The high-speed clamping conveying checkweigher is mainly used for detecting automatic packaging production lines, which can accurately detect unqualified products on the assembly line, or group and classify the weight according to user requirements, and classify and count the products. This digital automtaic check weigher has high flexibility and can be designed with various specifications, sizes, and supporting facilities, making it widely applicable to various quantitative packaging products.

10g High-speed Blister Clamping Conveying Checkweigher Economic Digital Automtaic Check Weigher For Sale

Checkweigher as known as check weigher, check weight machine, check weighing machine, weight sorting machine, weight checker, weight sorter, and etc,.

The high-speed clamping conveying checkweigher is mainly used for detecting automatic packaging production lines, which can accurately detect unqualified products on the assembly line, or group and classify the weight according to user requirements, and classify and count the products. This digital automtaic check weigher has high flexibility and can be designed with various specifications, sizes, and supporting facilities, making it widely applicable to various quantitative packaging products. Our product specifications and sizes are rich, various styles, welcome to contact us for quotation information.

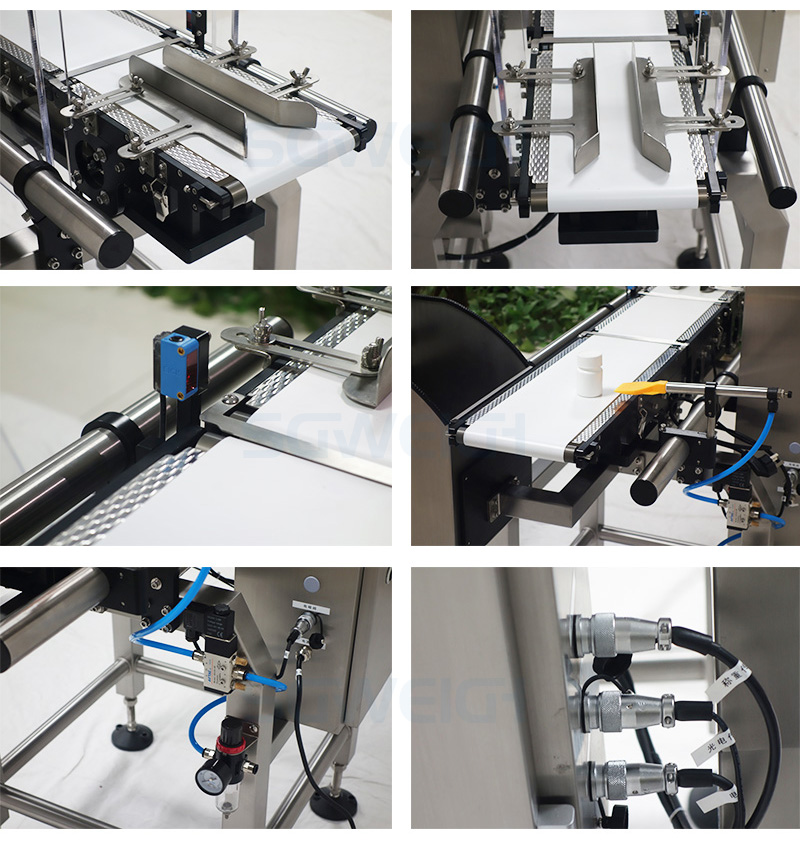

High-speed clamping conveying checkweigher pictures

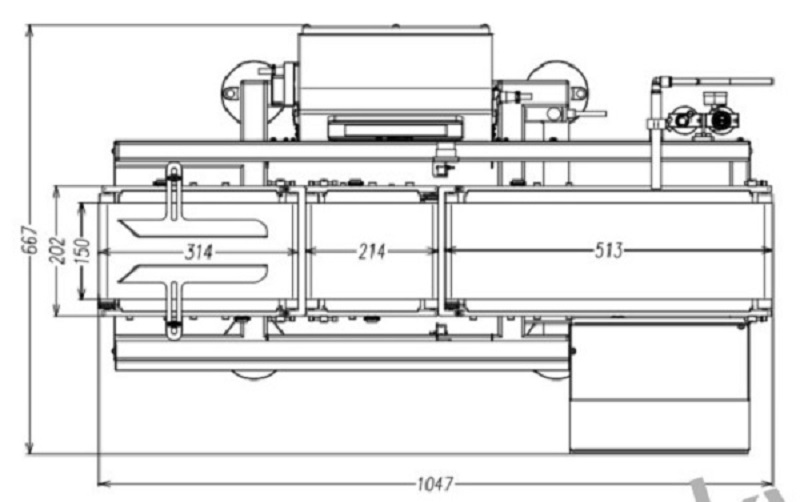

Type SG-150H

Weighing Range 3-500g

Limited of product L: 100 W:150 H: 3-150mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 90 m/min

Max Speed 160 pcs/min

Belt Width 150mm

Machine Weight 60kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

Note 1) Selection ability and accuracy. It varies depending on the actual tested product and the selected part.

Note 2) The size of the measurable product may vary depending on the specific specifications of the sorting unit. Please choose the sorting machine according to the size of the product. If the product is semi transparent or transparent, please discuss the specific situation with us.

Note: The noise of this machine is less than 70Db.

1.2000 logs, easy to find and print.

2. High precision sensors based on advanced and high-speed digital processing technology.

3. Dynamic weight compensation technology, automatic zero point analysis and tracking technology.

4.100 Product preset; Simple product editing and storage.

5. Quickly replace products and automatically adjust product sorting speed. A stainless steel conveyor designed with high waterproof grade.

6. Based on friendly touch screen operation.

7. Based on a 32-bit high-speed CPU.

8. Multifunctional operating system with multiple languages available.

9. The automatic rejection system allows for the selection of different rejection devices.

10. Updated the product learning function.

11. Various peripheral system connections and settings.

12. Alternative multiple defenses.

13. Digital signal processing technology and multiple digital filters.

1. Assembly line weighing detection: 1) overweight/underweight detection; 2) Full box missing parts detection; 3) Attachment missing detection.

2. Assembly line weighing and sorting: 1) multi-level weight sorting; 2) Sorting of non-conforming products; 3) Reject non-conforming products.

1.13 years of experience in manufacturing weighing scales.

2. Over ten years of technical team building, with a team of professional technical personnel, product design updates, and rich experience in personalized product industry needs.

3. A professional foreign trade team provides high-quality pre-sales online communication services.

4. Regularly participate in large-scale industry exhibitions in various regions and have the ability to negotiate cooperation with regional partners.

5. Our main products: automatic checkweigher, digital metal detector, automatic pakaging machine, multihead weigher, linear scale, weighing labeling machine, weighing filling machine, vacuum packing machine, checkweigher and metal detector combo, and a series of assembly line equipment.

Packaging:

Export fumigation free plywood box with quick connection design, easy to open and reuse;

The inner plastic film is wrapped to protect the goods from salt, wind, or damage;

Payment:

Online transaction guarantees orders.

We also accept wire transfer, letter of credit, and other payment methods.

Shipping:

Delivery time: 25 working days after receiving 40% deposit.

Transportation methods: sea freight, air freight, train. We also collaborate with FEDEX, DHL, UPS, and others

1) Warranty Time: 1 year, within this period we offer spare part replacement freely if there are any Non-artificial damage on them.

2) Quality: Quality of products will be strictly checked and every machine will be test to ensure it can works well before packaging.

3) Technical services: We will keep contacting with our customers all the time after selling out the machine. Please contact us without hesitation if you need any help on machines.

4) File Services: We offer instruction manual and video to teach you how to using and testing machine.

5) Accessories: We supply spare parts with competitive price after warranty time.

Related Products

Sugar Granule Multi-head Weigher Packaging Machine System

High Speed Weighing Labeling Machine for Beverage Bottle

1kg Multifunctional Granular Nuts Linear Weigher

Cheap Price Small Vertical Food Packaging Machine

Food Automatic Industrial Vacuum Packaging Machine

1-50g Powder and Grains Weighing Filling Machine

Hot Labels:10g,high-speed,blister,clamping conveying,checkweigher,economic,digital,automtaic checkweigher,check weigher,for sale,factory,supplier,manufacturer,price

The food sauce paste pipeline ...

View MoreThe dynamic logistics checkwei...

View MoreThe online checkweigher for bo...

View MoreA vertical capsules metal dete...

View MoreThe pharmaceutical capsules sa...

View MoreMulti-stage checkweigher for w...

View More