Multi-stage checkweigher for food is mainly used in various automatic assembly lines, aquatic products, food and other industries. It is used to sort products at multiple levels through automatic weighing. Food conveyor belt weight sorting machine can directly replace manual weighing to improve production efficiency, improve accuracy, reduce labor and reduce costs. Improve the product safety factor and improve the product quality of the enterprise.

Multi-stage Checkweigher For Sashimi Food Conveyor Belt Weight Sorting Machine For Weight Control

Multi-stage checkweigher for food is mainly used in various automatic assembly lines, aquatic products, food and other industries. It is used to sort products at multiple levels through automatic weighing. Food conveyor belt weight sorting machine can directly replace manual weighing to improve production efficiency, improve accuracy, reduce labor and reduce costs. Improve the product safety factor and improve the product quality of the enterprise. Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

Multi-stage checkweigher for food photos

1) Efficient and economical: multi-level sorting and automatic weighing can replace manual work and improve efficiency;

2) Strong versatility: the standardized structure of the whole machine and the standardized human-machine interface can complete the weighing of various materials

3) Multi-level expansion: 2-12 levels of sorting can be customized according to customer needs;

4) Clear and sensitive: imported high-definition color touch screen, multiple voice pictures, and clear information at a glance;

5) Professional and easy to use: professional weighing scale system has rich functions, simple operation, and multiple weighing data statistical formats to meet the needs of various production data;

6) Extensive expansion: a variety of sorting methods can be selected, and various expansion equipment can be added according to customer needs;

7) Convenient maintenance: fast detachable structure design, convenient cleaning and maintenance;

8) Beautiful and durable: 304 stainless steel, or high-strength aviation aluminum body; Ensure the stability of long-term operation.

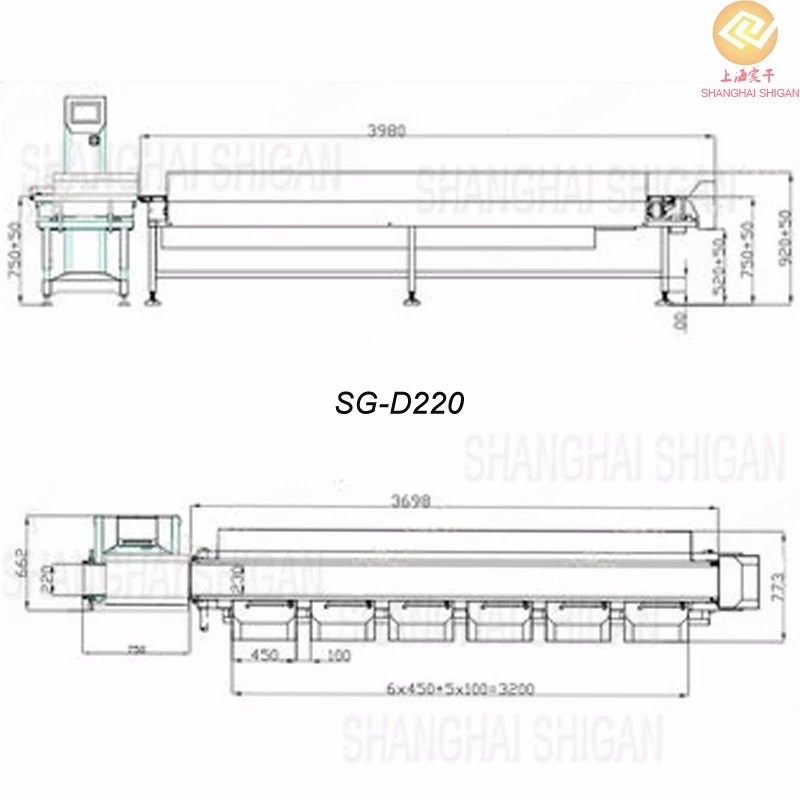

Type SG-D220

Weighing Range 10-1200g

Limited of product L: 200 W:150 H: 3-200mm

Accuracy ±0.2 Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 100 pcs/min

Belt Width 220mm

Machine Weight 60kg+44kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

1st step: Customer has showed his special requirements.

2nd step: We try to understand the conception and pattern from customer with simple draft or refer picture.

3rd step: Making the conceptive CAD drawing based on communication and understanding.

4th step: Making the detail and 3D drawing agter fixed the design and other details.

5th step: Offer the quotation after confirm the design,material and surface treament.

6th step: Making the sample for approval.

7th step: Testing installation after demo mock up.

8th step: Big production delivery and service after sales.

■ Automatic multi-stage checkweigher series equipment:

1) Seafood classification: sea cucumber, abalone, squid, shellfish and other seafood. The automatic multi-level weighing scale will automatically classify the seafood according to the scheduled weight and sort it into the designated category or grade device.

2) Aquatic products classification: fish, shrimp, crab and other aquatic products are classified according to their requirements through our automatic multi-level weighing scale series equipment.

■ Automatic multi-level check weighing scale: automatic sorting for different aquatic products.

■ Customized automatic multi-stage meat checkweigher: Shanghai Shigan will process and customize various automatic weighing scale solutions and equipment according to the actual needs of users.

Shanghai Shigan Industrial Co., Ltd. is located in beautiful Shanghai, China. Since 2010, it has been engaged in the production and development of assembly line packaging and weighing equipment, and has obtained CE certification and a number of professional certificates. The company has always adhered to the business philosophy of "innovation, quality and efficiency", providing you with perfect and high-quality products and services. Now our company's products have been sold all over the world, and have received the trust and praise of countless customers!

Our main products include: automatic checkweigher, digital metal detector machine, vertical packaging machine, premade bag packaging machine, multi-head weigher, linear scale, sub-packaging machine and a series of assembly line packaging detection equipment

1) Warranty period: 1 year. During this period, if there is any non-human damage to them, we will provide spare parts for replacement free.

2) Quality: The product quality will be strictly checked, and each machine will be tested before packaging to ensure that it can work normally.

3) Technical service: After the machine is sold out, we will keep in touch with customers. If you need any help on the machine, please do not hesitate to contact us.

4) Document service: We provide instructions and videos to teach you how to use and test the machine.

5) Accessories: We provide spare parts with competitive prices after the warranty period.

Related Products

Food and Pharma Industry Labeling Machines With Weighing

Drink Pouch Bag Sealing Packing Machine

High Accuracy Sugar Food Nuts Weighing Filling Machine

4 Lane 6 Lane Stick Bag Packing Machine OEM

Packing 25g Snack Foods 14 Multihead Heads Weigher

Mini Checkweigher Weight Inspection Conveyor

Hot Labels: multi-stage checkweigher,sashimi,food,conveyor belt,weight sorting machine,weight control,manufactuer,price,factory

A vertical capsules metal dete...

View MoreThe pharmaceutical capsules sa...

View MoreMulti-stage checkweigher for w...

View MoreThe high load assemble line ch...

View MoreThe online soft hard capsule c...

View MoreThe unique low center of gravi...

View More