The high accuracy checkweigher is designed for fully automatic packaging lines. When overweight or ultra light products are found, the conveyor belt will stop and alarm, and the screen will display the weight. Automatic quantitative blister checkweighers can achieve high-speed and high-precision weight detection to improve production efficiency, reduce labor, and lower costs.

Assembly Line Quantitative Blister Checkweigher High Accuracy Weight Checker Conveyor

The high accuracy checkweigher is designed for fully automatic packaging lines. When overweight or ultra light products are found, the conveyor belt will stop and alarm, and the screen will display the weight. Automatic quantitative blister checkweighers can achieve high-speed and high-precision weight detection to improve production efficiency, reduce labor, and lower costs. Our products have a wide range of specifications, sizes, and styles, providing various customized solutions. Welcome to contact us.

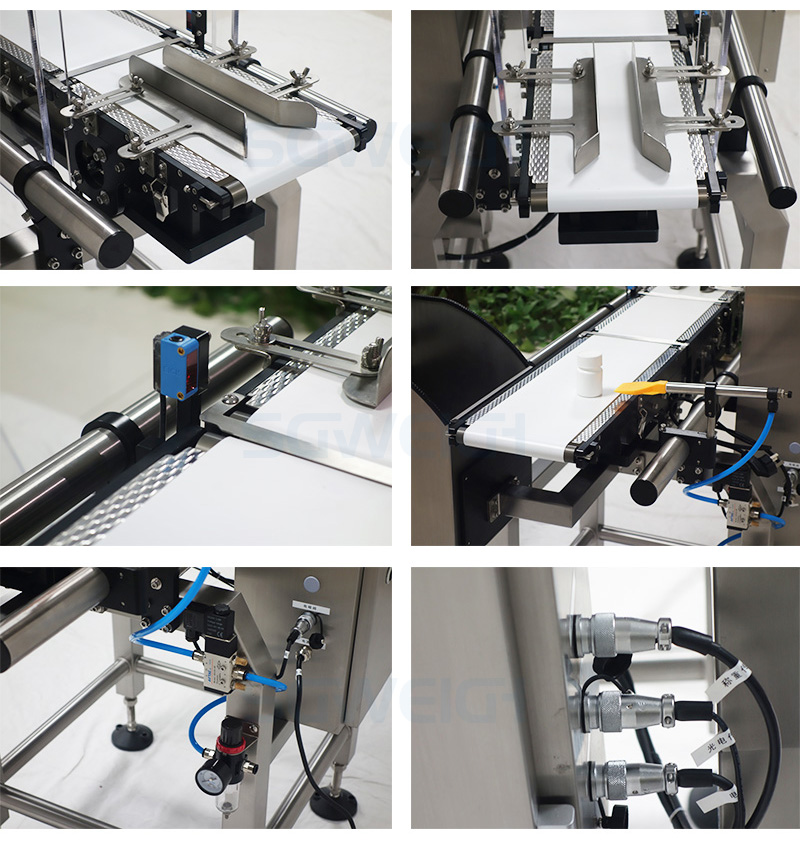

High accuracy blister checkweigher photos

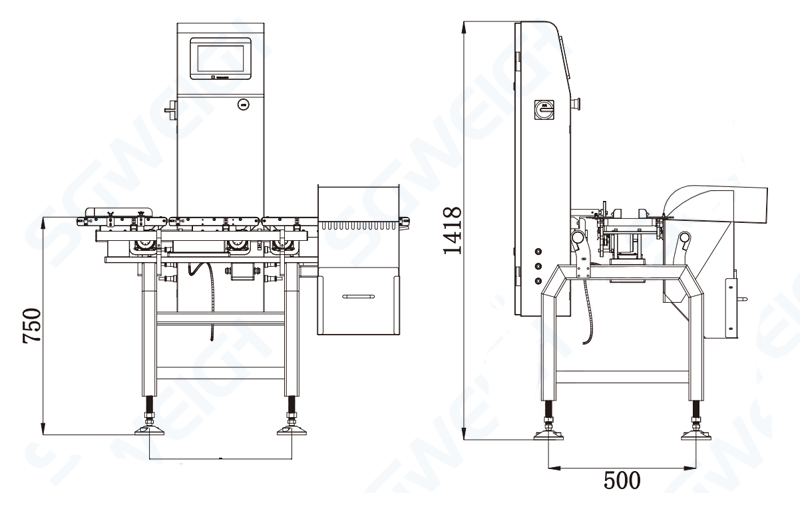

Type SG-100

Weighing Range 2-300g

Limited of product L: 100 W: 100 H: 2-150mm

Accuracy ±0.05g Depends on product

Division Scale 0.01g

Belt Speed 0- 90 m/min

Max Speed 260 pcs/min

Belt Width 100mm

Machine Weight 70kg

Power Supply AC 220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

1. High precision: Advanced sensor technology is used to achieve high-precision weight measurement, ensuring the accuracy of measurement results.

2. High speed dynamic processing: Adopting a high-speed processing chip, it can quickly respond and handle weight changes, achieving efficient detection.

3. Intelligence: With adaptive adjustment function, it can automatically adjust according to the different characteristics of the item, ensuring the accuracy and reliability of each weighing result.

4. Stability: Stable operation, not easily affected by external environmental interference, ensuring stable equipment operation.

5. Easy to operate: The user-friendly interface makes the operation more intuitive and convenient, making it easy to get started.

6. Diverse functions: capable of detecting overweight and underweight bags, missing bottles, cans, and parts in the entire box, as well as automatic removal of non-conforming products and sound and light alarm functions.

7. Visualization and data management: Modern weighing scales are usually equipped with touch screens or display screens to achieve real-time display and recording of data, facilitating analysis and management.

8. The high accuracy checkweigher has made significant progress in miniaturization, intelligence, and precision, and has a high cost-effectiveness.

9. The high accuracy checkweigher also has patented technology.

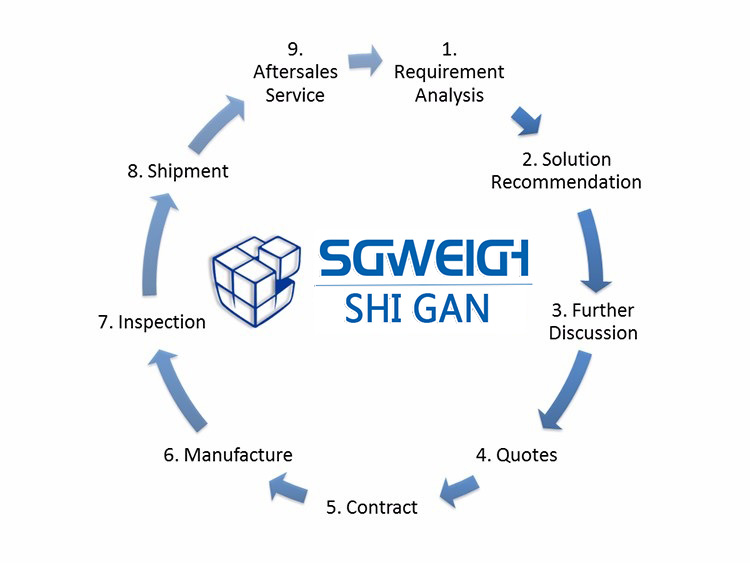

Most of our products are customized according to specific project requirements.

If possible, please provide us with more detailed information about your project, such as materials, weight range, speed, bag size, etc.

It is best for you to contact us in advance before placing an order.

High accuracy checkweigher is widely used in industries such as food, medicine, packaging, printing, logistics equipment, IT digital, home appliances, stationery and toys, precision manufacturing, agricultural product processing, etc. for dynamic weighing, missing parts, multi item detection, and multi-level sorting.

1.14 years of experience in checkweigher, metal detector manufacturing.

2. Over 14 years of technical team building, with a high-quality team consisting of over 30% of professional technical personnel. Product design updates and rich experience in personalized product industry requirements.

3. A professional foreign trade team with a sales team of over 20 people, each employee with rich market sales experience, providing high-quality pre-sales online communication services.

4. A professional after-sales service team with a 1-year warranty period, willing to establish long-term cooperative relationships with every customer.

5. We cooperate with multiple logistics companies to safely and quickly deliver goods to customers, minimizing their logistics costs.

6. Regularly participate in large-scale industry exhibitions in various regions and have the ability to negotiate cooperation with regional partners.

1. Equipment installation and debugging: The company provides detailed operation manuals and free operation training to ensure that customers can proficiently use the equipment.

2. Technical support: The company provides 24/7 technical support to solve problems encountered by customers during use.

3. Accessories supply: The company provides original accessories to ensure the quality and stability of the accessories.

4. Quality assurance: The company is responsible for the products sold, ensuring that the quality and performance of the equipment meet industry standards.

5. Warranty policy: One year warranty, lifetime repair, to solve customers' worries.

Related Products

Dynamic Industrial Checkweigher Metal Detector Combo

Shrimp Multi-stage Weight Sorting Checkweigher for Seafood

Hardware Screw Bag Checkweigher Packaging Lines

Multifunctional Multi-lane Checkweigher for Small Sachet

Falling Capsule Tablet Metal Detector Vertical

High Speed Dynamic Checkweigher for Bottle

Hot Labels: assembly line,quantitative,blister,checkweigher,high accuracy,weight checker,conveyor,factory,price

This sensitivity metal detecto...

View MoreThis high-speed boxed cigarett...

View MoreThis dynamic checkweigher for ...

View MoreThis capsule tablet weighing s...

View MoreThis bottle metal detector for...

View MoreThe automatic capsule metal de...

View More