This inline checkweigher machine adopts continuous dynamic automatic weighing method to detect the weight of items, and is equipped with an automatic rejection mechanism to realize high-speed and high-precision weight detection and sorting on the assembly line. Check weight machine is a high-speed, high-precision online weighing equipment, which can directly replace manual weighing.

This inline checkweigher machine adopts continuous dynamic automatic weighing method to detect the weight of items, and is equipped with an automatic rejection mechanism to realize high-speed and high-precision weight detection and sorting on the assembly line. Autoamtic check weight machine is a high-speed, high-precision online weighing equipment, which can directly replace manual weighing.Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

Specification Parameter

Type SG-150

Weighing Range 3-500g

Limited of product L: 200 W:150 H: 3-200mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 65 m/min

Max Speed 150 pcs/min

Belt Width 150mm

Machine Weight 60kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

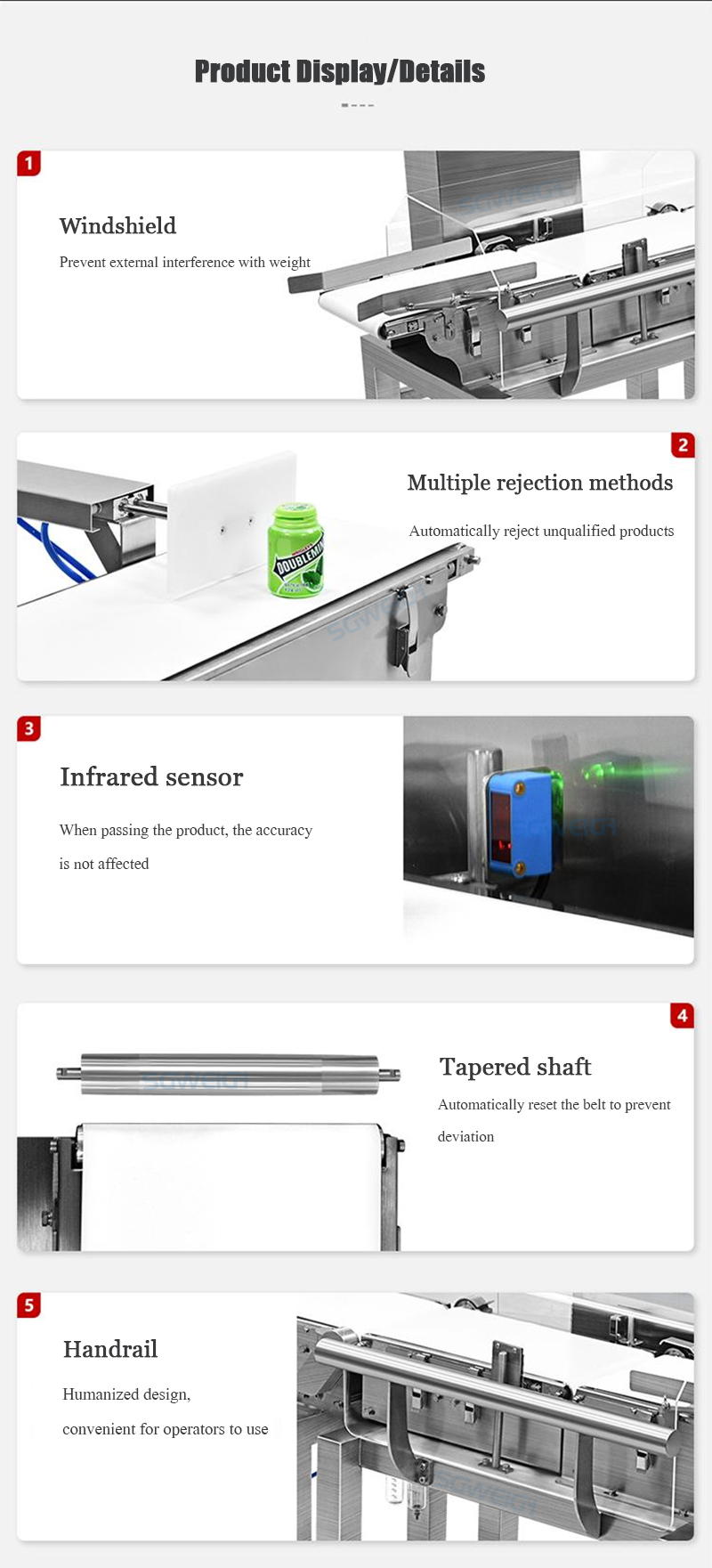

Main Advantages

Reinforced stainless steel frame, fully waterproof design

All contact parts are made of food-grade materials to ensure that the product will not be contaminated

The weight sorting machine can be customized according to the customer's specific application requirements: such as sorting grade, rejection device

Using high-precision sensors, high-speed digital signal processing technology

Dynamic weight automatic compensation technology, zero point automatic analysis and tracking technology

100 product presets, easy product editing and storage

Fast product switching and automatic adjustment of the sorting speed of corresponding products

USB mass storage, inspection records can be consulted at any time

Intuitive and easy-to-use man-machine interface, reducing operator training time and cost

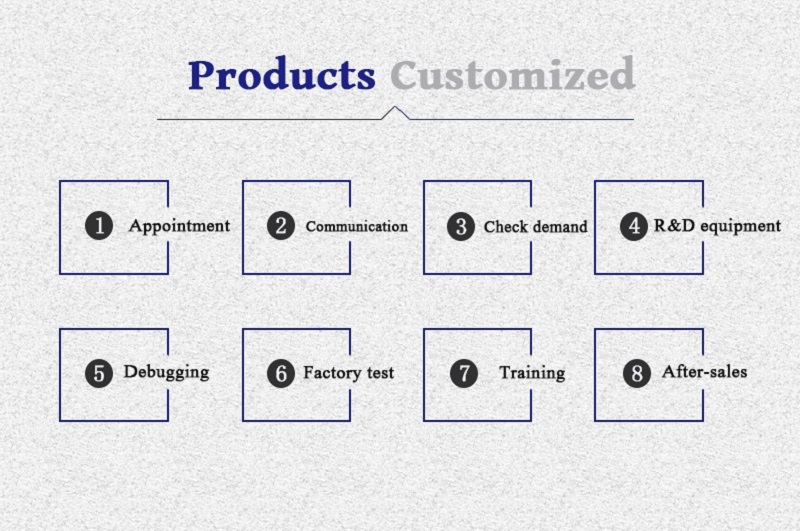

Customized

The product demonstrating may not perfectly meet your requirements,

our philosophy is to customize your real need.

To minimizing idle capacity and function. To supply you performance and cost balanced products. Following are the factors shall be taken into account during customization:

1,Products to be packed

2,Container to be filled, type and specification.

3,Capacity requirement

4,Automation requirement

5,Protection requirement

6,Other specific requirement

Application

Inline checkweigher machine is widely used in online process checkweighing applications in beverage, food, daily chemical, chemical, light industry and other industries.

About Us

Founded in 2010, Shanghai Shigan Co., Ltd. is a high-tech enterprise specializing in R&D, production and sales of testing equipment. The company has been focusing on the development and sales of automatic checkweighers, digital metal detection equipment, vertical packaging machines and other assembly line equipment for more than ten years. It has become a well-known professional equipment manufacturer and service provider in the industry. The main products are automatic checkweighers. , Digital metal detection equipment, vertical packaging machines, prefabricated bag packaging machines, linear scales, weighing labeling machines, etc. Companies attach great importance to independent research and development ability training and technical team construction, and have formed a technical team with independent research and development capabilities. , To ensure that the company can continue to introduce new products that meet customer needs.

After Sale Service

A. Pre-sale:

1. Provide real quotes for customers according to customer requirements, and timely record feedback when customers have special requirements;

2. Sign a standardized product order contract, clarify responsibilities and other related matters;

3. Provide one-year free warranty, lifetime maintenance service, and be responsible for debugging the product before shipment;

B. After sale:

1. If the customer's product fails, we will solve the problem and provide a solution for you in the first time;

2. If the customer needs on-site installation and commissioning, technical services will be arranged as soon as possible according to the customer's time and the company's situation;

3. During the warranty period, product maintenance is free, and repairs can also be provided after the warranty period. If the parts are replaced, the product parts will be provided at the cost price.

Related Products

Powder Premade Pouch Automatic Packing Machine

Heavy Weight Automatic Sorting Checkweigher

Wholesale Innovative Checkweigher Factory

Digital Automatic Electronic Weight Checker

15kg Automatic Commercial Packaging Machine

Foil Packaging Food Metal Detector

Hot Labels:wholesale,inline,checkweigher,machine,pricelist, high speed,check weight scale,supplier,Canada

The carton packaged food check...

View MoreThe industrial check weigher f...

View MoreMini high accuracy checkweighe...

View MoreThe coffee beans bag checkweig...

View MoreThe core part of the high-prec...

View MoreFood package multi-level sorti...

View More