Dynamic bottle checkweighers are automatic devices used to check product weight in automatic packaging production lines. They can check whether the weight of the product meets the standard weight we set during continuous working process. In addition, checkweighers can automatically reject unqualified products. This series of professional automatic checkweigher is modularly designed and highly flexible, providing a full range of functions for handling different products and incorporating new functions to cope with modern needs.

Professional Dynamic Bottle Checkweighers for High Speed Precision Weighing

Dynamic bottle checkweighers are automatic devices used to check product weight in automatic packaging production lines. They can check whether the weight of the product meets the standard weight we set during continuous working process. In addition, checkweighers can automatically reject unqualified products. This series of professional automatic checkweigher is modularly designed and highly flexible, providing a full range of functions for handling different products and incorporating new functions to cope with modern needs. We welcome all of our distinguished guests to contact us freely.

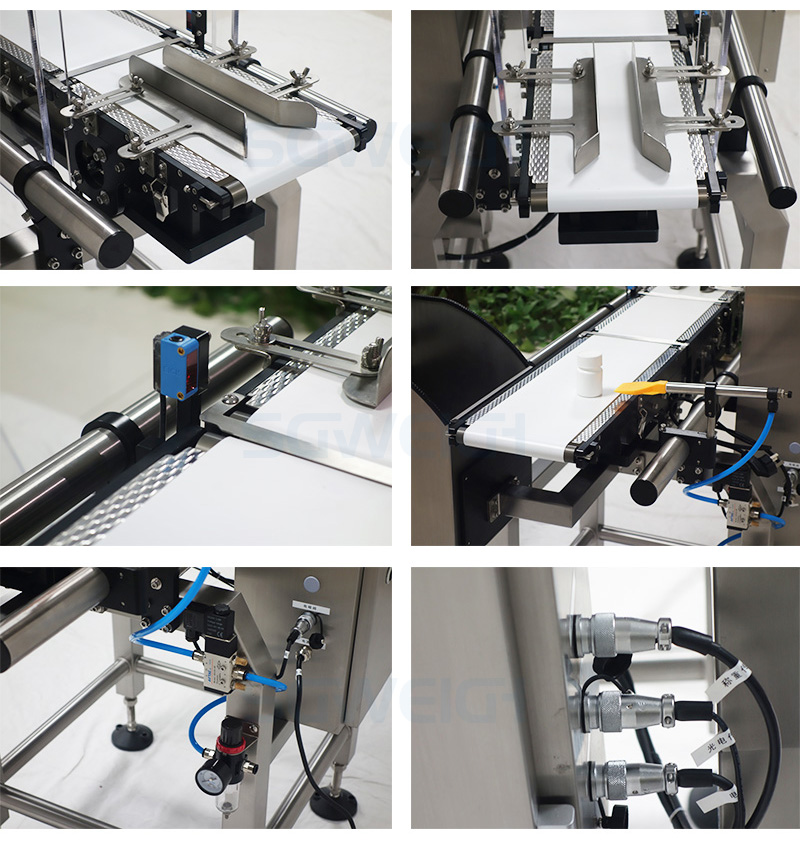

Dynamic bottle checkweighers photos

Professional Dynamic Bottle Checkweighers for High Speed Precision Weighing

Dynamic bottle checkweigherss have grown into the weight part of production operations and management. Their functions are not only online weighing and testing, but can also help production users optimize the entire production process:

1. 100% online inspection of each product to avoid penalties caused by poor quality

2. Feedback parameters to front-end packaging equipment through weighing and testing

3. Optimize and improve production processes, improve equipment operation efficiency and save production materials

4. Reduce manual missed inspections, mis-inspections and quality rework, and maintain product and brand reputation

5. Save labor, increase quality inspection rate, and comprehensively improve product quality

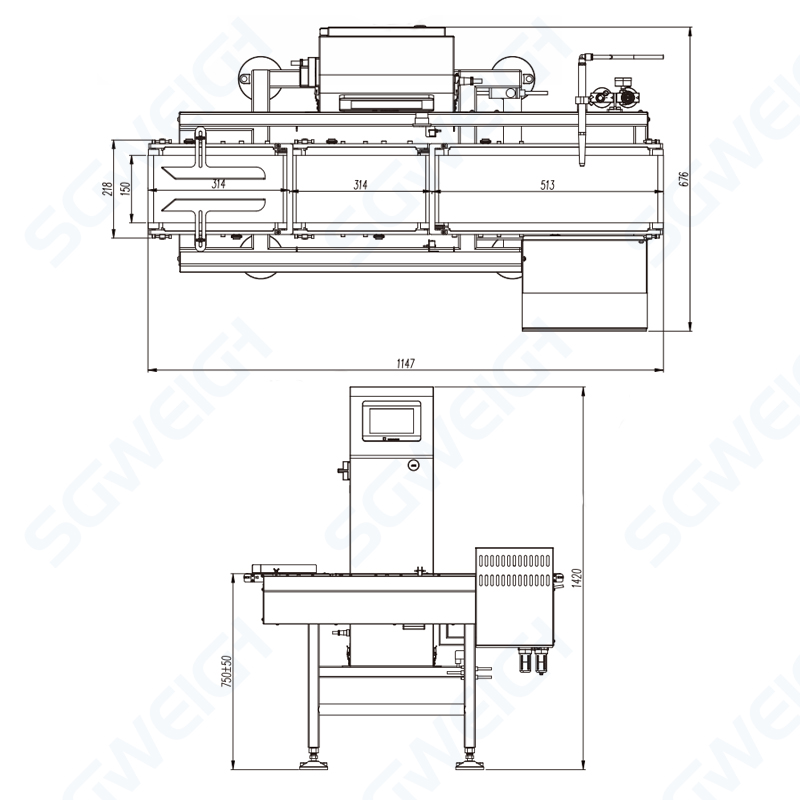

Type SG-150U

Weighing Range 3-500g

Limited of product L: 100 W:150 H: 3-200mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 150 pcs/min

Belt Width 150mm

Machine Weight 60kg

Power Supply AC 220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

Dynamic bottle checkweighers are suitable for checking whether the weight of a single product is qualified or whether the product is packaged. Whether there is any omission in the process, it is widely used in many industries such as pharmaceuticals, food, beverages, electronics, health products, daily chemicals, light industry, agricultural and sideline products, etc.

How to select dynamic bottle checkweighers?

First, determine the series according to the size, weight range and purpose of the products you need to sort.

For example, if the weight is less than 300g and the size is 150*90*30mm, choose model SG-150, belt width 150mm and range less than 500g.

Second, determine the level you need to sort, whether it is three levels or five levels. Different levels have different prices. The more levels, the higher the price. At present, our factory can sort up to 12 levels.

Third, determine the height and width (if any) of your existing assembly line, and the space required by our company.

Fourth, determine the functions you need to select; such as USB storage data, real-time transmission of weight data, alarm, etc.

In order to provide more accurate parameters, solutions and quotations, it is recommended that you contact the person in charge of our company to help you complete the selection.

Professional Dynamic Bottle Checkweighers for High Speed Precision Weighing

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

1. Service Purpose: Shanghai Shigan Industrial Co., Ltd. is committed to providing customers with fast, decisive, accurate, thoughtful and thorough services to meet customers' needs in equipment.

2. Service Objectives: The company takes high-quality service quality as the standard, aiming to win the satisfaction and trust of users.

3. Service Efficiency: The company promises that once the equipment fails, it will provide an effective solution within 24 hours to ensure that the customer's production progress is not affected.

4. Service Principles: The warranty period of the company's products is twelve months. During the warranty period, for equipment damage caused by quality reasons, the supplier will provide free repairs and replacement parts. For equipment parts damaged outside the warranty period, the supplier will only charge the cost price. For equipment damage caused by customer human factors, the supplier's repair or parts provision will be calculated at cost.

Related Products

Digital Metal Detection Machine

Metal Detector for Pharmaceutical

Metal Detector for Daily Necessities

Metal Detector for Other Industries

Checkweigher and Metal Detector Combo

Multi-stage Sorting Checkweigher

Hot Labels: professional,dynamic,bottle,checkweighers,high speed,precision weighing,manufacturer,supplier,price

Industrial Gravity-Fall Metal ...

View MoreThis integrated weighing and m...

View MoreHigh-Sensitivity Compact Metal...

View MoreThis compact checkweigher for ...

View MoreThis high-precision industrial...

View MoreThis high speed liquid stick m...

View More