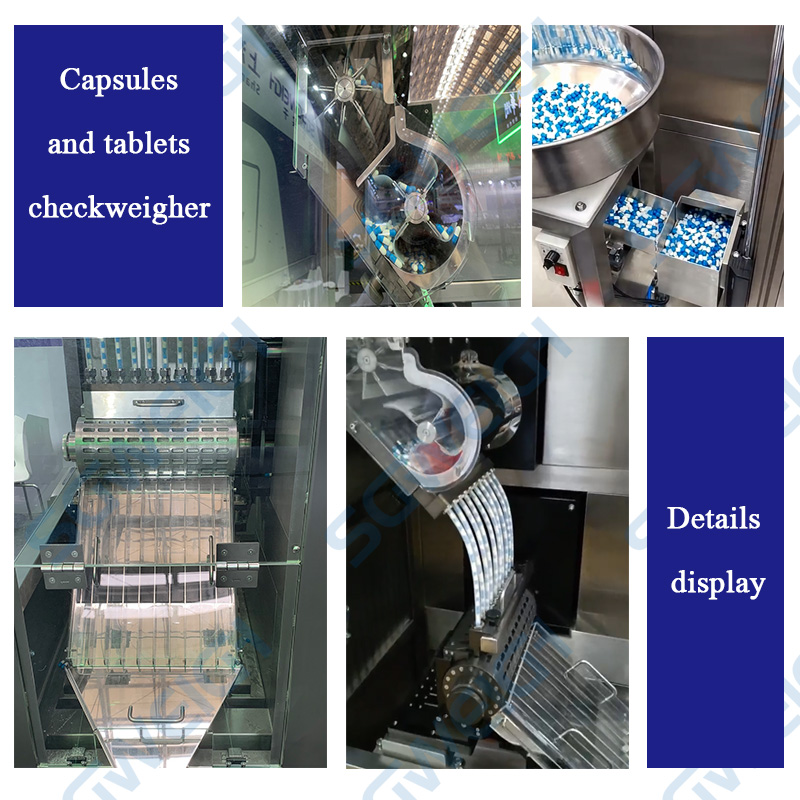

This tablet capsule checkweighers for pharmaceutical uses an innovative model to infinitely improve the inspection efficiency. It can fully weigh capsules and tablets of different quantities and grades, and quickly eliminate products with unqualified weights. This automatic vertical mass tablet capsule checkweighers measures data quickly, operates stably, and has strong resistance to environmental interference, so that its high-speed model can meet the online weighing needs of large-scale production in workshops.

Vertical Mass Tablet Capsule Checkweighers for Pharmaceutical Production

This tablet capsule checkweighers for pharmaceutical uses an innovative model to infinitely improve the inspection efficiency. It can fully weigh capsules and tablets of different quantities and grades, and quickly eliminate products with unqualified weights. This automatic vertical mass tablet capsule checkweighers measures data quickly, operates stably, and has strong resistance to environmental interference, so that its high-speed model can meet the online weighing needs of large-scale production in workshops. Our products have a wide range of specifications, sizes, and styles, providing various customized solutions. Welcome to contact us.

Tablet capsule checkweighers for pharmaceutical photos

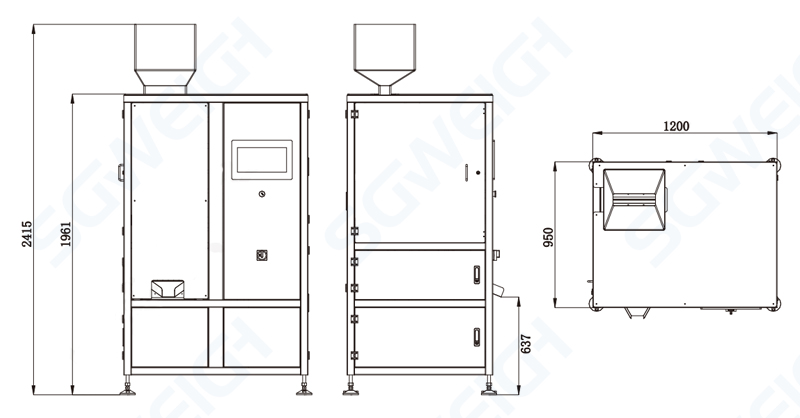

Type:SG-JN10/SG-JN20/SG-JN30

Weighing scope :5-2000mg

Display scale:0.1mg

Highest sorting accuracy:±0.5mg

Product specification:Capsule-00#-5#/Wafer-Φ5.5-Φ18mm/Thickness-3-12mm/Pill-Φ5.5-Φ12mm(Other sizes or shapes subject to testing)

Highest sorting ability :75000 PCS/HR/150000 PCS/HR/230000 PCS/HR

Number of columns:10 Columns/20 Columns/30 Columns

Power supply:AC-220V±10%, 50HZ

Compressed air:0.3-0.9Mpa

Use environment:15~30°C (The temperature change during use should not exceed the range of 1°C/h.Hunidity:30-70%(but no condensation)

Weight of Machine :350kg/500kg/700kg

Shell material:SUS304

1. Weight Measurement: A checkweigher measures the weight of each capsule, tablet, or pill as it moves along the production line. It compares the measured weight to a predefined weight range to determine if the product is within an acceptable range.

2. High-Speed Operation: Designed for high-speed operation, these checkweighers can weigh hundreds or even thousands of units per minute, depending on the model.

3. Accuracy: Precision is critical in pharmaceutical applications. These checkweighers typically offer high accuracy, often down to the milligram, to ensure compliance with stringent industry standards.

4. Advanced Sensors: Equipped with high-precision load cells or electromagnetic force recovery sensors, they can accurately detect even the slightest changes in weight.

5. Automatic Rejection: Products outside the acceptable weight range are automatically rejected from the production line, ensuring that only products that meet requirements make it to the packaging stage.

6. Data Logging: Many tablet capsule checkweighers for pharmaceuticals have data logging capabilities, allowing manufacturers to track performance, record weight data, and generate quality control and regulatory compliance reports.

7. User Interface: Modern tablet capsule checkweighers for pharmaceuticals feature intuitive touchscreens or other user-friendly interfaces for easy operation, calibration, and parameter adjustment.

8. Compact Design: These machines are typically compact and can fit into existing production lines with minimal disruption.

Vertical Mass Tablet Capsule Checkweighers for Pharmaceutical Production

Tablet capsule checkweighers for pharmaceutical can detect all types of capsules such as 000 00 0 1 2 3 4 5 SA, SB, and conventional tablets;

1st step: Customer has showed his special requirements.

2nd step: We try to understand the conception and pattern from customer with simple draft or refer picture.

3rd step: Making the conceptive CAD drawing based on communication and understanding.

4th step: Making the detail and 3D drawing agter fixed the design and other details.

5th step: Offer the quotation after confirm the design,material and surface treament.

6th step: Making the sample for approval.

7th step: Testing installation after demo mock up.

8th step: Big production delivery and service after sales.

Vertical Mass Tablet Capsule Checkweighers for Pharmaceutical Production

Packaging

Film pack inside, Wooden case outside

Shipping

1. Customer consultation and technical support: Provide customers with consulting services on product use, repair and maintenance, and answer questions encountered by customers during operation and use.

2. Technical training: Provide training on product operation, maintenance and repair according to customer needs to ensure that customers can use and maintain the products correctly.

3. Accessories supply: Provide original accessories to ensure the quality and performance of accessories to meet user needs.

4. One-year warranty, lifetime maintenance

6. After-sales service tracking: Track and feedback the after-sales service process, timely understand customer needs and opinions, and continuously improve service quality.

Related Products

Checkweigher for Food industry

Checkweigher for the pharmaceutical industry

Checkweigher for Cosmetics industry

Checkweigher for Daily Necessities

Checkweigher for Hardware fitting

Checkweigher with metal detector

Digital Metal Detection Machine

Hot Labels: vertical,mass,tablet,capsule,checkweighers,pharmaceutical,production,manufacturer,supplier,factory,price

The rotary checkweigher for be...

View MoreThis pharmaceutical packaging ...

View MoreThis dual-lane checkweigher fo...

View MoreThis high-speed bottle weighin...

View MoreThis daily necessities packagi...

View MoreThis online weight checker for...

View More