The box automatic checkweigher is a high-speed and high-precision online weighing equipment, mainly used in various automatic assembly lines and logistics conveying systems to check whether online products are overweight or underweight, and to automatically eliminate unqualified products. The dynamic check weight machine can be flexibly used in conjunction with various packaging production lines and conveying systems.

Box Tea Weight Sorting Dynamic Check Weight Machine High Speed Conveyor Belt Automatic Checkweigher

The box automatic checkweigher is a high-speed and high-precision online weighing equipment, mainly used in various automatic assembly lines and logistics conveying systems to check whether online products are overweight or underweight, and to automatically eliminate unqualified products. The dynamic check weight machine can be flexibly used in conjunction with various packaging production lines and conveying systems. Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

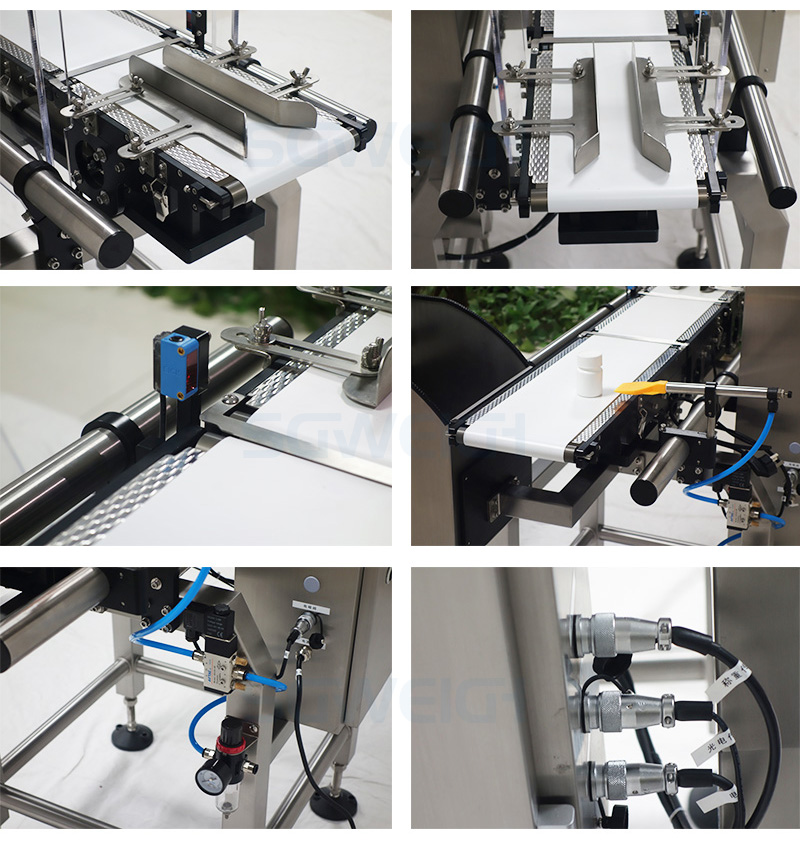

Box automatic checkweigher pictures

1. Long term use with guaranteed accuracy and no need for daily calibration

2. Automatic dynamic zero point tracking technology

3. Equipped with built-in hinge design, there are no safety dead corners, and the belt can be quickly installed and disassembled, making it easy to clean and maintain

4. Professional human-machine interface design

5. Simple user parameter settings, automatic parameter adjustment, just input product parameters and weighing requirements to complete parameter settings

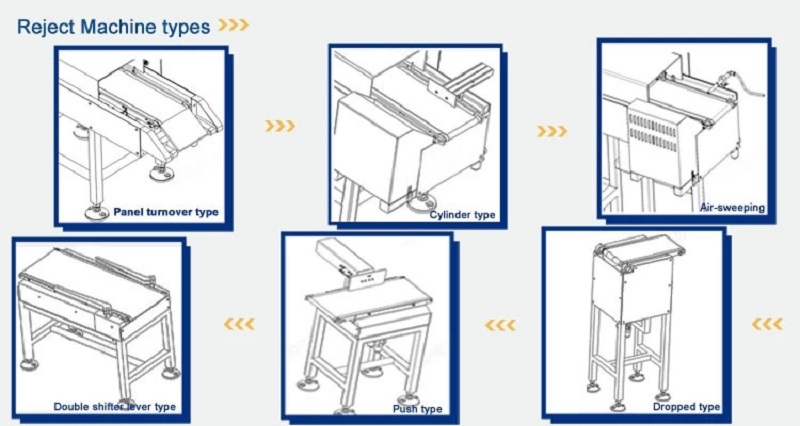

6. Accurate and efficient elimination mechanism

7. Humanized function, product database can store 1000 products

8. Password protection function ensures that unauthorized personnel cannot change data

9. Equipped with data statistics function, supporting data export, USB and Ethernet interfaces

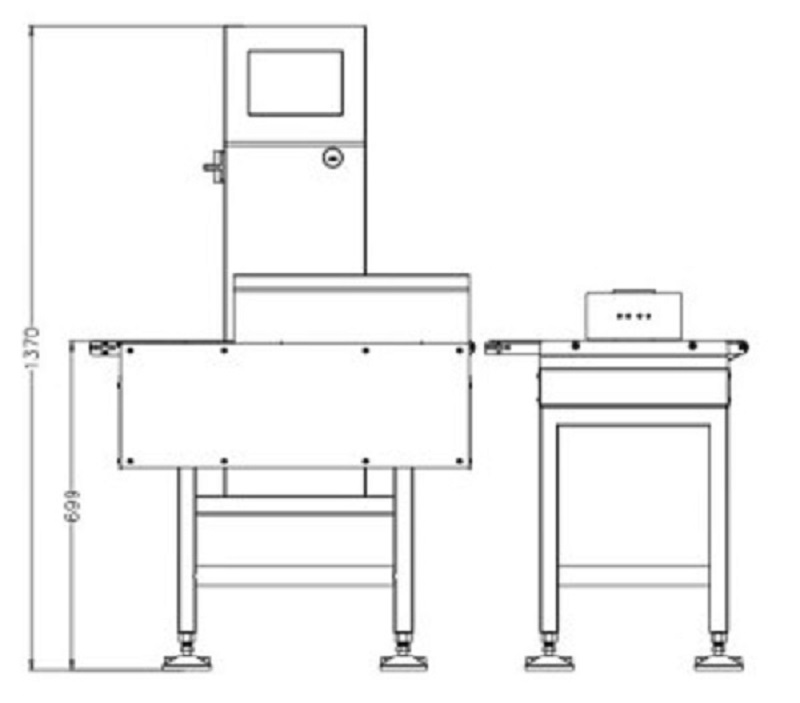

Type SG-220

Weighing Range 5-1500g

Limited of product L: 300 W:220 H: 3-200mm

Accuracy ±0.2g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 100 pcs/min

Belt Width 220mm

Machine Weight 60kg+44kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

*The above technical indicators are the detection data of the belt surface test block when the machine is empty

*The detection sensitivity may vary slightly depending on the product and usage environment

*If there are special needs, they can be customized according to customer requirements.

The automatic checkweigher is suitable for underweight and overweight detection of packaging products in various industries such as food, chemical, logistics, aviation, medicine, papermaking, building materials, batteries, etc; Detection of missing accessories within the packaging, such as instructions, accessories, gifts, desiccants, and other accessories.

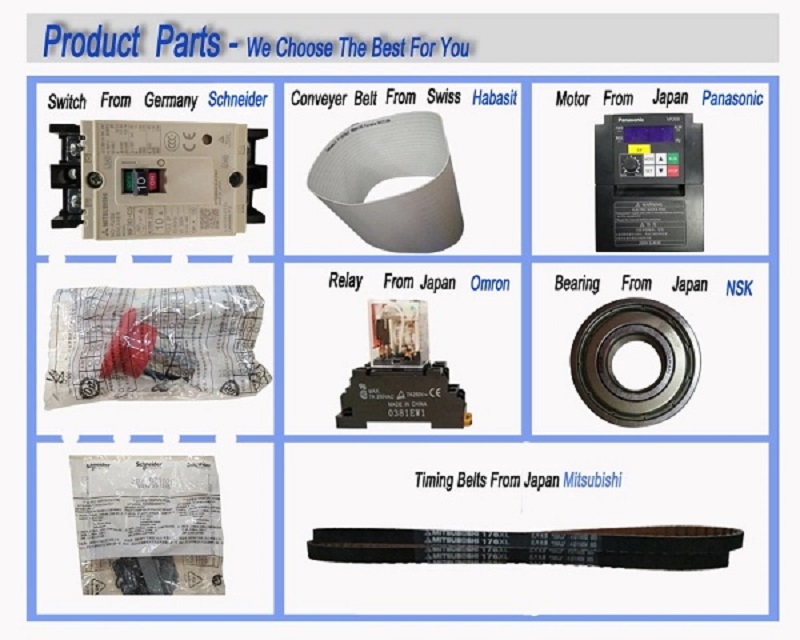

1. Competitive prices. As an original manufacturer, we have our own modern workshop processing facilities, and we can control good quality and costs ourselves.

2. Respond quickly. A well-trained professional sales team, working 24/7, responds to inquiries and questions within 24 hours.

3. Deliver on time. Ordered products are always delivered on time, which not only helps save time but also helps our customers save costs. Timely delivery enables our customers to inspect the product before proper use. We also value our punctuality and provide customers with trouble free products.

4. Integrity and professional marketing policies. We will always support you. We are committed to providing customers with the best possible service with a completely honest attitude. Specialization, fully satisfying our customers.

5. Low maintenance. The products delivered according to customer requirements not only have excellent quality, but also have low maintenance costs.

6. Storage of parts and accessories. We have sufficient parts and accessories for each machine.

7. Flexible customization of ODM capabilities and aging testing 7 * 24 hours before shipment.

-Fumigation certification for wooden packaging used for overseas shipment

-Internal plastic film wrapping protects goods from salt, wind, or damage

-Shipping terms: EXWORK, FOB, C&F, CIF sea or air freight terms

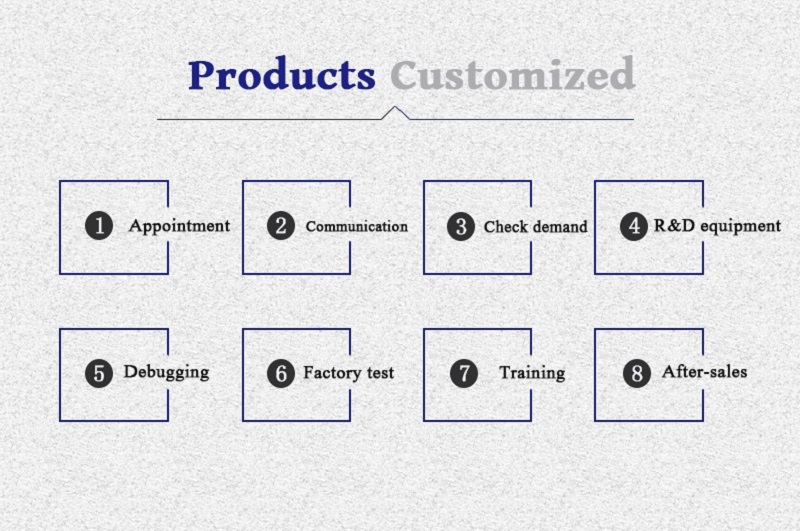

Pre sales service

1. Train customer engineers on how to use box automatic checkweighers.

2. Use product samples to test the box automatic checkweigher.

3. Machine testing videos will be sent to the customer.

After-sale service

1. Provide a manual.

2. Provide videos of installation, adjustment, setup, and maintenance.

3. Provide remote education and face-to-face online communication.

4. The warranty period of the machine is one year. If there is no human damage during the warranty period, we will replace it with a new one for you. The warranty period will be calculated from the date of B/L.PET bottle making.

Related Products

Vertical Multi Line Liquid Powder Particle Packaging Machine

Automatic Printing Paper Box Weighing Labeling Machine

Semi-automatic Single Head Liquid Filling Machine

Hardware Screw 14 head Multi Head Combined Scale

Vertical Sachet Packing Machine For Milk Powder Suger

Plastic Paper Box High Sensitivity Metal Detection Machine

Hot Labels: box,tea,weight sorting,dynamic,check weight machine,high speed,conveyor,belt,automatic,checkweigher,manufacturer,supplier,price

The dynamic logistics checkwei...

View MoreThe online checkweigher for bo...

View MoreA vertical capsules metal dete...

View MoreThe pharmaceutical capsules sa...

View MoreMulti-stage checkweigher for w...

View MoreThe high load assemble line ch...

View More