The industrial measurement automatic checkweigher adopts a large-size color touch screen interface, which is simple to operate and intuitive to display. Powerful data statistics function, record daily inspection data, can store 100 sets of product data, which can be called by customers at any time, and the data will not be lost if sudden power failure; Shanghai Shigan produces dynamic check weight machine according to different products and different environmental requirements Customize various applicable solutions.

The industrial measurement automatic checkweigher adopts a large-size color touch screen interface, which is simple to operate and intuitive to display. Powerful data statistics function, record daily inspection data, can store 100 sets of product data, which can be called by customers at any time, and the data will not be lost if sudden power failure; Shanghai Shigan produces dynamic check weight machine according to different products and different environmental requirements Customize various applicable solutions.

If there are any problems afterward,please feel free to contact us.

Specification Parameter

Type SG-450

Weighing Range 0.05-20/30kg

Limited of product L: 500 W:450 H: 3-400mm

Accuracy ±1g

Division Scale 0.1g

Belt Speed 0- 40 m/min

Max Speed 40 pcs/min

Belt Width 450mm

Machine Weight 100kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

Main Advantages

1. Large-size color LCD touch screen interface, simple operation and intuitive display.

2. The automatic checkweigher supports multiple languages: Chinese, English, Spanish, Italian, Japanese, Korean, etc. (specified by the customer), and the default is Chinese and English.

3. The digital check weigher can store 200 kinds of product inspection data, which is convenient for users to call.

4. USB data storage interface, which can transfer report data to PC for analysis and printing.

5. Parameter setting password protection, only management personnel operation.

6. Automatic zero tracking system to ensure reliable detection data.

7. The built-in temperature and noise compensation system of the conveyor belt checkweigher ensures the stability of the system. Online printing function (customization required).

8. The weight sorting checkweigher has a data external communication interface, which can be connected to other equipment in the production line (eg: labeling machine and inkjet printer) (customization required).

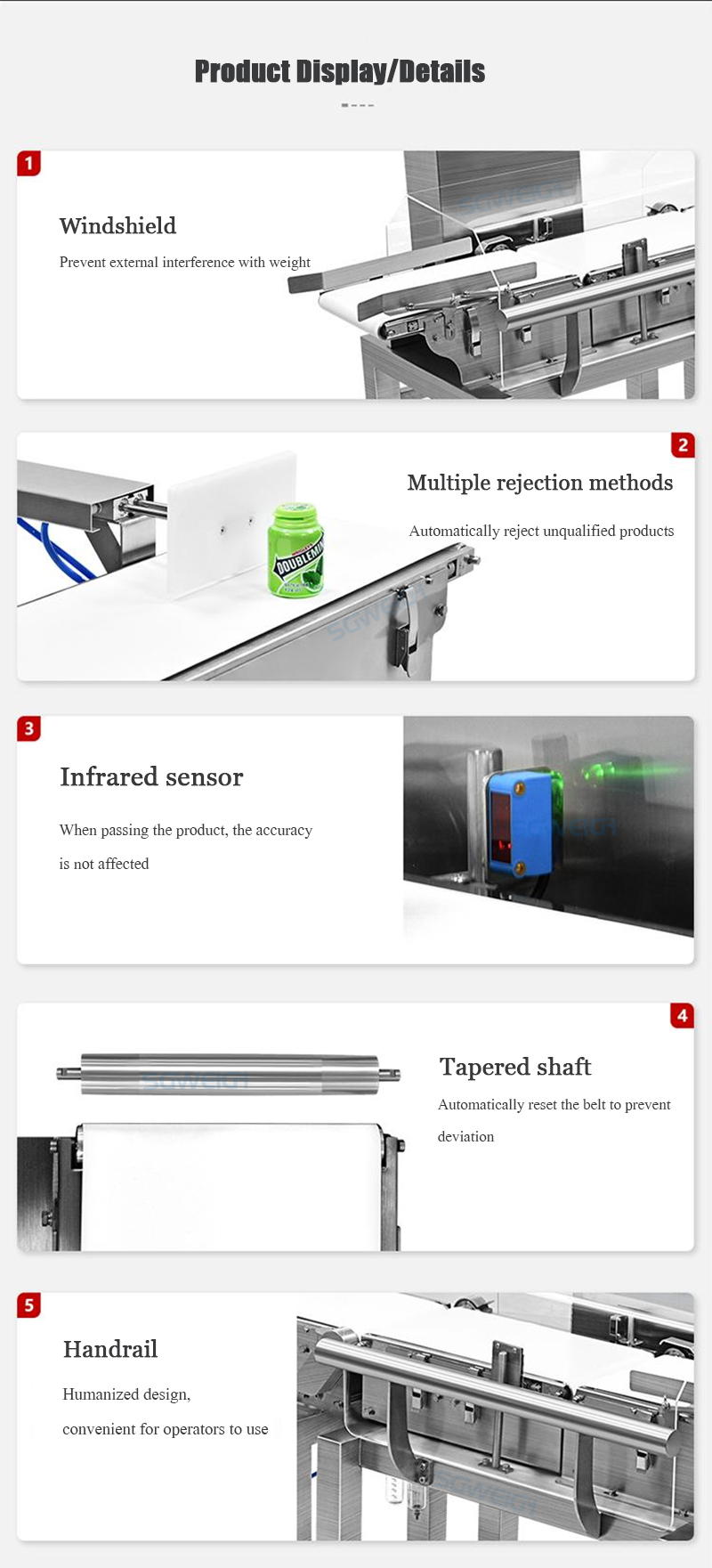

9. Multiple rejection devices: push rod rejection, fall rejection. (Customer required).

10. The mechanical structure of the dynamic checkweigher is simple, which is convenient for disassembly, cleaning and maintenance.

Work process of online checkweigher machine

The main function of the automatic online checkweigher is to automatically sort out the defective products outside the set weighing error range. Qualified products flow into the qualified product area; unqualified products automatically flow into the unqualified product area.

1. The product is transported in through the previous section of the assembly line or manually put into the "acceleration section" by hand.

2. The product enters the "acceleration section" of the weight tester: the distance between the products will be stretched to ensure that it is a single product instead of multiple products when entering the "weighing section". When the products are arranged irregularly, they can also be sorted by "accelerated segment".

3. The product enters the "weighing section" of the weight detector: the weighing system quickly detects the weight of the product; and immediately determines whether the product weight is within the target weight range. At the same time, the weight value of the product will be displayed on the screen. If the product weight is qualified, it will be sent out of the weighing machine without error; if the product weight is unqualified, it will give a rejection delay signal. At the same time, the system will automatically record the number of qualified and unqualified products.

4. The product enters the "reject section" of the weight tester: when the rejection section detects the rejection delay signal, it will take the rejection action in a timely manner to accurately reject the unqualified products.

Application

Automatic check weight machine is mainly used for automatic weight detection, upper and lower limit discrimination or weight classification selection on various automated assembly lines and logistics conveying systems. It is widely used in online detection in the pharmaceutical, food, toy, hardware, chemical and other industries. In addition, it can directly replace manual weighing to improve production efficiency, consistency and reliability of weighing.

About Us

Shanghai Shigan Co., Ltd. was founded in 2010 and is located in Shanghai. Shanghai Shigan has an independent large-scale R&D institution, a complete manufacturing system and a huge marketing service network. It is an international assembly line packaging and testing equipment manufacturer integrating R&D, manufacturing, marketing and service. At present, our products have passed the CE EU certification and exported to Europe, the United States, Singapore, Thailand and other countries and regions. The products are widely used in food, medicine, daily chemical, chemical, agricultural and veterinary medicine industries. Over the years, the company has continuously carried out technological transformations, and the product quality has been significantly improved, which has been highly recognized by customers at home and abroad. The main products are: automatic checkweigher, digital metal detector, vertical packaging machine, premade bag packaging machine, weighing labeling machine, multi-head scale, linear scale, dividing machine, roller scale, etc.

After Sale Service

For many years, Shanghai Shigan has been serving customers in various industries. After research and exploration, a complete product service guarantee system has been summed up to provide users with high-quality and timely pre-sales, sales and after-sales services:

1. Quality Assurance

Shigan guarantees that the electronic scales provided to customers are produced by the original factory, and the factory materials and accessories are complete. In order to maintain the normal operation and maintenance of the contract equipment, our company guarantees that the technical products provided are complete, clear and correct.

2. Quality assurance measures

Warranty period: Provide on-site service during the warranty period.

(1). The company has an after-sales service center, which is mainly responsible for after-sales service and technical consultation. Ensure that there are engineers to provide various technical services at any time.

(2). There are remote services on the Internet to solve various problems in a timely manner and provide technical services 24 hours a day.

Vulnerable accessories: The company reserves stocks of various commonly used accessories to ensure that the problem can be solved in a short time.

Related Products

Pharmaceutical Production Line Checkweigher

Automatic Metal Detector For Bagged Drugs

Bottle Cap Sorting Checkweigher Equipment Manufacturer

Hardware Magnet High-Speed Dynamic Checkweigher

Single-Head Quantitative Weighing Equipment

Conveyor Belt Metal Detection Machine For Sale

Hot Labels:industrial,measurement,automatic,checkweigher, dynamic,check weight machine,wholesale ,purchase

The carton packaged food check...

View MoreThe industrial check weigher f...

View MoreMini high accuracy checkweighe...

View MoreThe coffee beans bag checkweig...

View MoreThe core part of the high-prec...

View MoreFood package multi-level sorti...

View More