Dynamic weight detection checkweigher is a machine that is based on a single packaging product (assembly line type). It is usually used for the middle or end of the assembly line. The weight of semi -finished products and finished products is detected. All products that do not meet the set weight (or weight deviation) will be automatically removed. The fast and slow speed of dynamic weight checker with sound and light alarm depends on the size of the weighing product and the range of acceptable errors (accuracy).

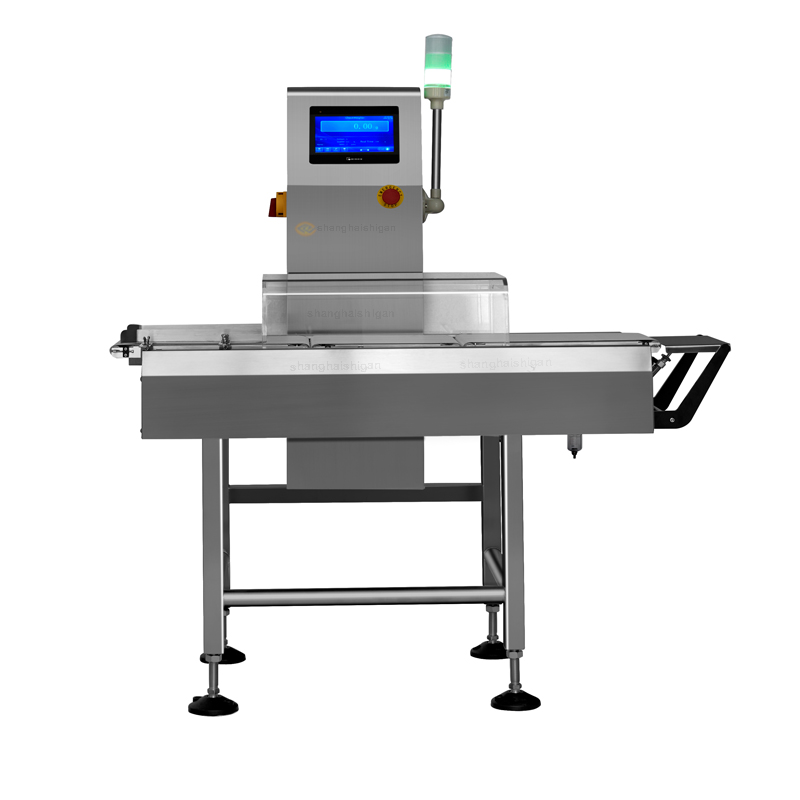

Simple Quick Pouch Weight Detection Checkweigher Weight Checker With Sound And Light Alarm

Dynamic weight detection checkweigher is a machine that is based on a single packaging product (assembly line type). It is usually used for the middle or end of the assembly line. The weight of semi -finished products and finished products is detected. All products that do not meet the set weight (or weight deviation) will be automatically removed. The fast and slow speed of dynamic weight checker with sound and light alarm depends on the size of the weighing product and the range of acceptable errors (accuracy).For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

Dynamic weight detection checkweigher pictures

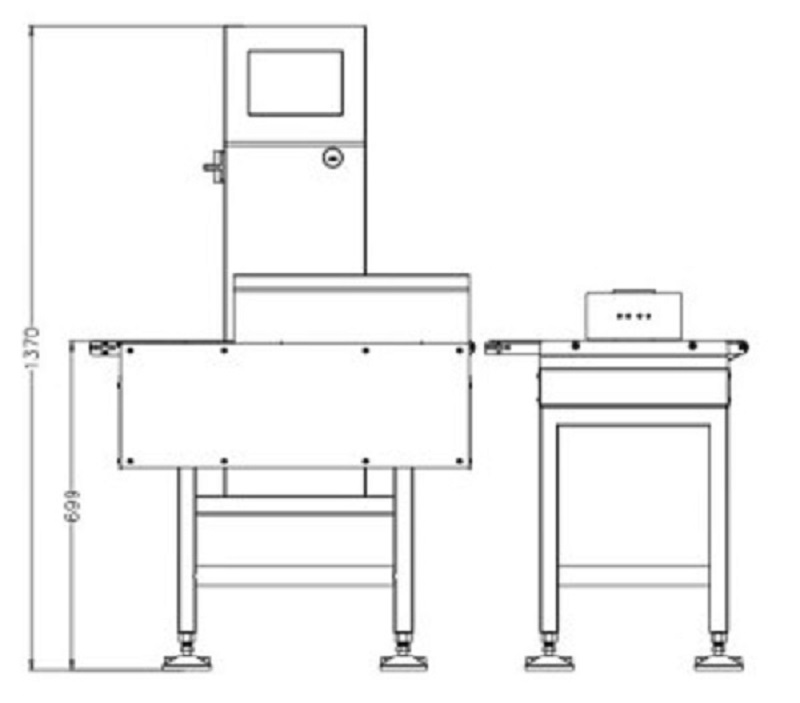

Type SG-220

Weighing Range 5-1500g

Limited of product L: 300 W:220 H: 3-200mm

Accuracy ±0.2g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 100 pcs/min

Belt Width 220mm

Machine Weight 60kg+44kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

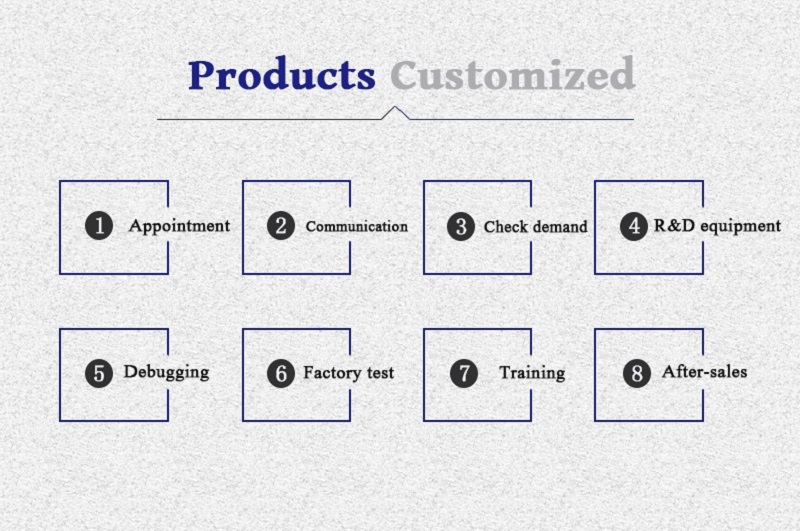

The above specifications are for reference only, and can be customized according to the requirements. Other devices in the production line can also be connected.

1. Connect to the packaging machine, the packed and packaged products can directly detect whether the net content is qualified

2. Connect the scanner and inkjet printer, which can print the production date, production batch number, and product weight on the product.

3. Connect the printer, and do not output weight values and daily production and production status according to the product.

4. Connect the metal detection machine, which can be continuously detected whether the product contains metal foreign objects

5. Connect the label to achieve real -time printing and paste label

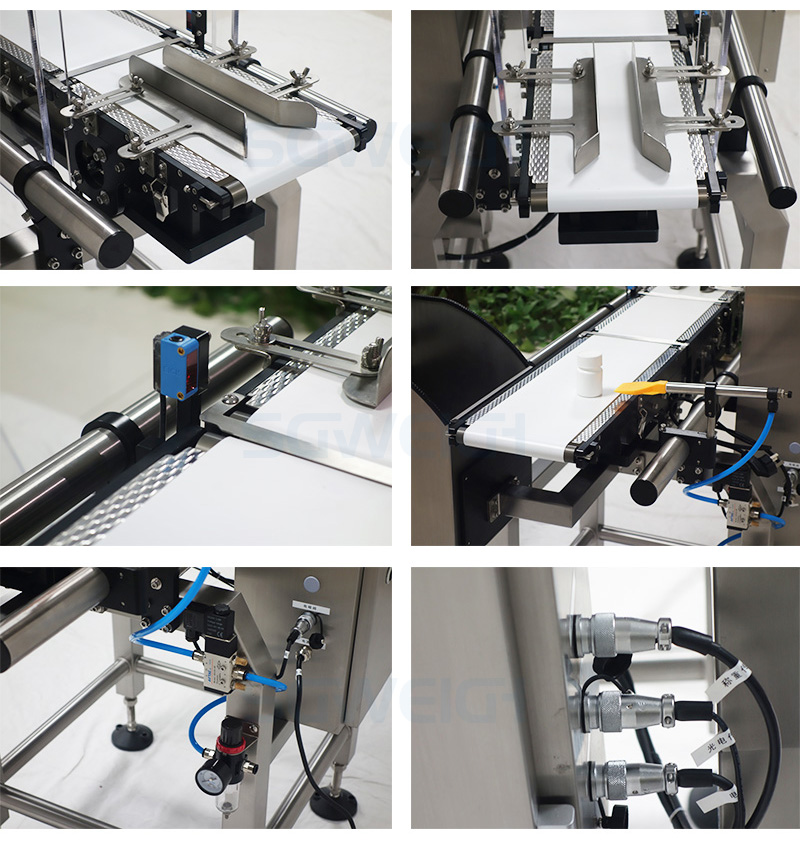

1. Long -term use, accuracy guarantee, no need to calibrate daily

2. Automatic dynamic zero tracking technology

3. Use built -in hinge design, no safe dead ends, quickly installation and disassembly of the belt, easy to clean and maintain

4. Professional human -machine interface design

5. Simple user parameter settings, automatic parameter adjustment, just enter product parameters and claims, you can complete the parameter settings

6. Accurate and efficient removal agency

7. Humanized function, product database can store 10,000 products

8. Password protection function to ensure that non -authorized personnel cannot change data

9. With data statistics, support data export, USB and Ethernet interface

1. Food industry

Automatic dynamic inspection heavy machines can solve insufficient net weight of packaging food/overweight detection, packaged food full box/full bag/full box/whole packaging lack

2. Medical industry

High -precision testing heavy scale can solve whether the pharmaceutical industry detects less grain and multiple grains; whether the pink bag is lacking and multiple bags; whether the weight of liquid drugs meets the standard requirements; Wait).

3. Cosmetics industry

The quality control problem of automatic weighing weighing and packaging production line inspection. Check whether the mask is missing, bags, and cosmetics meet production requirements, whether the product is complete, etc.

4. Daily industry

The test heavy scale is used to detect the number of single items in the products in bags, bags, boxes, bottles, cans, boxes, and other products, such as the lack of bottle, the whole box, the whole box, the whole bag, the whole bag, the whole bag, the whole bag, Wait.

5. Hardware industry

Online inspection heavy machines can detect product quality inspection of various metal stamping parts, die castings, processing containers, precision pieces, spare parts and other products, and weighing and classification of building materials products.

Our manufacturer has ISO9001, CE international certification,

1. Service purpose: fast, decisive, accurate, thoughtful, thorough

2. Service goals: service quality win user satisfaction

3. Service efficiency: During the warranty period or out -of -war period, such as faults. After receiving the notice, our company arranges maintenance personnel to provide maintenance services for customers within 24 hours.

4. Service Principles: The product warranty period is one year. During the warranty period, our company will be damaged by components caused by quality reasons for quality reasons. The device caused by damage, the maintenance or accessories provided by our company are calculated at the cost price.

Related Products

High Speed Spices Powder Auger Filler Packaging Machine

High-precision Intelligent Particles Multi-head Scale

Cartons Heavy-Duty Weighing Equipment Bengal

Economical Metal Detector with IP 69 Rating

Online 50kg Cement Check Weighing System

Logistics Roller Sorting Inspection Checkweigher Scale

Hot Labels:simple,quick,pouch,weight detection,checkweigher,weight checker,sound and light alarm,manufacturer,factory,price

The pharmaceutical capsules sa...

View MoreMulti-stage checkweigher for w...

View MoreThe high load assemble line ch...

View MoreThe online soft hard capsule c...

View MoreThe unique low center of gravi...

View MoreThe high accuracy checkweigher...

View More