This assembly line belt checkweigher is used in the front, middle, and back ends of the assembly line to perform high-speed automated weighing, counting, classification, etc. of products passing through the line, and can preset the product weight to exceed the preset weight of the product, trigger the alarm when the lower limit.

Carton Assembly Line Belt Checkweigher, Quantitative Check Weigher Alarm Checkweigher

Assemble line checkweigher as known as automatic check weigher, inline check weighing machine, dynamic check weight machine,

This assembly line belt checkweigher is used in the front, middle, and back ends of the assembly line to perform high-speed automated weighing, counting, classification, etc. of products passing through the line, and can preset the product weight to exceed the preset weight of the product, trigger the alarm when the lower limit. Quantitative check weigher can achieve the purpose of saving manpower and improving efficiency, and avoid unnecessary loss due to excessive packaging or customer complaints due to insufficient weight. It is the best quality inspection equipment for automatic production lines and packaging lines.For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

Specification parameter

Type SG-450

Weighing Range 0.05-20/30kg

Limited of product L: 500 W:450 H: 3-400mm

Accuracy ±1g

Division Scale 0.1g

Belt Speed 0- 40 m/min

Max Speed 40 pcs/min

Belt Width 450mm

Machine Weight 100kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

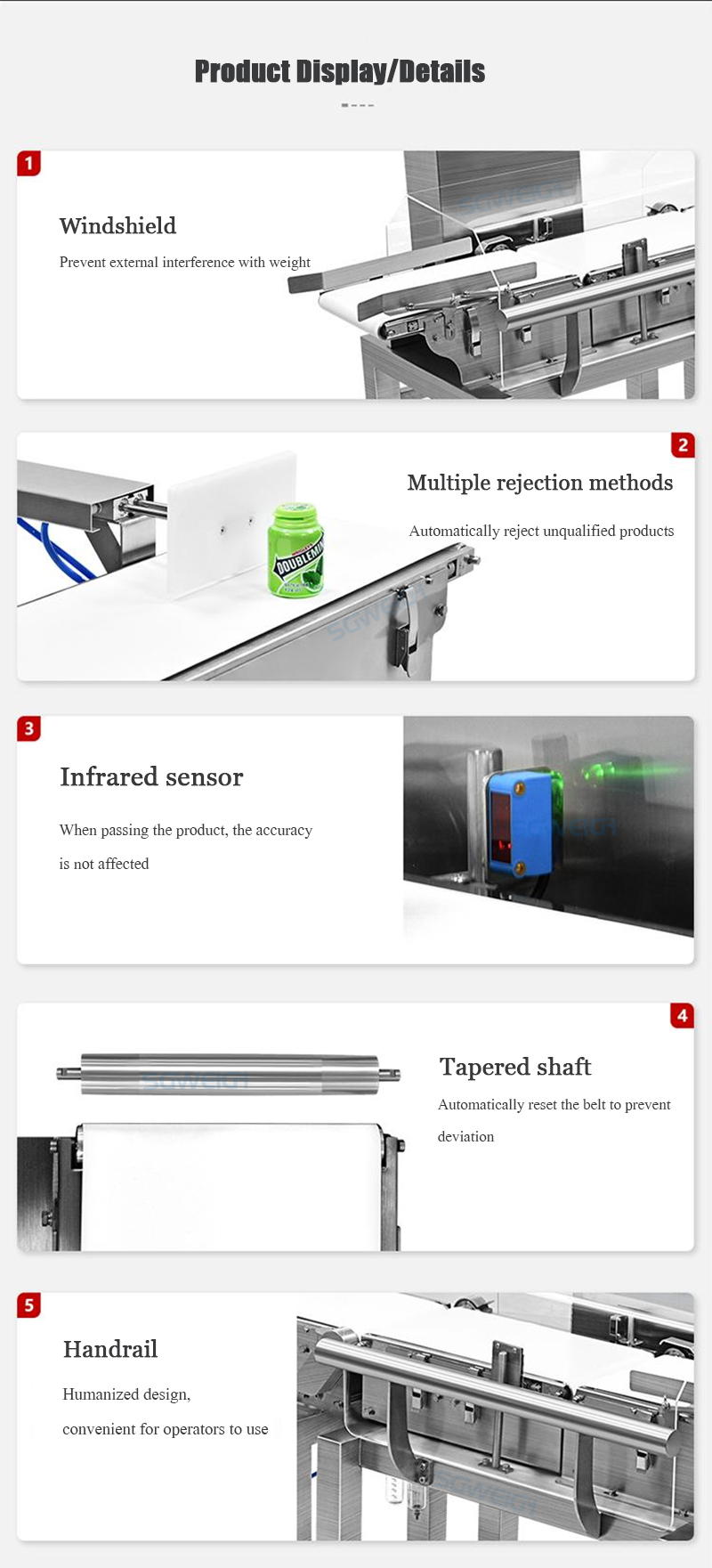

Main Advantages

1. Large-size color LCD touch screen interface, simple operation and intuitive display.

2. Support multiple languages: Chinese, English, Spanish, Italian, Japanese, Korean, etc. (customer specified), the default is Chinese and English.

3. It can store 200 kinds of product inspection data, which is convenient for users to call.

4. USB data storage interface, which can transfer report data to PC for analysis and printing.

5. Parameter setting password protection, only management personnel operate.

6. Automatic zero tracking system to ensure reliable detection data.

7. Built-in temperature and noise compensation system to ensure system stability. Online printing function (customization required).

8. Data external communication interface, which can be connected to other equipment in the production line (eg: labeling machine and inkjet printer) (customization required).

9. Multiple rejection devices: push rod rejection, fall rejection. (Customer required).

10. Simple mechanical structure, easy to disassemble, clean and maintain.

Application

Assemble line automatic checkweigher is mainly used for automatic weight detection, upper and lower limit discrimination or weight classification selection on various automated assembly lines and logistics conveying systems. It is widely used in online detection in the pharmaceutical, food, toy, hardware, chemical and other industries. In addition, it can directly replace manual weighing to improve production efficiency, consistency and reliability of weighing.

Our Customer

About Us

About our company

1. Founded in 2010.

2. Shanghai High-tech Enterprise.

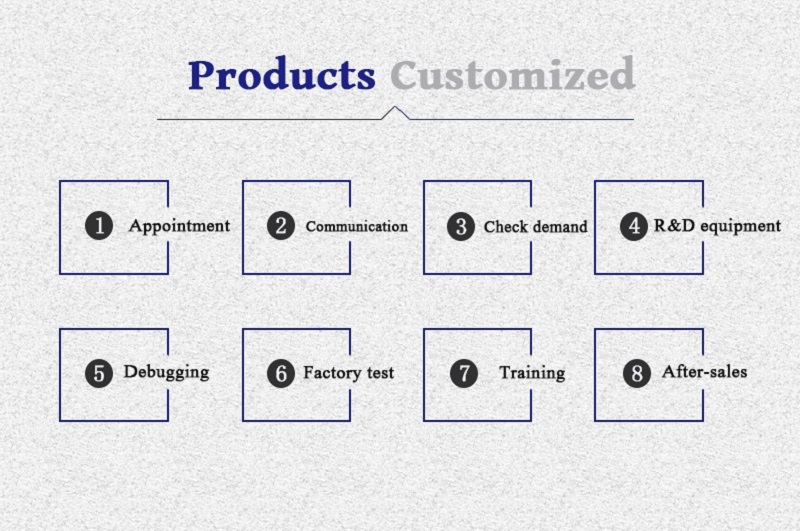

3. We have more than 10 years of experience in the field of packaging machinery, and have our own factory, which can provide you with the most suitable project for your needs.

4. 6-8 international machinery exhibitions every year.

5. Supply OEM/ODM manufacturing.

6. Multiple engineers to ensure quality/service.

7. As a manufacturer and trader, we have very good quality and price control of our products.

8. The products are exported to more than 40 countries including the United States, Canada, Mexico; Australia, New Zealand; Saudi Arabia, Italy, Spain; France, Poland, Israel, Russia, South Korea; Thailand, Indonesia, Malaysia, the Philippines, etc.

After Sale Service

1. Service tenet: fast, decisive, accurate, thoughtful and thorough

2. Service goal: service quality wins customer satisfaction

3. Service efficiency: If the equipment fails during the warranty period or outside the warranty period, our company will arrange maintenance personnel to provide maintenance services for customers within 24 hours after receiving the notice.

4. Service principle: The product warranty period is one year. During the warranty period, our company will repair the parts damaged due to quality reasons for free. If the parts are damaged outside the warranty period, only the cost will be charged for the accessories provided. If due to human factors If the equipment is damaged, the parts repaired or provided by our company are calculated at the cost price.

Related Products

Bottled Boxed Bagged Medicine Metal Detector

Supply High-speed Multi-column Packaging Machine

Digital Metal Detection Machine

Capsule Tablet Checkweigher Machine

Food Checkweigher Manufacturer

Hot Labels:carton,assembly line,belt,checkweigher,quantitative,check weigher,alarm,checkweigher

This pharma bottle checkweighe...

View MoreThis metal detector + weight c...

View MoreLeveraging advanced load cell ...

View MoreThis auto checkweigher with du...

View MoreThis inline metal detector for...

View MoreThis sensitivity metal detecto...

View More