With fast and accurate weight collection and easy integration of existing transmission equipment, this dynamic automatic checkweigher can help users to check various weight abnormalities and identify corresponding quality abnormalities. Conveyor belt checkweighers provide professional customized solutions according to the user's product characteristics and application scenarios.

In line Check Weigher Conveyor Belt Checkweigher Conveyor Weight Checking Machine With Rejector

With fast and accurate weight collection and easy integration of existing transmission equipment, this dynamic automatic checkweigher can help users to check various weight abnormalities and identify corresponding quality abnormalities. Conveyor belt checkweighers provide professional customized solutions according to the user's product characteristics and application scenarios.Our product specifications and sizes are rich, various styles, welcome to contact us for quotation information.

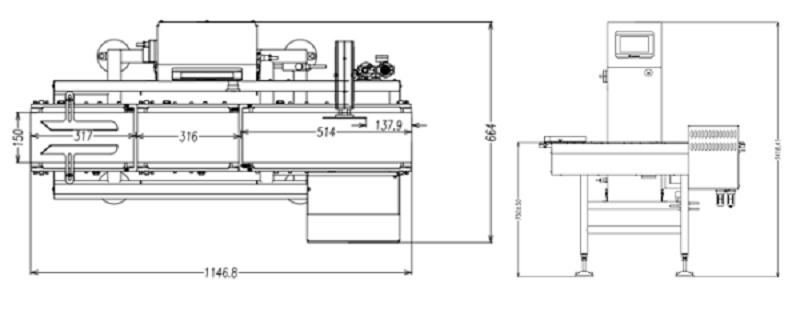

Dynamic automatic checkweigher pictures

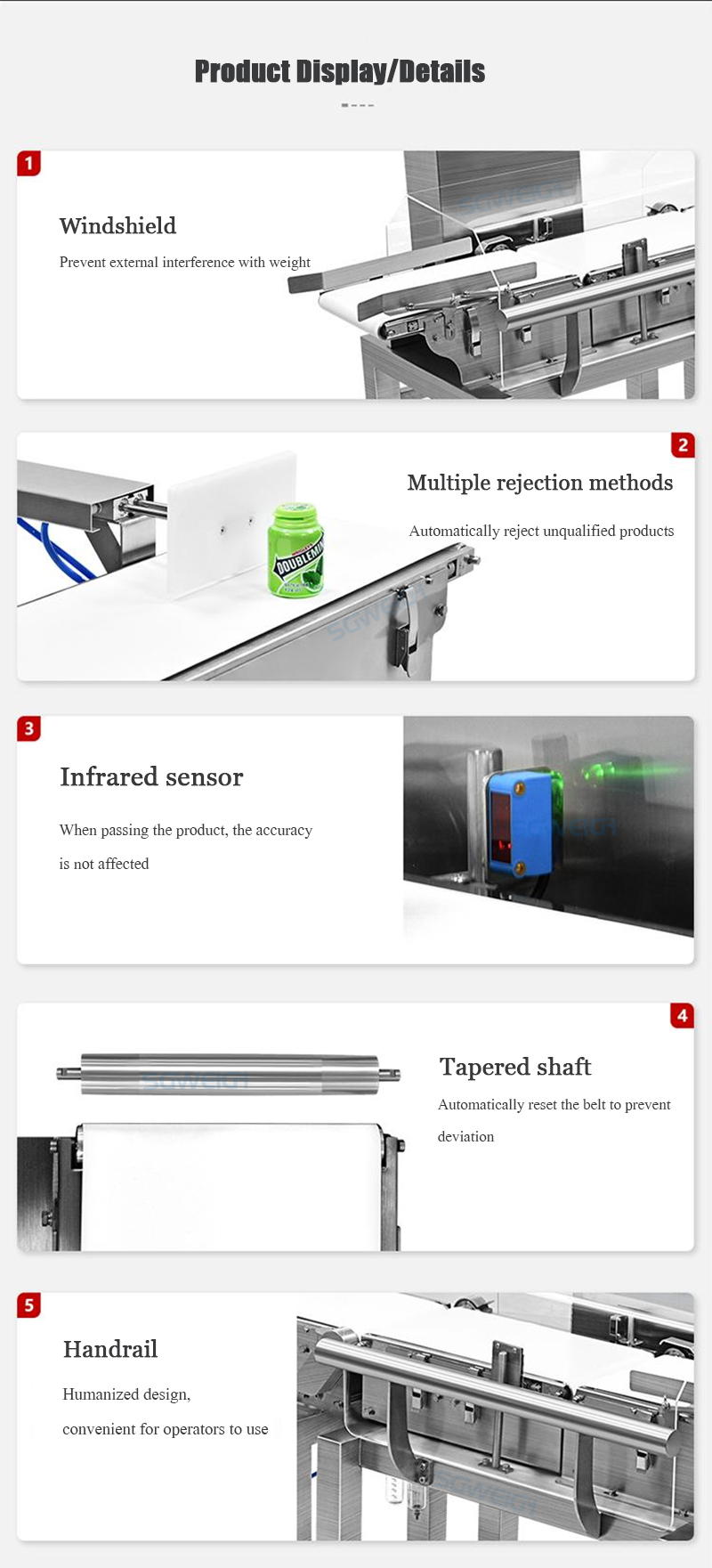

1) Special design and matching can ensure long-term operation stability;

2) A single sensor and a single sensor are not limited by the area of the weighing platform, and can achieve high-speed and high-precision detection requirements;

3) The installed communication module can upload data in real time and monitor it effectively;

4) The huge range is convenient for the detection of large and small objects in the logistics industry;

5) 7-inch or 10-inch color high-definition touch screen, the information is clear at a glance;

6) Professional operating system with rich functions and simple operation.

Specification parameter

Type SG-150

Weighing Range 3-500g

Limited of product L: 200 W:150 H: 3-200mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 65 m/min

Max Speed 150 pcs/min

Belt Width 150mm

Machine Weight 60kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

1st step: Customer has showed his special requirements.

2nd step: We try to understand the conception and pattern from customer with simple draft or refer picture.

3rd step: Making the conceptive CAD drawing based on communication and understanding.

4th step: Making the detail and 3D drawing agter fixed the design and other details.

5th step: Offer the quotation after confirm the design,material and surface treament.

6th step: Making the sample for approval.

7th step: Testing installation after demo mock up.

8th step: Big production delivery and service after sales.

1. Application of dynamic checkweigher in electronics and toy industry: parts missing parts detection (such as toy missing parts detection, screw package missing parts detection, TV sets and set-top boxes and other products lacking parts detection);

2. The application of dynamic checkweigher in the daily chemical product industry: detection of missing parts of cosmetics, whether the whole bag of laundry is missing, and whether the whole box of toothbrushes is missing;

3. Application of dynamic checkweigher in hardware and other industries: detection of missing parts of stainless steel tableware and knives;

4. The application of dynamic checkweigher in the pharmaceutical industry: detection of missing drug bags, whether the whole box of drugs lacks instructions, and whether the net content of drugs is qualified;

5. The application of dynamic checkweigher in the food industry: the detection of the lack of material packages of instant noodles and other convenience foods, whether the whole box of biscuits is lacking in quantity.

In the spirit of pursuing high-quality products and customer satisfaction, Shanghai Henggang Company solemnly promises you the principle of preferential price, thoughtful service and reliable product quality.

1. Product quality commitment:

(1). There are quality records and testing data for the manufacture and testing of products.

(2). For the inspection of product performance, we sincerely invite users to inspect the whole process and performance of the product in person. After the product is confirmed to be qualified, it will be packaged and shipped.

2. the product price commitment:

(1). Under the same competitive conditions, our company will sincerely provide you with a preferential price on the basis of not reducing the technical performance of the product or changing the product components.

3. Delivery time commitment:

(1). Product delivery time: as far as possible according to user requirements, if there are special requirements, it needs to be completed in advance, and strive to meet user needs.

Related Products

High-Speed Manual Inspection Checkweigher Stable

Power Roller Checkweigher With Alarm Light

Weight Checking Machine With Rejection Device

Platform Semi-Automatic Roller Checkweigher

Automatic Boxed Checkweigher Price Belt Sorter

1-100g Semi-Auto Weighing Filling Machine

Hot Labels:inline,check weigher,conveyor,belt,checkweigher conveyor,weight checking machine,rejector,manufacturer,dynamic checkweigher,price

The online checkweigher for bo...

View MoreA vertical capsules metal dete...

View MoreThe pharmaceutical capsules sa...

View MoreMulti-stage checkweigher for w...

View MoreThe high load assemble line ch...

View MoreThe online soft hard capsule c...

View More