With the popularity of checkweighers, many food, seafoo […]

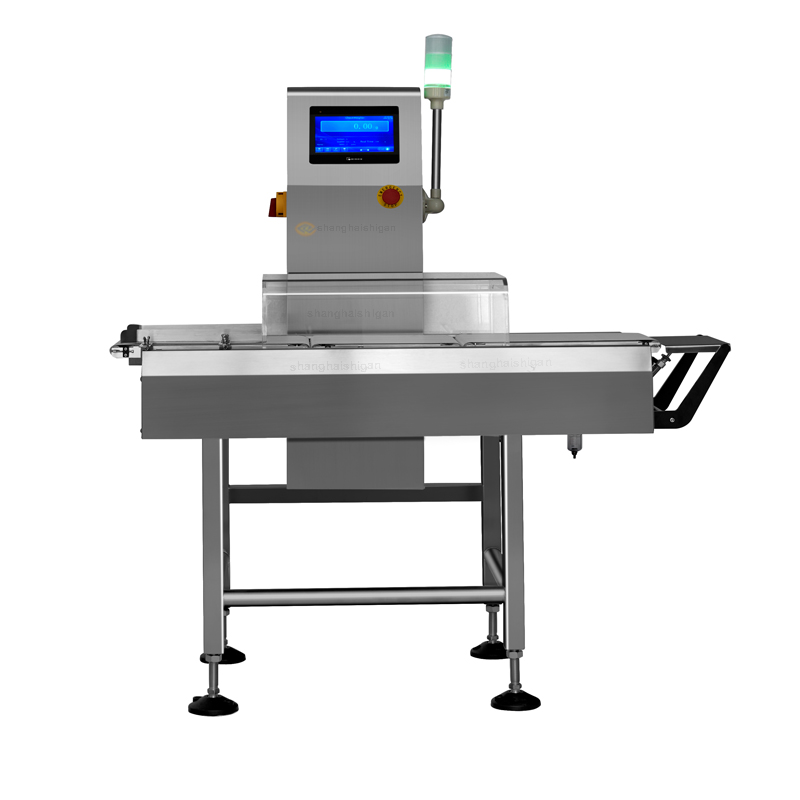

With the popularity of checkweighers, many food, seafood, and electronic products are weighed with automatic checkweigher system. The inline automatic checkweighers are designed by integrating new mechanical and electrical technologies and considering safety principles. The operators of checkweighers need to be professional Only after training can you operate the equipment. In addition to the duties of professional operators, you also need to pay attention to the operating procedures of automatic checkweigher systems.

How to standardize the operation of the automatic checkweigher system?

1. Before debugging the checkweigher module, be sure to check whether the nut on the top of the support screw of each weighing module has been loosened, and whether the sleeve is in a free state. When debugging, it is necessary to check whether the factory setting value of each parameter meets the actual needs, especially the "start-up reset" parameter, which is generally set to "start-up automatic reset" when it leaves the factory.

2. The sensor of the automatic checkweigher is a very sensitive measuring device, which must be treated with care, and should avoid vibration, extrusion or objects falling on the weighing platform (weighing conveyor belt). During transport of the checkweigher, the weighing conveyor must be held in place with screws and nuts.

3. The product enters the "acceleration section" of the quantitative checkweigher: the distance between the products will be pulled apart to ensure that when entering the "weighing section", it is a single product instead of multiple products. When the product ordering is irregular, it can also be organized by the "acceleration segment".

4. The product enters the "weighing section" of the quantitative checkweigher: the weighing system quickly detects the weight of the product; and immediately judges whether the product weight is within the target weight range. If the weight of the product is qualified, the quantitative checkweigher will be sent out without error; if the weight of the product is unqualified, a rejection delay signal will be given.

The dynamic automatic check weigher operating procedures will be shared today. Each brand of different series of checkweighers will have corresponding instruction manuals. Before using the checkweigher, the purchasing company must read it carefully and be familiar with the product buttons and functions. When the product enters the rejection section and detects the rejection delay signal, the rejection action will be made in a timely manner, and the unqualified products will be rejected accurately.If you would like to know more, please contact me!

Related Products

Small Bottle Weight Detection Scale

Highly precise ultra-fast checkweigher solutions

Prevents Underfilled or Overfilled Packages Checkweigher

Intelligent Industrial Checkweigher System

Alarm Light Check Weigher Scales With Roller

Food Weighing Labeling Machine Price

This metal detector for aluminum foil packaging medicine is a new generation of microcomputer intell...

View MoreSmall Cookie Packaging 10 Head Quantitative Multihead Weigher Shigan's modified series of digital fo...

View MoreThis high precision automatic metal detector is suitable for food, cosmetics, pharmaceutical, chemic...

View MoreMetal detectors for small metal are widely used in various processing and packaging industries such ...

View MoreGrain automatic weighing checkweigher is a device that can automatically detect whether the weight i...

View MoreThis FCL beverage weighing rejecting checkweigher equipment detects the weight of the products on th...

View More