This series of high precision digital metal detectors are based on electronic and electromagnetic technology, using stainless steel probes and frames, and a variety of protection levels for customers to choose from, adapting to various production environments. The stable metal detector can be used to detect metal contamination in raw materials and finished products.

This series of high precision digital metal detectors are based on electronic and electromagnetic technology, using stainless steel probes and frames, and a variety of protection levels for customers to choose from, adapting to various production environments. The stable metal detector can be used to detect metal contamination in raw materials and finished products.You are welcome to contact us at any time for further information.

Specification Parameter

Name: metal detector

Type : SG-8500

Main material: SUS Stainless steel (304)

Sensitivity: (Depend on the detection height)

Detection Width: 300mm 400mm 500mm

Detection Height: 100 mm 120 mm 150 mm 200 mm

Belt Height: Customized

Max Belt speed : 25m/min

Material for conveyor belt: Food grade PU belt,

Display and operation mode: LCD flat key input

Frequency: About 90 W

Powder: AC 110V/ 220V 50-60 Hz

Alarm way: Alarm, belt stop

Main Advantages

Reverse detection: using high-precision imported on-beam switch, with curve fitting algorithm, can accurately complete reverse detection

In-depth customization capability: It can be equipped with a scanning gun to meet various special requirements for in-depth customization and function development

Easy to operate and intelligent: wide LCD and wizard interface, users can easily set and operate

Reliable data: FRAM storage technology is used to ensure system parameters and data

Advanced manufacturing technology: The metal detector adopts all stainless steel probes and frames, and a variety of protection levels are available for customers to choose from, adapting to various production environments

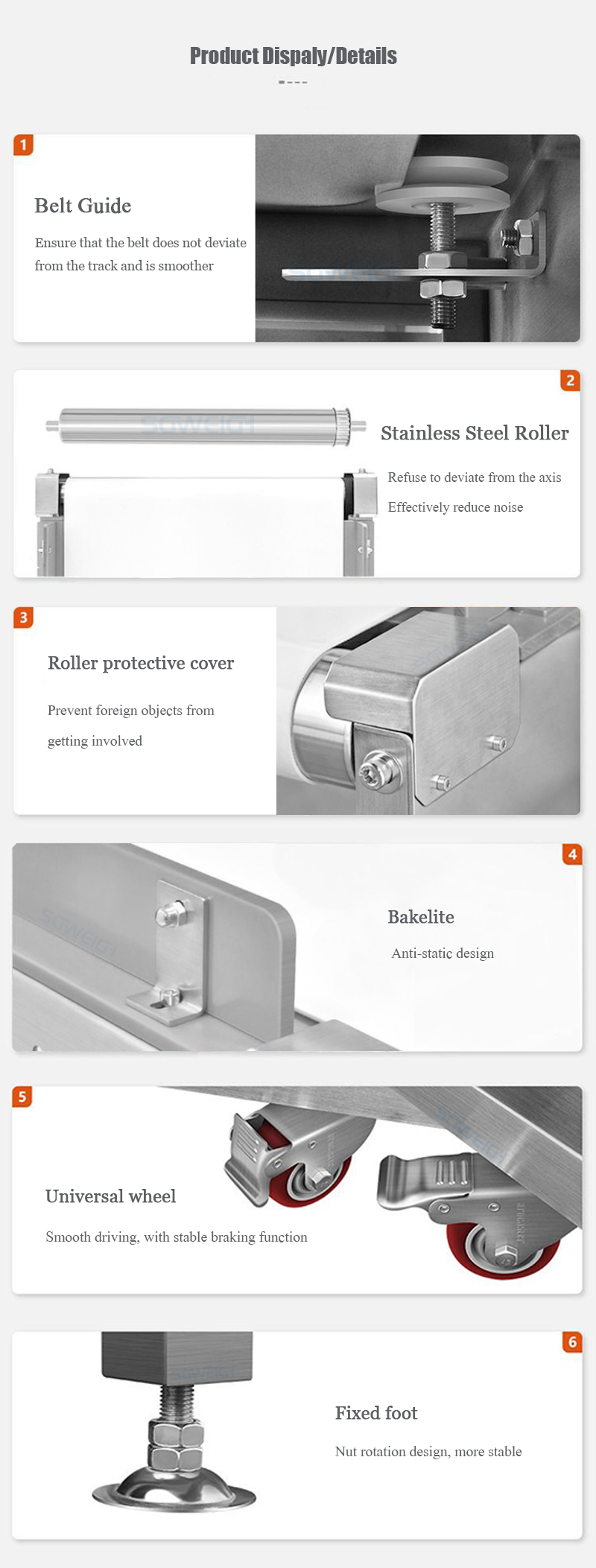

Conveyor belt deviation prevention design: The metal detector adopts a special conveyor belt deviation prevention design scheme to effectively avoid the conveyor belt deviation

Abundant peripheral interfaces: RS-485 data communication, PLC programming node, printer output can be configured, which can provide real-time data for the production management system for remote control, analysis and monitoring, and provide valuable traceability information

Rejection device: equipped with blocking arm type, air blowing type, flap type, push rod type and other rejection devices

Application

1. Detect metal impurities in products in toys, shoe materials, textiles, daily chemicals, chemicals and other industries to ensure that the products are free of metal pollution and provide reliable quality assurance.

2. Detect metal impurities in raw materials in plastics, silica gel, textile, wood, mining and other industries, protect key equipment, reduce downtime, maintenance time and costs, and improve work efficiency.

About Us

Founded in 2010, Shanghai Shigan Co., Ltd. is a high-tech enterprise specializing in R&D, production and sales of testing equipment. The company has been focusing on the development and sales of automatic checkweighers, digital metal detection equipment, vertical packaging machines and other assembly line equipment for more than ten years. It has become a well-known professional equipment manufacturer and service provider in the industry. The main products are automatic checkweigher. , Digital metal detection equipment, vertical packaging machines, premde pouch packaging machines, linear scales, weighing labeling machines, etc. Companies attach great importance to independent research and development ability training and technical team construction, and have formed a technical team with independent research and development capabilities. , To ensure that the company can continue to introduce new products that meet customer needs.

After Sale Service

1. Service tenet: fast, decisive, accurate, thoughtful and thorough

2. Service goal: service quality wins customer satisfaction

3. Service efficiency: If the equipment fails during the warranty period or outside the warranty period, our company will arrange maintenance personnel to provide maintenance services for customers within 24 hours after receiving the notice.

4. Service principle: The product warranty period is one year. During the warranty period, our company will repair the parts damaged due to quality reasons for free. If the parts are damaged outside the warranty period, the provided accessories will only charge cost. If due to human factors If the equipment is damaged, the parts repaired or provided by our company will be calculated at the cost price.

Related Products

Daily Hardware Automatic Weighing Checkweigher

Express Parcel Weighing Labeling Machine

Automatic Checkweigher For Bagged Cement

Vertical Fillet Powder Spiral Packaging Machine

Premade Pouch Packaging Machine Solutions

Rice Pellet Intelligent Combined Linear Scale

Hot Labels:silicone,digital,high-precision,metal detector, waterproof,stable,metal detection machine,manufacturer

The carton packaged food check...

View MoreThe industrial check weigher f...

View MoreMini high accuracy checkweighe...

View MoreThe coffee beans bag checkweig...

View MoreThe core part of the high-prec...

View MoreFood package multi-level sorti...

View More