hours after receiving the notice.

4. Service principle: The product warranty period is one year. During the warranty period, our company will repair the parts damaged due to quality reasons for free. If the parts are damaged outside the warranty period, the provided accessories will only charge cost. If due to human factors If the equipment is damaged, the parts repaired or provided by our company will be calculated at the cost price.

Related Products

Safety Inspection Combo Metal Detector and Check Weigher

Commercial Granule Packing Machine Factory

15kg Stable Dynamic Check Weighing Machine

Cooked Food Conveyor Belt Metal Detector

Prevent Unqualified Products Weight Checker UK

Doypack Feed Pouch Sealing Packing Machine

Hot Labels:cashew,nut,automatic,sorting,checkweigher,equipment, food,factory,assembly line,drum,weighing machine

The carton packaged food check...

View MoreThe industrial check weigher f...

View MoreMini high accuracy checkweighe...

View MoreThe coffee beans bag checkweig...

View MoreThe core part of the high-prec...

View MoreFood package multi-level sorti...

View More