The high accuracy checkweigher inspection is based on dynamic weighing technology, which realizes automatic transportation of products in motion to the weighing platform for automatic weighing and classification, and automatic rejection of unqualified products. The automatic check weigher has the advantages of high precision, full automation, simple and convenient operation, etc.

The high accuracy checkweigher inspection is based on dynamic weighing technology, which realizes automatic transportation of products in motion to the weighing platform for automatic weighing and classification, and automatic rejection of unqualified products. The automatic check weigher has the advantages of high precision, full automation, simple and convenient operation, etc.For further information about our machines, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

Specification Parameter

Type SG-300

Weighing Range 5-3000g/5000g

Limited of product L: 350 W:300 H: 3mm

Accuracy ±0.5-1g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 80 pcs/min

Belt Width 300mm

Machine Weight 80kg+44kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

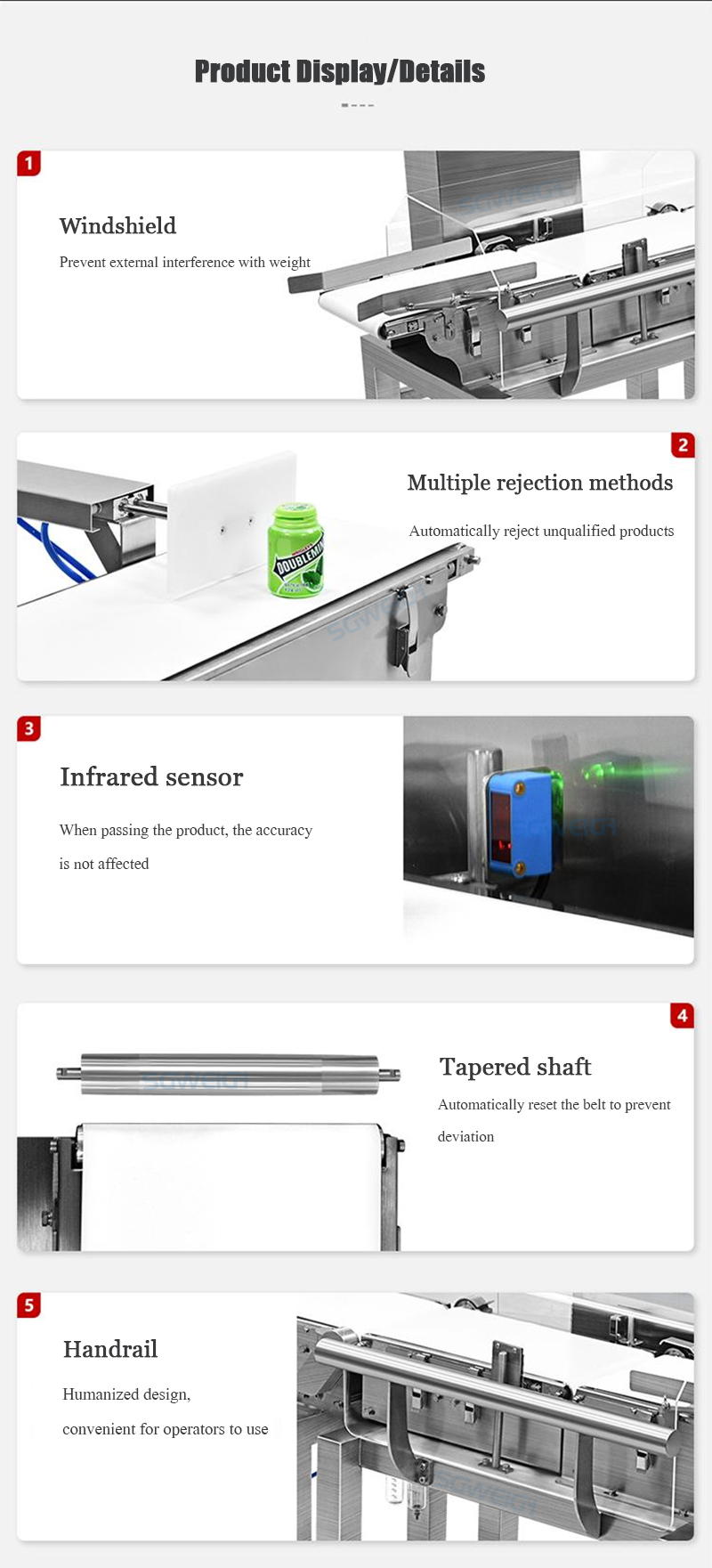

Main Advantages

1.The packaged products are weighed and tested by the high accuracy checkweigher, the qualified ones are returned to the original conveyor belt, and the unqualified ones are rejected (or alarmed and stopped), and it has the functions of classifying and counting the products according to the settings.

2.Standard 3 weight classification areas, directly displayed on the screen

3.Can store 10 kinds of product data, easy to switch products

4.Weight classification and statistics, fault alarm information

5.Dust-proof display terminal, menu operating system

6.Two to three-section conveyor structure, effectively guaranteeing accuracy

7.Conveyor is easy to disassemble and assemble, easy to repair and maintain

8.Conveyor speed is adjustable to meet site requirements

9.Carbon steel structure support, surface spray treatment

10Various expansion equipment can be installed according to customer needs

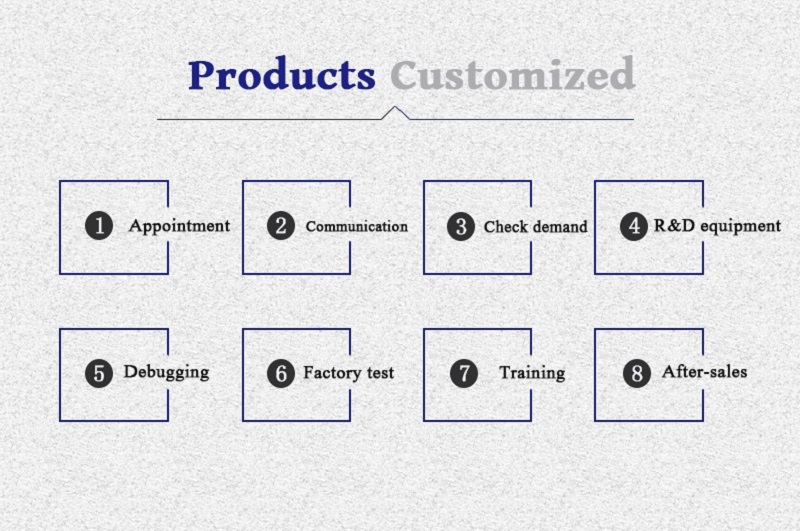

Customized

The product demonstrating may not perfectly meet your requirements,

our philosophy is to customize your real need.

To minimizing idle capacity and function. To supply you performance and cost balanced products. Following are the factors shall be taken into account during customization:

1,Products to be packed

2,Container to be filled, type and specification.

3,Capacity requirement

4,Automation requirement

5,Protection requirement

6,Other specific requirement

Using Range

The conveyor belt checkweigher for packaging products is mainly suitable for various food, pharmaceuticals, chemicals, beverages, plastics, cosmetics, rubber, etc.

Our Company

Shanghai Shigan Industrial Co., Ltd. is located in the beautiful scenery of Shanghai, China. It has been engaged in the production and development of assembly line packaging weighing equipment since 2010, and has obtained CE certification and a number of professional certificates. The company has always adhered to the "innovative, high-quality, and efficient" business philosophy. Provide you with perfect, high-quality products and services. Now our company's products have been sold all over the world, and have gained the trust and praise of countless customers!

Our main products are: automatic checkweighers, digital metal detectors, vertical packaging machines, premade pouch packaging machines, multi-head weighers, linear scales, and a series of assembly line packaging testing equipment

After Sale Service

1. Service tenet: fast, decisive, accurate, thoughtful and thorough

2. Service goal: service quality wins customer satisfaction

3. Service efficiency: If the equipment fails during the warranty period or outside the warranty period, our company will arrange maintenance personnel to provide maintenance services for customers within 24 hours after receiving the notice.

4. Service principle: The product warranty period is one year. During the warranty period, our company will repair the parts damaged due to quality reasons free of charge. If the parts are damaged outside the warranty period, the provided accessories will only charge the cost. If due to human factors If the equipment is damaged, the parts repaired or provided by our company are calculated at the cost price.

Related Products

Inline Production Line Checkweigher Supplier

Automatic Checkweigher and Labeling Machine Combo

Industrial Metal Detection Machine With Touch Screen

Different Weight Sorting Inline Check Weigher

Small Liquid Water Checkweigher For Bottles

Granule Automatic Packing Machine Price

Hot Labels:commercial,batteries,automatic,check weigher, high accuracy,checkweigher,inspection,solution

The carton packaged food check...

View MoreThe industrial check weigher f...

View MoreMini high accuracy checkweighe...

View MoreThe coffee beans bag checkweig...

View MoreThe core part of the high-prec...

View MoreFood package multi-level sorti...

View More