A dynamic inline checkweigher is a machine for (in-line) online weighing of single packaged products. It is usually used in the middle or end of the assembly line. It performs weight detection on semi-finished products and finished products. Products that do not meet the set weight (or weight deviation) will be automatically rejected. The speed of an automatic checkweigher machine depends on the size and range of acceptable error (accuracy) of the product being weighed.

A dynamic inline checkweigher is a machine for (in-line) online weighing of single packaged products. It is usually used in the middle or end of the assembly line. It performs weight detection on semi-finished products and finished products. Products that do not meet the set weight (or weight deviation) will be automatically rejected. The speed of an automatic checkweigher machine depends on the size and range of acceptable error (accuracy) of the product being weighed. The dynamic checkweigher can also be attached with additional detection devices, such as metal detectors and X-ray machines, which can simultaneously realize multiple property detections to eliminate defective products and ensure product quality multiple times.Our product specifications and sizes are rich, various styles, welcome to contact us for quotation information.

Dynamic inline checkweigher picturs

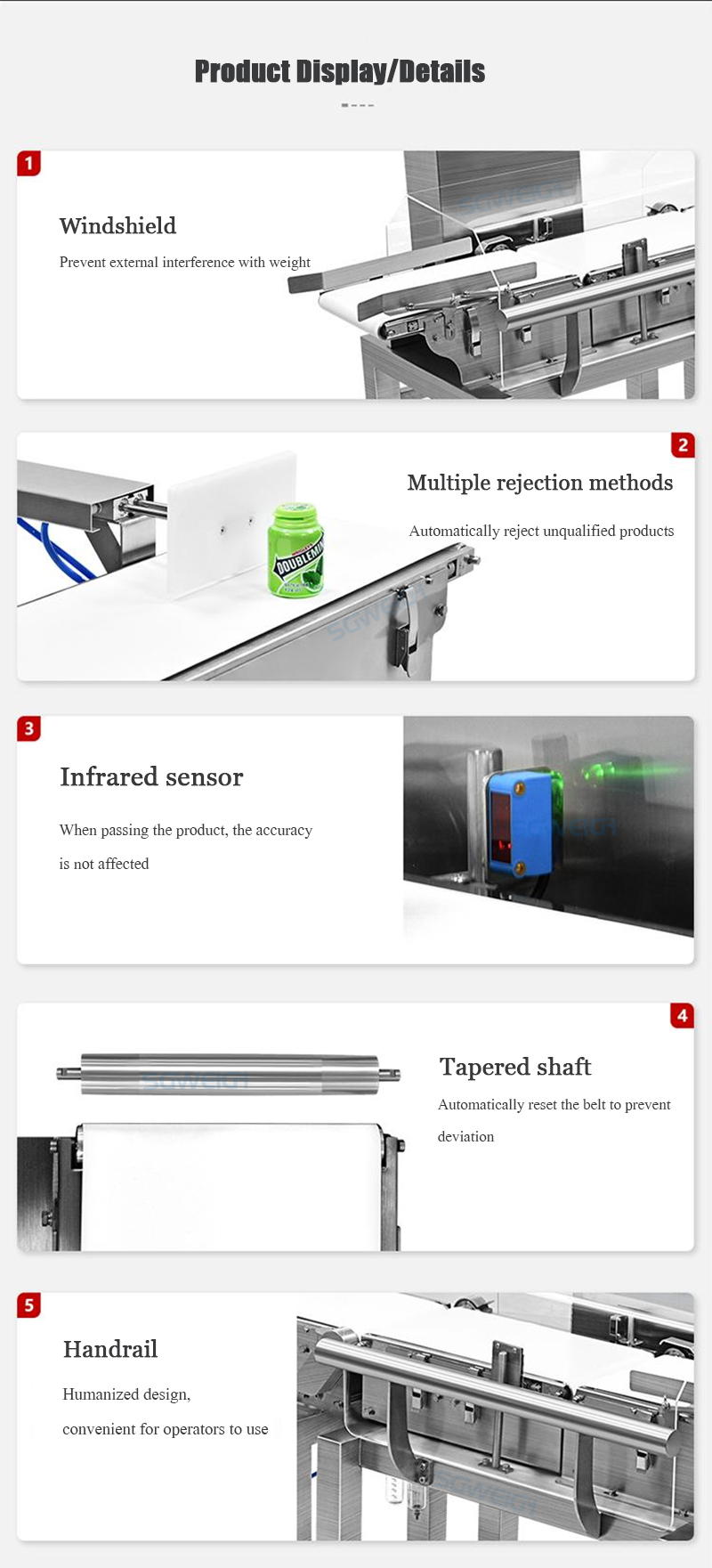

1. High-precision digital load cell system

2. High-speed digital filter processing and auto-zero function

3. Unique dynamic weighing anti-interference technology.

4. Humanized operating system, easy to learn and operate, available in multiple languages

5. Data storage and output printing functions.

6. All stainless steel and waterproof structure.

7. Types of exclusion/sorting: push rod, lever/bezel, air jet, slide rail are available.

8. After 10 years of actual market application verification, the quality is reliable and stable.

9. Service with technical engineers available overseas

The dynamic inline checkweigher is widely used in health care products, bread, precious metals, instant noodles, chocolate, packaged food, daily necessities, Chinese herbal medicines, chewing gum and other bagged products. out. The weighing and checking machine has the characteristics of high precision and fast checking speed, which greatly saves the cost of product quality control of enterprises.

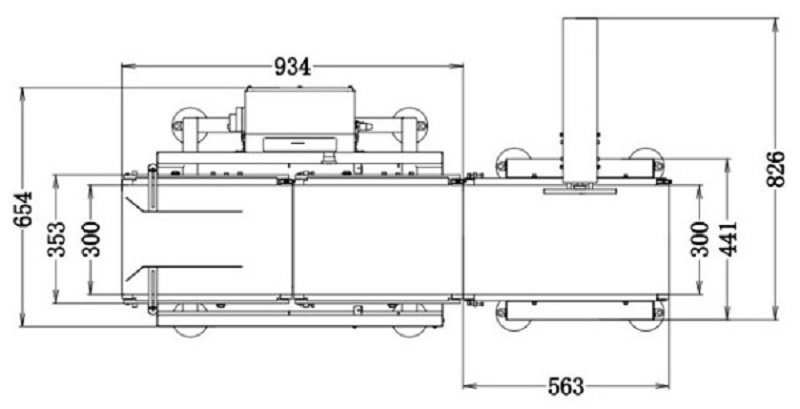

Type SG-300

Weighing Range 5-3000g/5000g

Limited of product L: 350 W:300 H: 3mm

Accuracy ±0.5-1g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 80 pcs/min

Belt Width 300mm

Machine Weight 80kg+44kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

1st step: Customer has showed his special requirements.

2nd step: We try to understand the conception and pattern from customer with simple draft or refer picture.

3rd step: Making the conceptive CAD drawing based on communication and understanding.

4th step: Making the detail and 3D drawing agter fixed the design and other details.

5th step: Offer the quotation after confirm the design,material and surface treament.

6th step: Making the sample for approval.

7th step: Testing installation after demo mock up.

8th step: Big production delivery and service after sales.

The machine will be fixed and then packed in wooden cases.

Fast Delivery! The earliest delivery is 15 days after payment.

1. Service tenet: fast, decisive, accurate, thoughtful and thorough

2. Service goal: service quality to win customer satisfaction

3. Service efficiency: If the equipment fails within the warranty period or outside the warranty period, our company will arrange maintenance personnel to perform maintenance services for customers within 24 hours after receiving the notice.

4. Service principle: The product warranty period is one year. During the warranty period, our company will repair the parts damaged due to quality reasons for free. If the parts are damaged outside the warranty period, only the cost will be charged for the accessories provided. If it is due to human factors For equipment damage caused, our company repairs or provides accessories at cost price.

Related Products

Intelligent Industrial Checkweigher System

Alarm Light Check Weigher Scales With Roller

Gummy Candy Multihead Weigher Manufacturer

1kg small semi automatic Weighing Filling Machine

in line check weigher system checkweigher pharmaceutical

Food Weighing Labeling Machine Price

Hot Labels:inline checkweigher,manufacturers,price,prevents underfilled or overfilled packages,automatci check weigher,check weight machine,China

The carton packaged food check...

View MoreThe industrial check weigher f...

View MoreMini high accuracy checkweighe...

View MoreThe coffee beans bag checkweig...

View MoreThe core part of the high-prec...

View MoreFood package multi-level sorti...

View More